Challenge

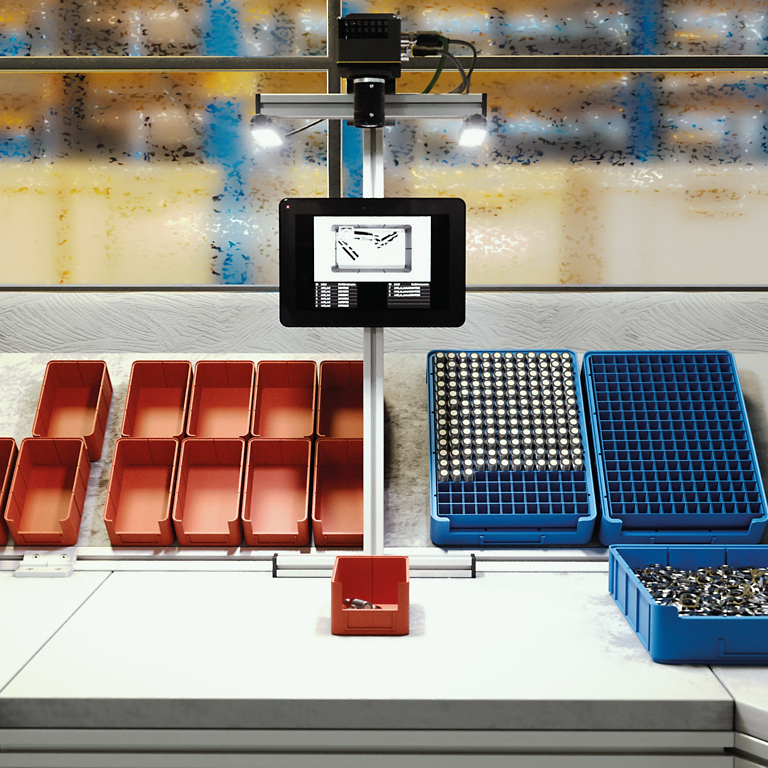

During final assembly at manual workplaces, numerous inspection positions on products often have to be checked. At each position, different statuses can be correct, such as the presence or correct positioning of components. If costly rework and scrappage are to be minimized, the correct placement must be checked automatically during production. It is essential that the complexity of the inspection task does not determine the complexity of commissioning the quality control process.

Solution

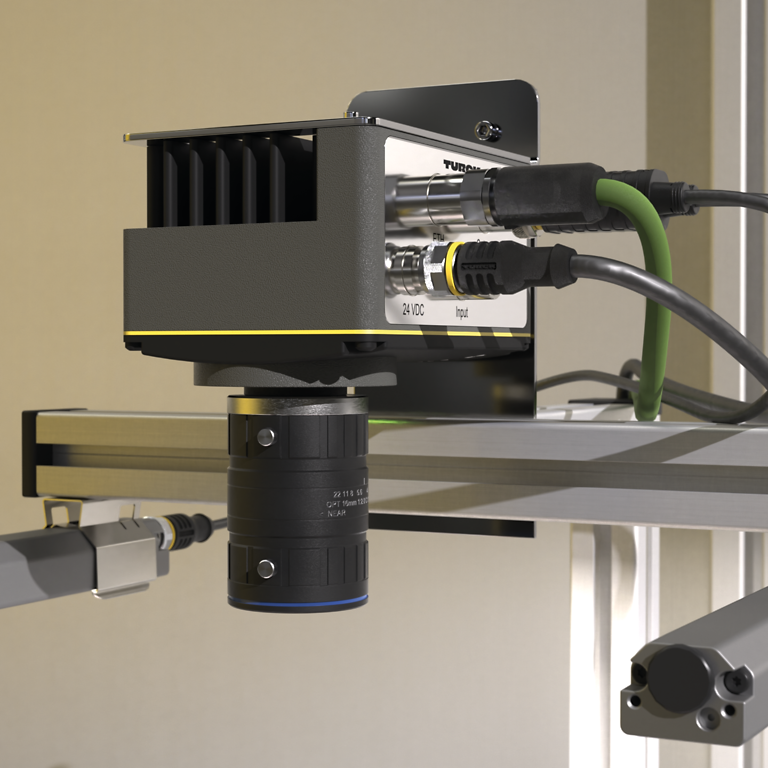

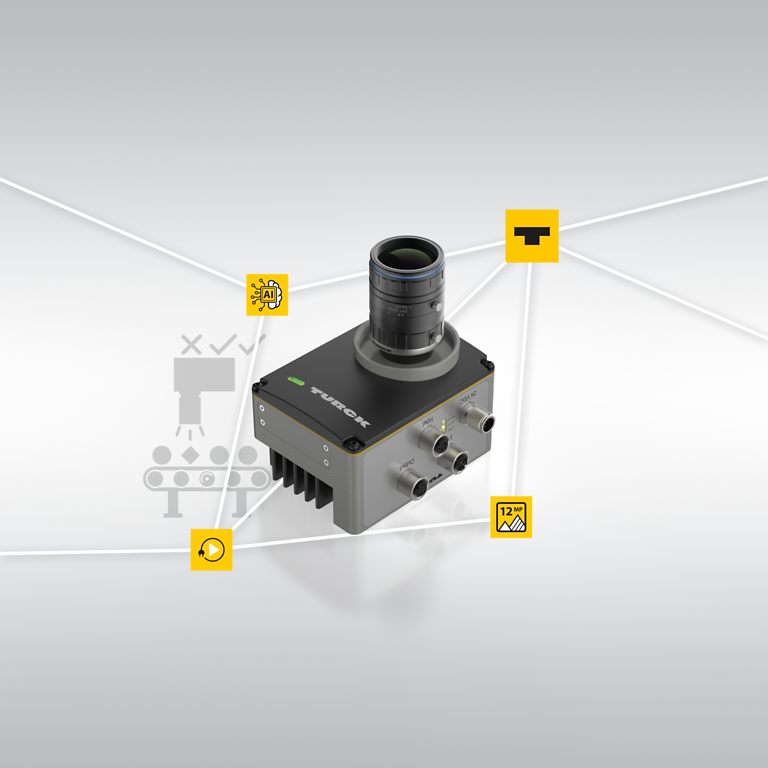

The Difference Check with TURCK Intelligent Vision (TIV) enables teaching-in of objects with several test regions (ROIs). The neural network of the TIV is trained by teaching at least ten images classified as good (OK) and at least ten "incorrect" (NOK) images. The rules behind this are determined by the camera itself. It detects deviations in the test regions and outputs the result via a PLC interface. An image is considered OK if all test regions are correct; otherwise, it is considered NOK. A constant background is essential, as this is also taught in and contributes to object detection. The camera evaluates each test region individually and uses this to determine the overall result. If an issue is identified with a test region, a NOK signal is output that, for example, activates a tower light or triggers the ejection of the product. The personnel are visually informed and can react accordingly.