TURCK Intelligent Vision AI camera: flexible quality control and identification in production

See, learn, decide: The AI camera TIV (TURCK Intelligent Vision) brings artificial intelligence directly into logistics and production, making inspection processes more flexible, faster, and more reliable

Quick read

Modern manufacturing is characterized by dynamism, variety, and ever-increasing quality demands. In this environment, conventional, rule-based image processing systems are increasingly reaching their limits. Each new inspection task requires complex adjustments, and each product variant requires new rules. TURCK Intelligent Vision (TIV) heralds the dawn of a new era. The focus is no longer on programming, but on training, and on image processing that adapts flexibly to changing requirements while combining robustness, precision, and speed.

Innovative technologies with artificial intelligence are rapidly changing industrial production and intralogistics, and image processing is at the forefront of this development. Traditional image processing requires a new instruction for every deviation. Although this is precise, in practice it is often slow and not very scalable. TURCK's AI-based TIV (TURCK Intelligent Vision) camera breaks with this principle. It learns from sample images, independently detects patterns and differences, and transfers what it has learned to new situations. Just a few images are enough to reliably distinguish between good and bad conditions or different classes. Adjustments to products or test characteristics can be integrated at any time through retraining, without the need for expert knowledge. This reduces false alarms and makes tests reliable, even if components differ only minimally in appearance.

A decisive advantage: Process knowledge remains with the user. What is considered "good" or "bad" is defined by the production itself; the camera simply learns the difference. In practice, this dramatically shortens commissioning time. While complex, rule-based inspections often take weeks, a typical completeness check can be set up in no time with TIV. The camera makes decisions based on what the customer shows it. TURCK provides the platform: the process provides the knowledge.

