Automatisierte Lagerverwaltung für Wafer dank RFID-System

TURCKs RFID-System BL ident koordiniert die robotergestützte Ein- und Auslagerung von Zwischenprodukten in der Halbleiter-Produktion in China

Quick read

A Chinese semiconductor controller automates the storage and removal of wafers between the production steps with RFID support, thus ensuring a smooth process flow. TURCK's BL ident® RFID system was selected, also because the modular system can be easily integrated into existing plant configurations.

Digitalization, and therefore microelectronics, is moving into all areas of life, which means that the semiconductor industry has developed into a motor for the global economy within a few years. In the midst of this boom, manufacturers face the challenge of meeting the ever-growing demand. Semiconductor production is a highly complex process consisting of hundreds of steps. Due to their size and complexity, it is virtually impossible to manufacture integrated circuits manually. In addition, production places high demands on purity, cleanliness and functionality. Accordingly, semiconductor factories require highly automated, intelligently networked as well as modular and flexible production concepts.

One of the world's leading semiconductor manufacturers in China faced the challenge of safely storing the delicate silicon wafers between quality testing and their packaging. The sensitive components must be stored temporarily in material racks until the next process step. In this process phase, the wafers were previously removed manually and the removal was documented on paper material sheets. This process was as time-consuming as it was error-prone and provided only a poor overview of the material flow in the overall process. As a result, an automated solution was required to guarantee a reliable and efficient process.

Consequently, the customer now relies on RFID in warehouse management to achieve error-free and consistently transparent production. The RFID storage location identification uses RFID tags to monitor which wafer is placed in which storage location during storage and removal from storage or transfer. All stored wafers can therefore be found immediately if necessary.

Robot-assisted RFID solution

In the automated processing of unprocessed wafers into integrated circuits, specialized high-performance handling robots play an essential role. These Automated Guided Vehicles (AGVs) with integrated robot arm navigate autonomously and ensure reliable handling of components between processes. In cooperation with a Chinese robotics company, TURCK developed a complete RFID solution to use an AGV for material transport. The solution significantly reduces the time required to feed the wafers and minimizes the amount of work required in this process step. The warehouse management system links the information from the RFID system with the information from the production control system (MES) and thus monitors all wafers in real time.

BL ident® RFID solution impresses

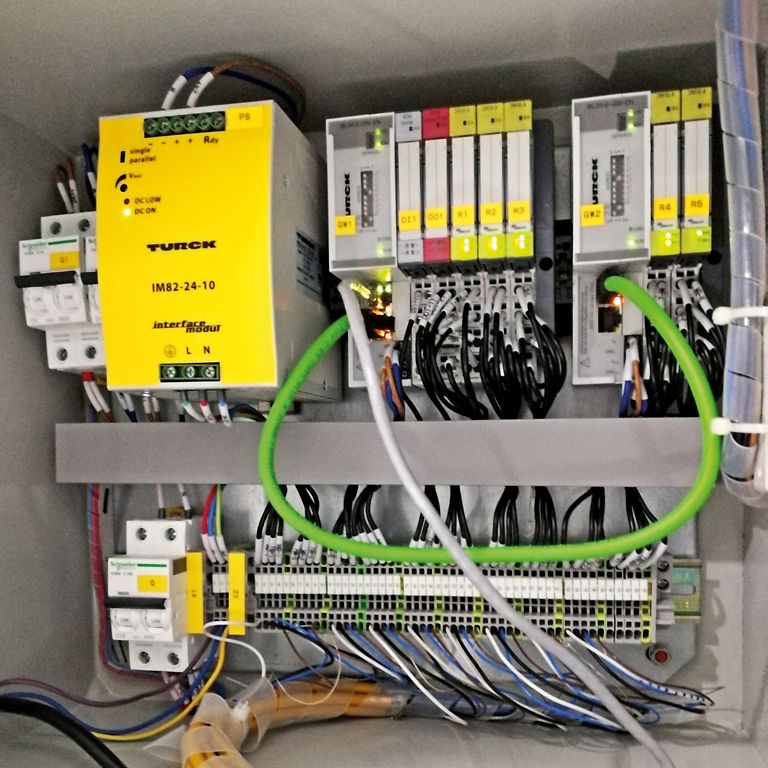

TURCK's BL20 gateway fits well into the clean and tidy production environment. It forwards the data collected by the RFID and I/O modules in the field to the higher-level controller. The RFID tags are attached to the top of each wafer carrier. RFID read/write heads installed on the top of the wafer racks detect the carriers fully automatically and thus ensure their reliable identification during loading and unloading by the AGV.

"The modular design of TURCK's BL20 solution, which can be equipped with other I/O modules in addition to RFID modules, allows sensors and LED displays to interact with the MES via the same gateway. This reduces the effort required for field wiring," explains Project Manager Tao Zhang Yitao . "If a new read/write head is added, only the RFID module and the base plate need to be added, which significantly reduces hardware costs and design effort."

LED displays provide clear information about the operating status of the read/write head and RFID module at all times. The long reading distance of the read/write head gives the robot arm enough space to pick up and place the carrier. The epoxy resin carrier housing in protection class IP68 does not impair the reading process, nor does contamination on the surface. In addition, the tag can be reused, which is ideal in closed-loop applications. Further advantages also impressed Tao Zhang Yitao : "The pre-assembled cables can be installed quickly and guarantee a secure data transfer. Above all, TURCK's RFID products can be replaced quickly during operation, which significantly reduces downtimes and makes maintenance of the devices quick and easy."

Summary

With the rapid development of Industry 4.0 and IIoT, RFID technology will continue to play an important role in the semiconductor industry. By using TURCK's solution for RFID storage location identification, the user was able to significantly increase storage efficiency and further advance the paperless material and information flow. Not only has the material delivery been accelerated, but also the complete traceability of the material data and thus consistently transparent production has been achieved.

Lin Qiang, Marketing & Product Management Department, Turck (Tianjin) Sensors Co.