Cabinet monitoring brings status data to the IIoT

Optimal assembly and intelligent condition monitoring prevent temperature-related damage in the control cabinet: TURCK's smart IM18-CCM control cabinet monitor transfers status data directly into the IT environment for the first time

Quick read

There are many reasons for excessive heat buildup in control cabinets. Risks caused by poorly arranged equipment or inadequate ventilation can often be minimized during the design phase, but when external factors or device anomalies come into play, targeted condition monitoring is required. For anyone looking to process sensor data via Ethernet in the IIoT, TURCK's IM18-CCM cabinet monitoring unit offers a smart solution.

Increasingly powerful devices in smaller spaces are evidence of technical progress. For the control cabinet, the compact design of modern devices means either a smaller external dimension or a higher number of electronic components fit into it. But every innovation has its downside. In this case, as the technology continues to be miniaturized, the downside is having to keep in mind possible side effects such as heat development. In control cabinets in particular, increased or irregular temperature conditions can lead to loss of performance or even failure of individual devices. In addition to the appropriate device arrangement, smart solutions for condition monitoring are all the more important – such as the IM18-CCM, TURCK's compact climate monitor and door monitor, which brings condition monitoring via Ethernet into the IT world.

Take care of electronic "sensitive" items

With a higher device or energy density in the control cabinet, the power loss inevitably increases. This refers to the part of the absorbed current that is not emitted in a process-relevant manner, but rather in the form of heat for electronic devices. If the components of a control cabinet are arranged in such a way that hotspots (heat pockets) can form or cool air can hardly flow, there are several risks: precise measuring instruments may become imprecise, components have a shorter service life or, in the worst case scenario, fail permanently. Complex systems such as control systems are particularly susceptible to heat. Most PLCs have a maximum operating ambient temperature of 55 °C. This is just 15 °C above the "feel-good climate" of many control cabinets.

Detect anomalies before it is too late

It is possible to reduce heat-induced risks to a certain extent at the point when the control cabinet is assembled. Combining devices in blocks of a moderate size, preventing air barriers caused by poorly routed cables or cable ducts, and installing heat-sensitive components as low down as possible — all strategies that create favorable conditions for users. However, even if the topology is optimal and there is an air-conditioning system to provide ventilation, it is still a good idea to continuously monitor the climatic conditions in the control cabinet electronically. This allows maintenance personnel to detect anomalies at an early stage and prevent malfunctions — especially if devices are located in control cabinets that are further away, such as in outdoor areas where weather creates an external factor.

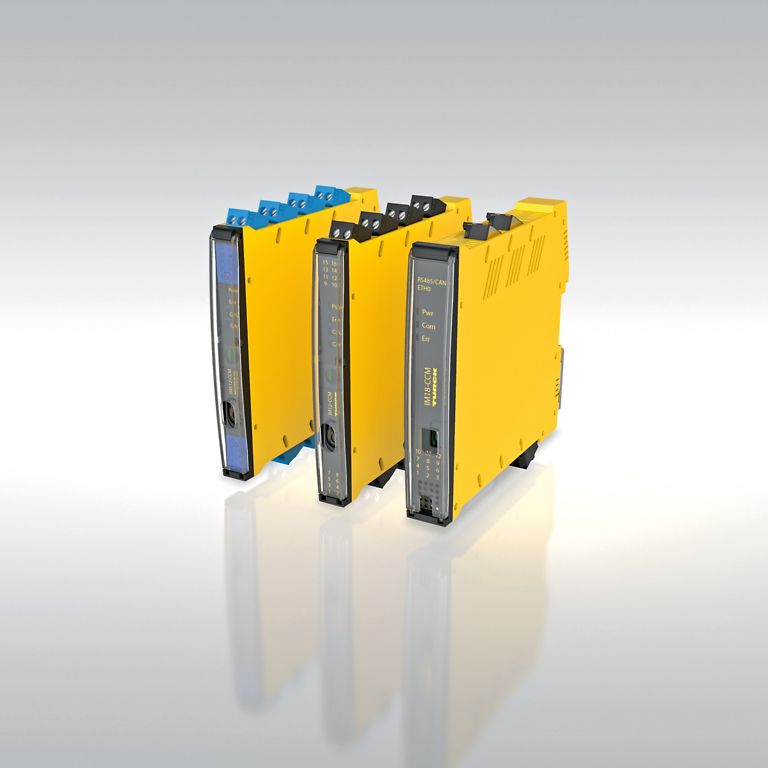

Three-in-one monitoring on the DIN rail

In order to provide a condition -monitoring solution that can easily be upgraded, a few years back TURCK added the IM12-CCM and IMX12-CCM (with Ex approval) control cabinet monitors to its range. These compact devices are mounted on the DIN rail and feature three sensors that monitor temperature, humidity and door distance. The IM(X)12 uses configurable limit value generation to send a signal at the precise moment when defined values are exceeded or undershot. What this actually means is: a device is overheating, moisture is forming in the control cabinet, or the door has not been closed properly.