AI tools for practical use: from assembly to packaging

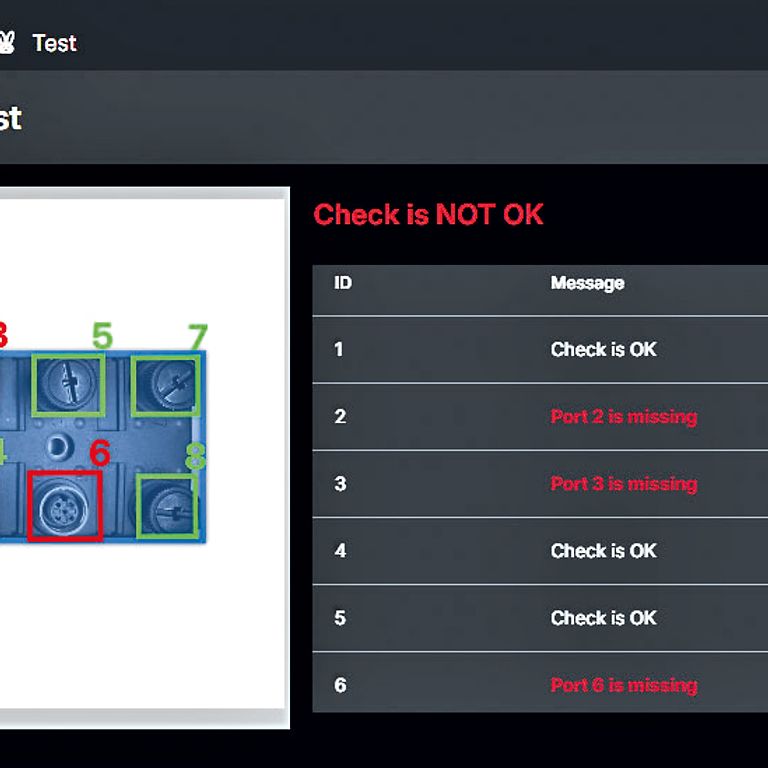

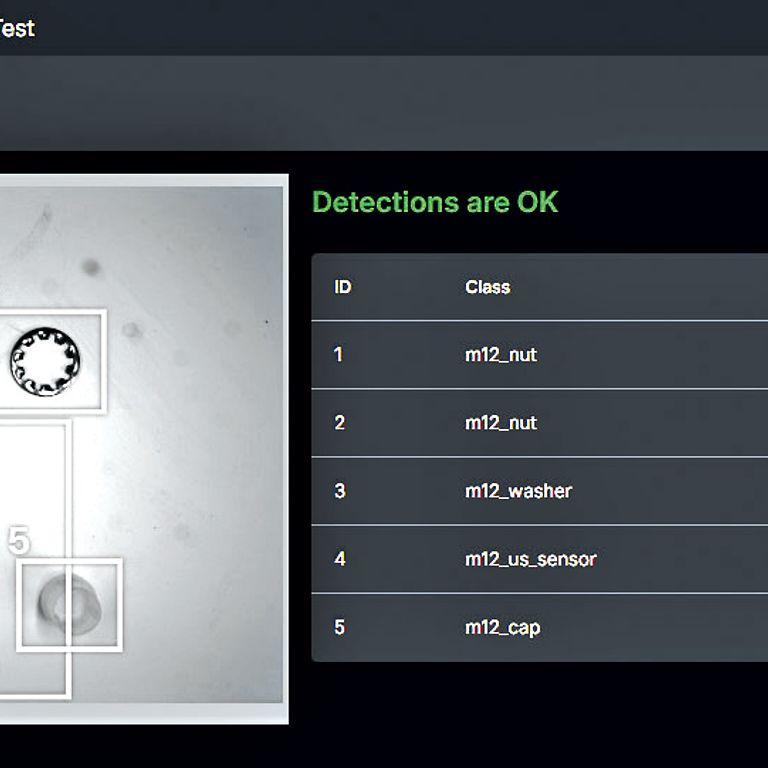

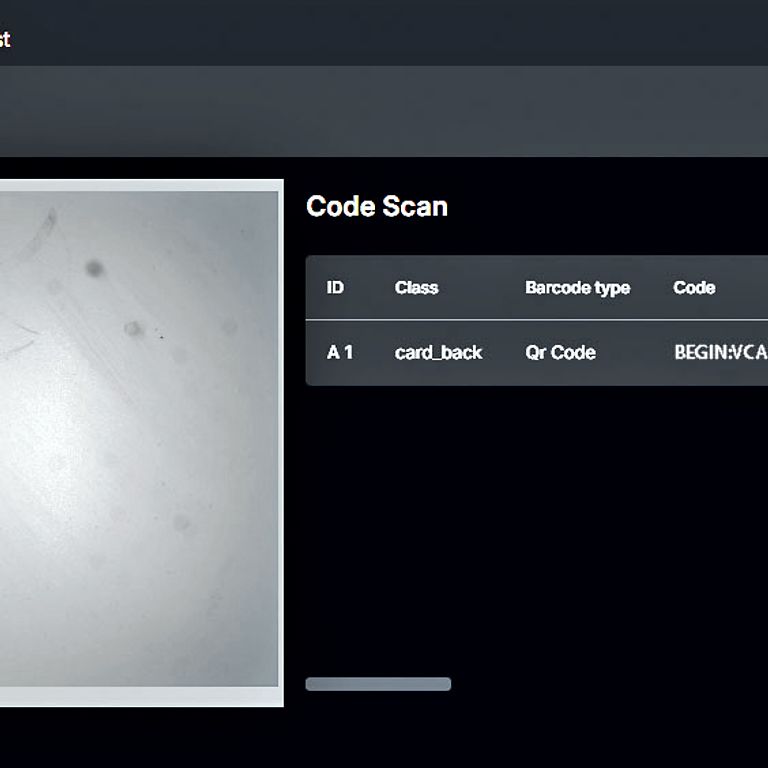

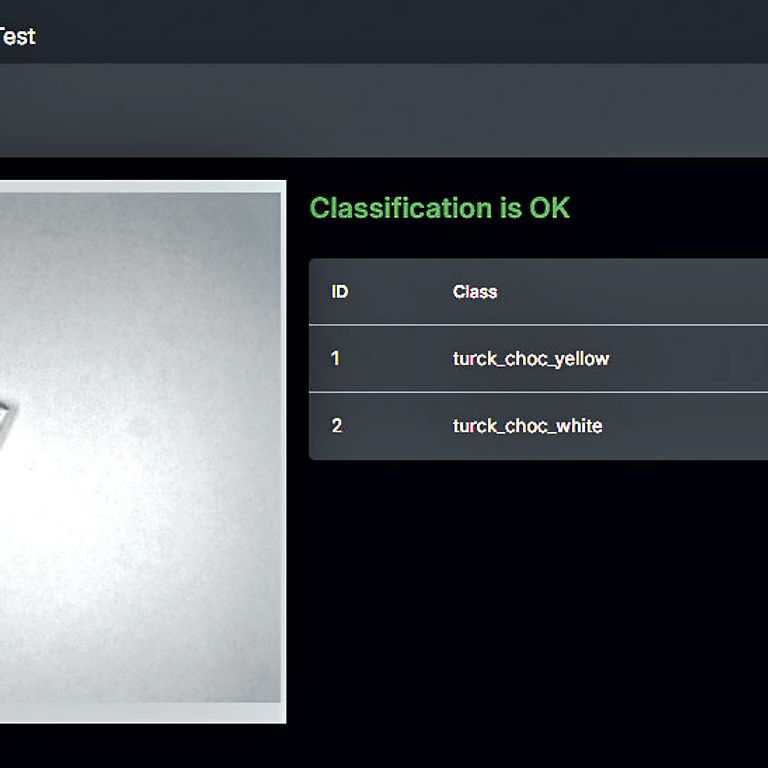

TIV comes with four AI-based vision apps to cover the essential tasks of industrial image processing. The "Code Scan" reads 1D and 2D barcodes, detects type, orientation, and position, and can read specific codes on trained objects. The "Difference Check" performs intelligent target/actual comparisons, detects deviations even with complex or varying objects, and evaluates individual test areas separately. The "Classifier" assigns the entire image to a predefined class; ideal for sorting and classification tasks. And the "Detector" detects and classifies multiple objects simultaneously, evaluates position, orientation, and similarity to the training data, and outputs a confidence score. This produces clear, PLC-compatible results, from simple OK/NOK signals to structured data packets that can be processed immediately. The AI is trained using just a few sample images; changes to products or test characteristics can be integrated at any time through retraining, instead of having to add all conceivable scenarios into rules. The camera continuously learns and remains flexible for future requirements.

