Challenge

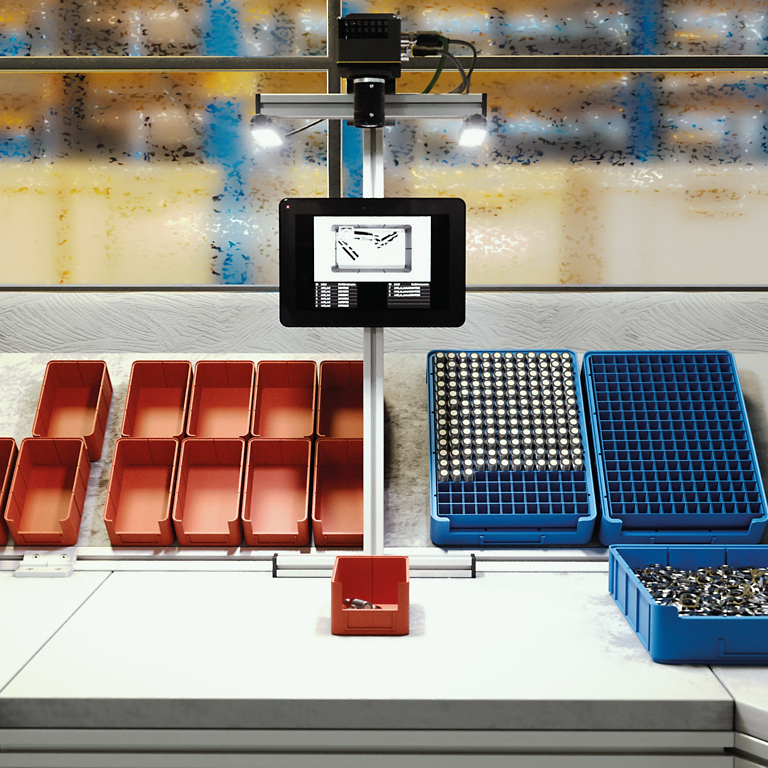

In picking and packing processes, known as kitting, employees assemble sets from various components. Human error can sometimes lead to sets being assembled incorrectly. This causes frustration and damage to the company's image, as well as high costs for resending missing parts. Fully automated processes are not cost-effective in many applications due to low quantities or the necessary flexibility. A camera system is therefore needed that checks and approves the set in the shortest possible time.

Solution

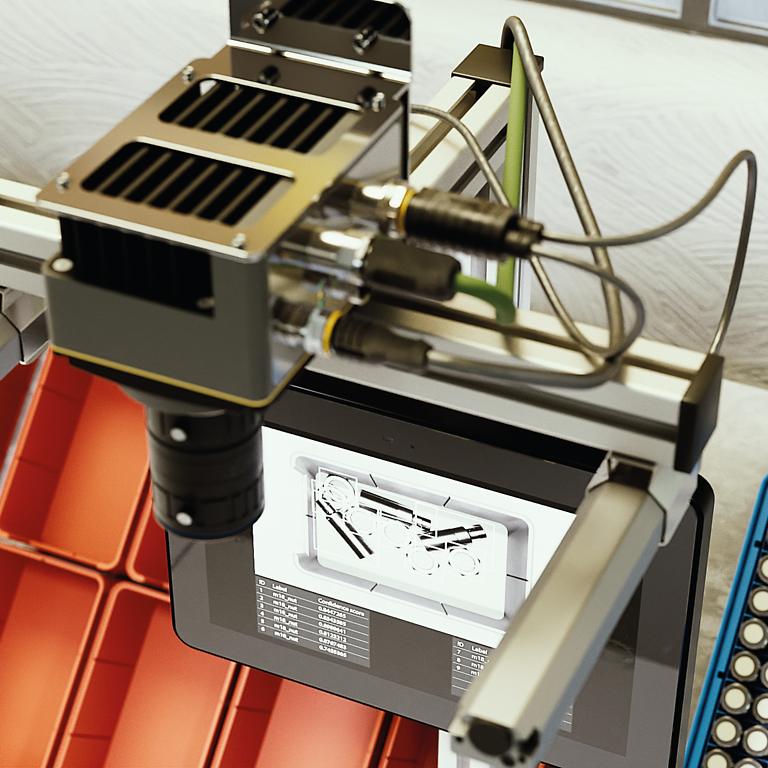

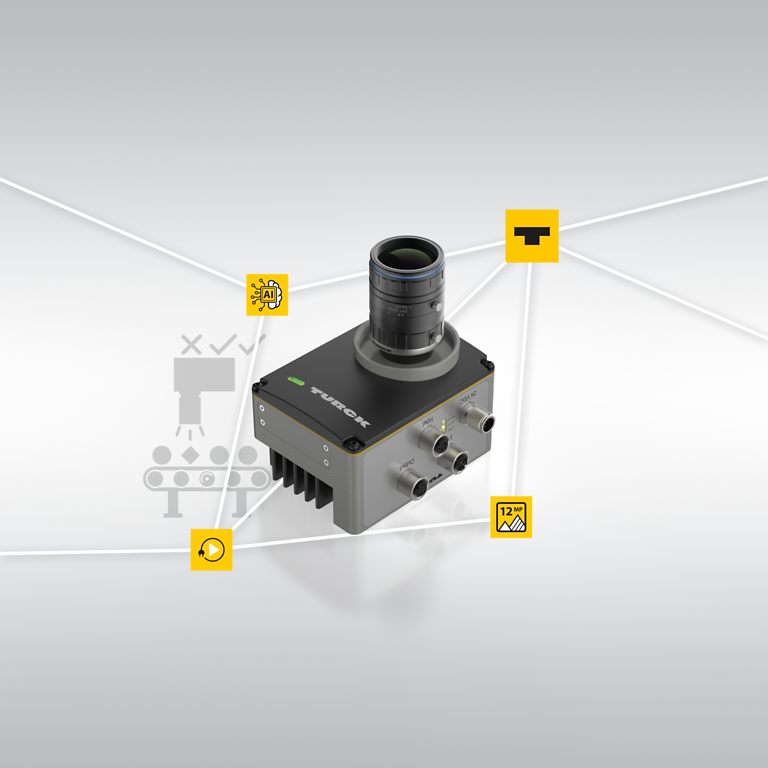

The TURCK Intelligent Vision (TIV) AI camera system is trained using a set of training images. There is no need for complex rule definitions. The camera then reliably recognizes trained items and checks whether the combination of objects corresponds to the defined set. The system reliably recognizes even the smallest differences in the millimeter range or very similar objects such as washers of different sizes, regardless of the arrangement of the components. Various correct configurations can also be trained. For example, employees can train two sets for different sizes when assembling sensor kits. This prevents an M18 sensor with mounting accessories for an M12 sensor from being delivered. The camera transmits the result of the check, OK or NOK, via a classic digital output to the PLC, other systems or displays and other visualization devices.