Reliable hose connections in zone 1

A fully potted RFID HF reader identifies connections directly in Atex zone 1/21 and transmits data to Ethernet gateways in zone 2/22

Benefits

Valves open only after the correct hose connections have been identified

Reliable identification and documentation of upstream and intermediate products

Complete product traceability through end-to-end RFID usage

Comparison of specific RFID data instead of inductive binary code detection

Challenge

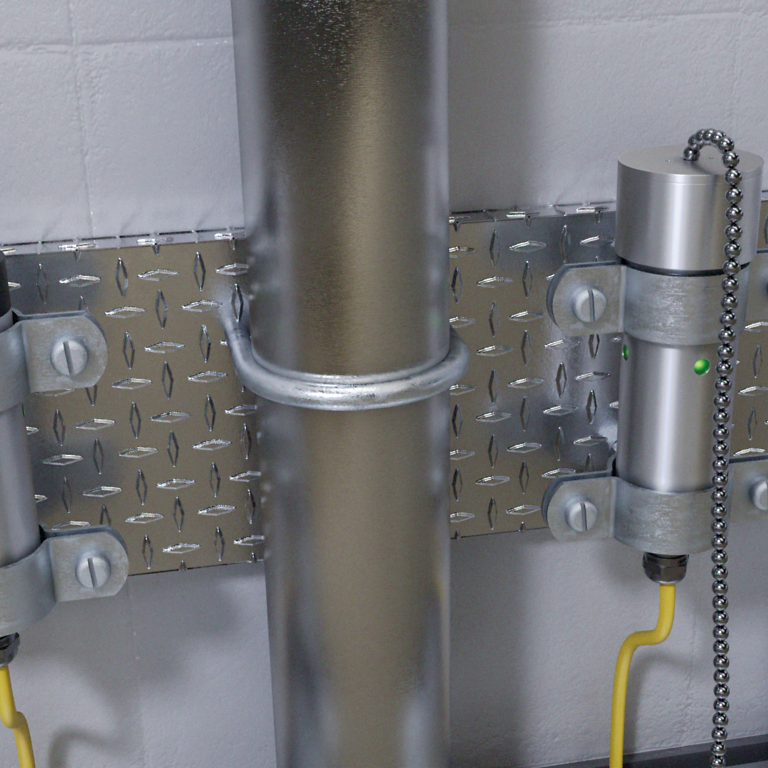

In the pharmaceutical industry, mixed-up or leaking media can have serious consequences for plant safety, product quality and employee health. If acid gets into the wrong tank, for example, this can result in a high risk of danger or significant financial damage. To avoid incorrect hose connections, the intended hoses must be reliably identified before the valve and pump are released.