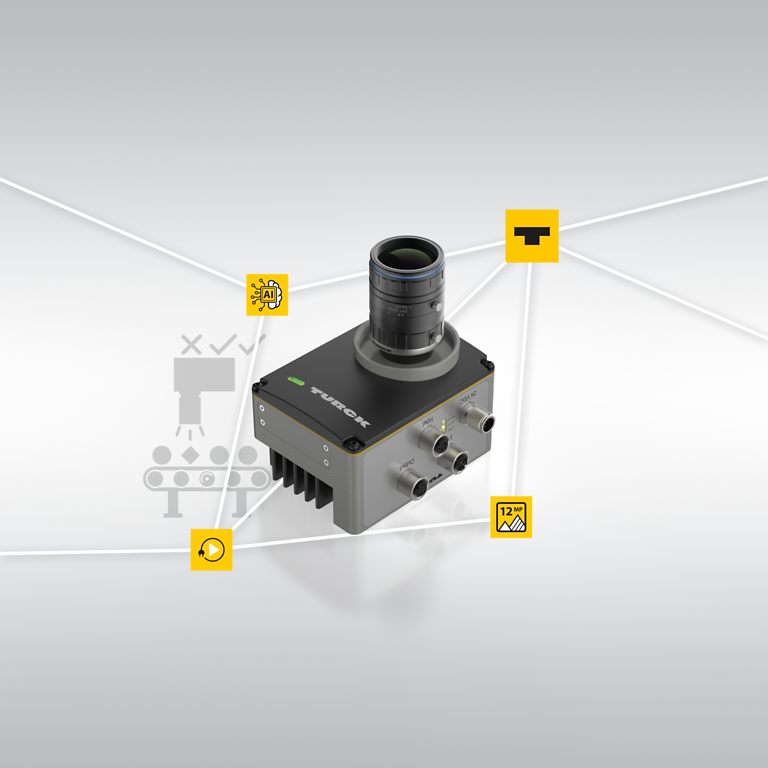

Industrial-grade down to the last detail

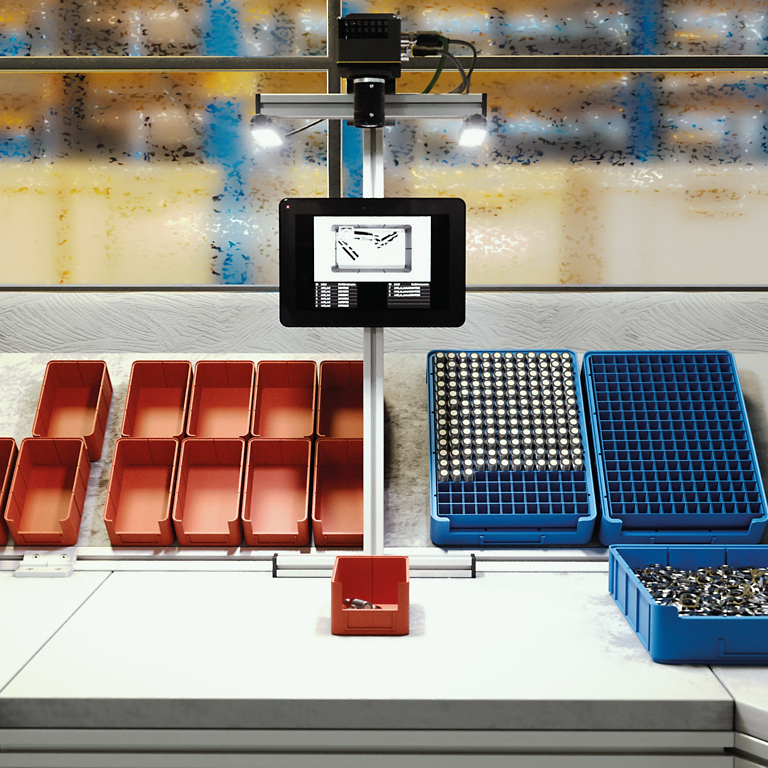

At the core of the TIV is a 12-megapixel global shutter sensor from Sony that enables fast and precise imaging with high depth of field. Image processing runs entirely on the device, including real-time results. AI computing power is provided by a NVIDIA Jetson Nano GPU with 4 GB, on which neural networks are trained and executed directly on the device. Four M12 connectors for power, network, trigger and I/O allow the camera to be flexibly integrated into existing systems. External lighting can be supplied directly with up to 4 A, and the I/Os are push/pull-capable and galvanically isolated. The system operates stand-alone, communicates via PROFINET, Modbus TCP, and EtherNet/IP thanks to Ethernet multiprotocol, displays statuses via LEDs, and stores networks and images internally or on SD/MMC.

All standard lenses can be connected via C-mount; an optional protective tube brings the entire system up to IP67: a real advantage when the camera is located directly on the line. Operation is intuitive via the web browser, and integration into the TURCK Automation Suite (TAS) facilitates device management and integration into digital maintenance and monitoring processes. As a stand-alone solution, the camera does not require any additional control or edge computer. This makes it particularly attractive for applications where space, time, and resources are limited.

From practical use: kitting, assembly, identification, positioning

In order picking, the TIV camera ensures that sets are complete without rigid rules. It detects whether the intended components are present, counts them, and distinguishes between similar parts. This reduces complaints, rework, and rejects, while also speeding up feedback to operators and systems, especially for kits that come in many variants.

During final assembly, the camera checks whether all components are in place, such as caps, screws and washers. Instead of programming all possible error scenarios, it is sufficient to teach the system correct and typical error states. The TIV detects deviations in the millimeter range, regardless of position or arrangement, and immediately reports the result to the PLC or visualization system.