The IM12-CCM has an internal data logger with time stamp and stores data for up to two years. This allows users to detect gradual changes over long periods of time and to eliminate the cause. Two control cabinet monitors are operated in master-slave mode via an interface in order to monitor the door lock and the other limit values simultaneously at two points in the control cabinet. The master processes the data from the slave and sends a signal to the controller. As standard, the IM12-CCM has two switching contacts and an IO-Link interface. In Quick- Teach mode, the user can easily set the limits on site. Alternatively, parameterization via IO-Link or an FDT framework such as PACTware is possible.

Companies should not monitor the door status purely in terms of temperature and humidity. In particular in relation to "critical infrastructures" (CRITIS) such as electricity and water supply, digital systems must be reliably and verifiably protected against unauthorized access. This is provided for in the German IT Security Act. TURCK's CCM devices score well here with their secure control functions. The devices make every control cabinet suitable for use in critical infrastructures without any significant outlay.

Next steps: connecting the factory level and the IT world

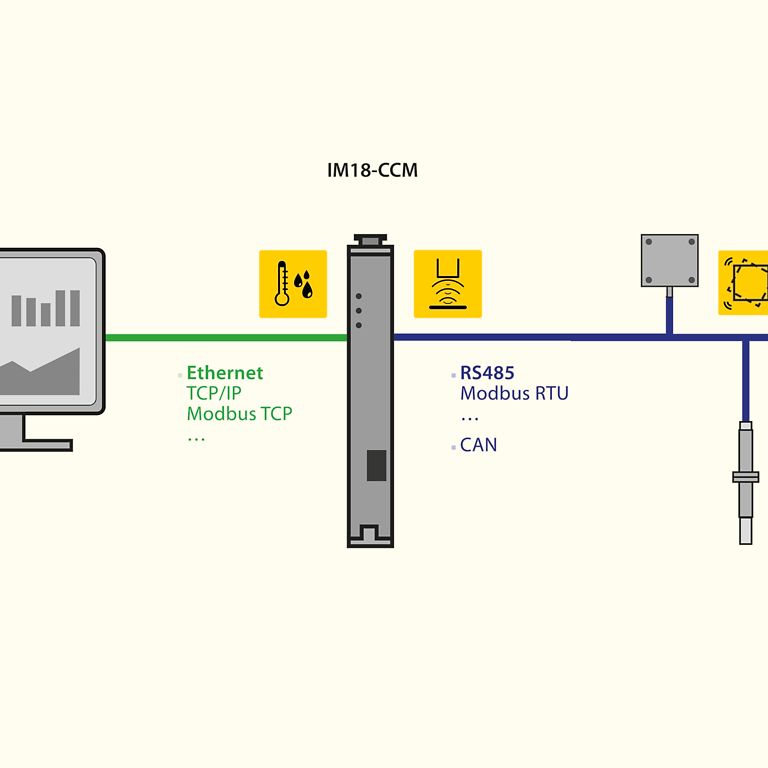

With the IM18-CCM, TURCK is now taking the next step in order to be able to display the status monitoring of control cabinets not only on site, but also to transfer the data to the IT world. The 18 mm slim device supplies the measured values of the sensors to higher-level systems via its Ethernet interface. In theory, this path leads to the cloud, which also enables maintenance personnel to access up-to-date climate data at any time via a mobile end device. This gradually removes the boundary between the operational level and the IT infrastructure. This means that users can analyze factory level data from their desktop.

However, plant engineering contractors and users do not only have access to extended options in terms of data output. There is also more room to maneuver when collecting measured values: external devices such as vibration sensors can be connected to the IM18-CCM via RS485 (Modbus RTU or CAN) in addition to the three installed sensors if required. For an ideal temperature image of a control cabinet, for example, several temperature sensors could be distributed so efficiently to different positions that no further control cabinet guards would be required. The data from three temperature sensors is often sufficient to obtain an accurate overall impression, even in large cabinets.

Freedom for individual applications

Condition monitoring tasks are as individual as the software solutions of many plant engineering contractors or users. Therefore, the IM18-CCM enables the installation of customer-specific applications on its open Linux platform. This allows programmers to feed certain routines into the device, for example to detect a dew point or to take into account natural temperature increases at the beginning of the summer months. Some users may also want to upload their own cloud connector – trends are then visualized or an alarm is sent in the higher-level system.

Outlook: more interfaces, more storage space

Temperature, humidity, and also the safety of control cabinets are factors that play an important role in every system concept. With the right device layout and clever ventilation, designers create the basis for high availability of the electronic components. In addition, these compact and easy-to-use condition monitoring tools in the form of control cabinet monitors are available in order to be informed about critical measurements at all times.

Following the proven devices of the IM12 product series, TURCK has now bridged the gap to the IIoT and also takes into account the freedom to create tailor-made customer solutions. Anyone who wants more interface diversity will be able to access a second device version later this year. This offers an additional Ethernet input as well as universal I/Os, a USB host and additional storage space.

Autor | Klaus Ebinger is Business Development Manager at TURCK