Solution

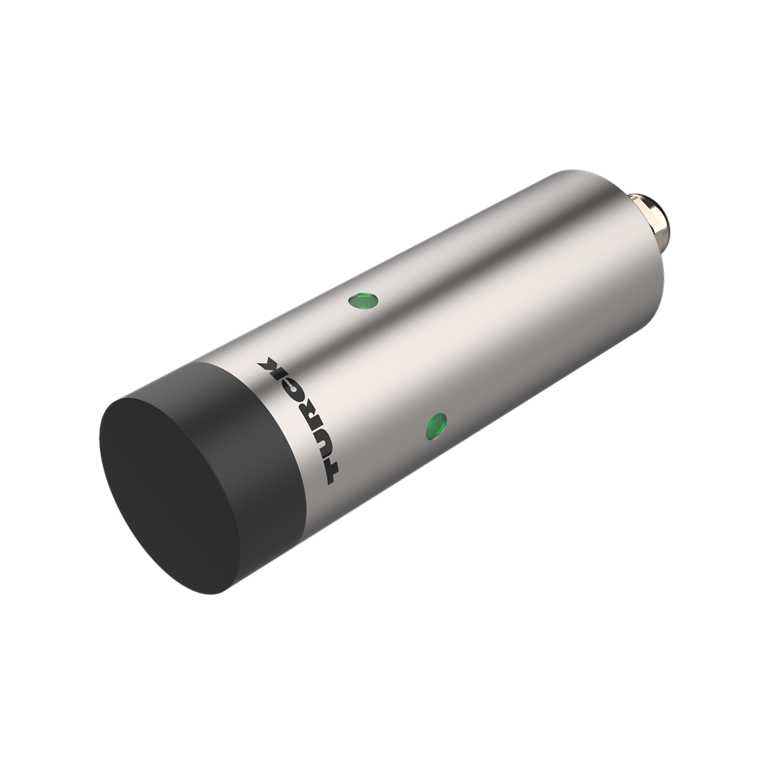

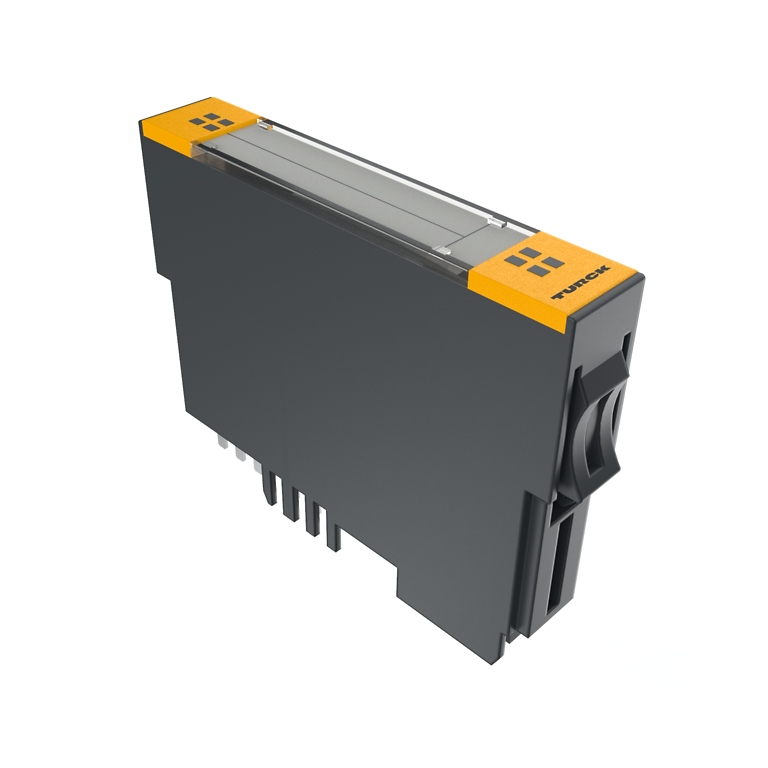

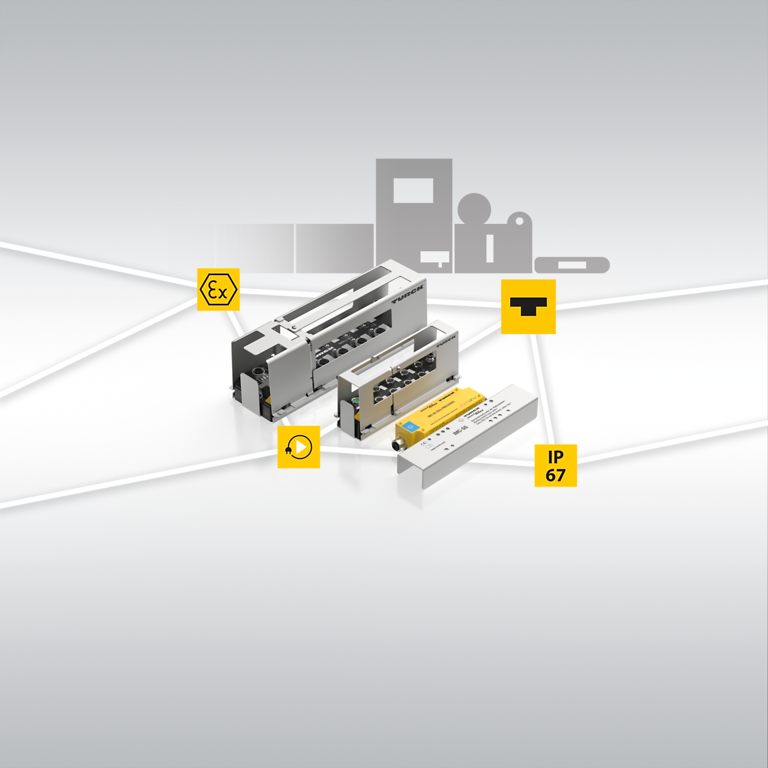

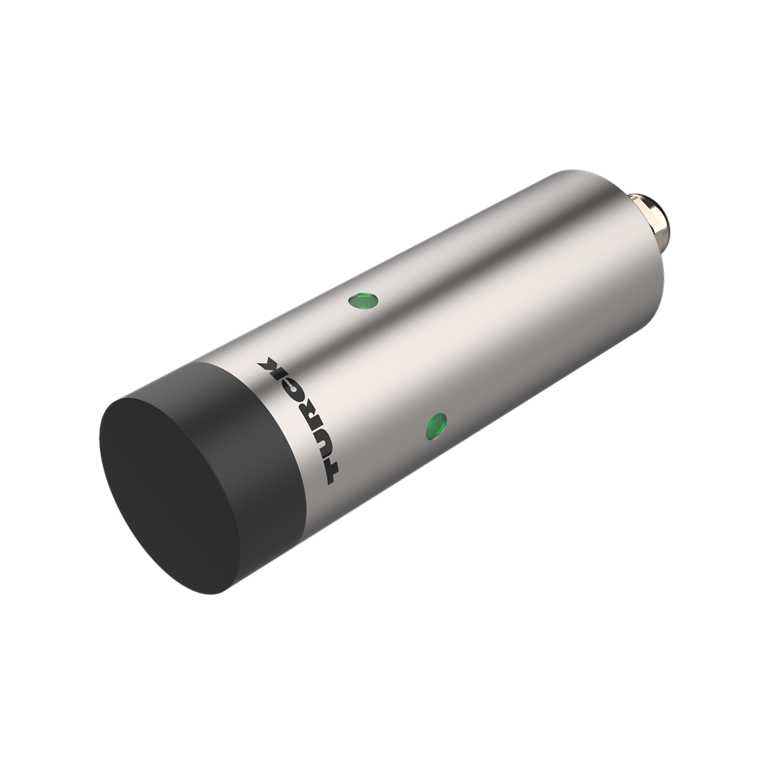

The encapsulated HF RFID reader TN-R42/TC-EX from TURCK enables the reliable identification of hose connections directly in potentially explosive areas (ATEX Zone 1/21). The reader detects the RFID tag attached to the end of the hose and checks whether the connection is correct. Only after successful identification is the valve opened to release the media. The recorded data is transmitted via cables more than 50 meters long to TURCK's IP67 RFID interfaces TBEN-S or TBEN-L. Thanks to its robust design, the reader can be installed in Ex zone 1/21, while the RFID interfaces are operated in zone 2/22 with special protective cages. Data communication takes place via multi-protocol Ethernet( Profinet , EtherNet /IP, Modbus TCP). Application-specific RFID tags are also available, including variants made of glass or with metal caps. This complete solution ensures error-free and traceable assignment of hoses and connection points, significantly improving safety and process control.

"Our RFID solution for hazardous areas ensures maximum process safety by reliably preventing incorrect hose connections. Its robust design makes it ideal for demanding applications in the pharmaceutical industry."

Thorsten Enthöfer | Product Manager RFID HF Systems | TURCK GmbH

Erfahren Sie mehr über unsere Produkte