There are also benefits in terms of identification: The camera reads codes where they belong and ignores interfering markings in the environment if they are not among the trained objects. In addition, the Classifier assigns product variants, while the Detector provides coordinates and quantities, for example, to automatically separate or refill parts.

Customer focus instead of catalog goods

If the standard functions of the TIV camera are not sufficient, TURCK will work with the user to develop tailor-made solutions for their application. The spectrum ranges from customer-specific trained AI netwokrs and additional test logic, specially defined data formats and interfaces (e.g. PLC telegrams, MES/ERP hooks) to supplementary apps for special testing tasks and process steps. Piloting and fine-tuning take place directly on the line: TURCK combines domain knowledge and application experience, adapts models through retraining, and ensures robust implementation under real environmental conditions (IP67, changing lighting, cycle times). Integration into existing control and IT landscapes is seamless: from PLC control via TAS (Desktop/Cloud) to the documentation of test and traceability data. This means that a powerful AI camera can be turned into a ready-to-use, individually tailored complete solution as required.

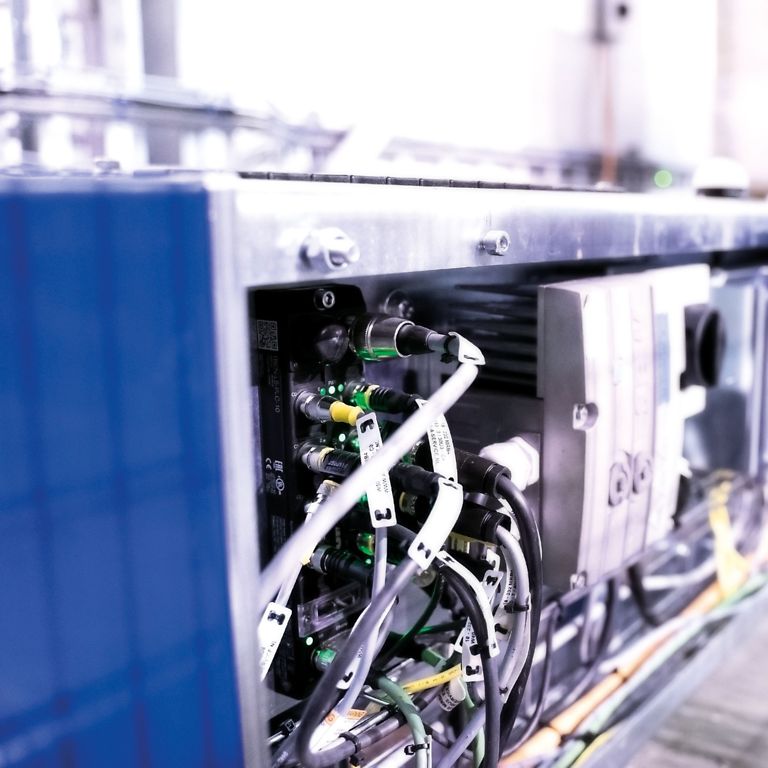

Seamless integration

The TIV camera integrates seamlessly into existing OT/IT structures. M12 connectivity ensures robust connections, trigger signals and indications are routed directly to the line, and lighting is powered directly. As a multiprotocol device, the camera supports the Ethernet protocols PROFINET, Modbus TCP and EtherNet /IP for exchanging data with the control level. Configuration and operation are carried out via the integrated web server or the TURCK Automation Suite (TAS); separate camera software and complex client installations are not required.

Another advantage is the on- premise mode of operation. TIV does not require a cloud connection, which complies with security guidelines and production stability, as users can also store image data on their own FTP servers. Software updates continuously expand the range of functions without hidden license costs. And because data sets and neural networks are transferable, successful setups can be quickly rolled out to additional cameras.

Cost-effectiveness designed into the application

When learning curves and commissioning times are short, image processing pays off faster. This is another area where TURCK's AI camera shows its worth: training instead of programming, stand-alone operation instead of additional edge computers, web setup instead of specialized software. Internal benchmarks show that many standard tasks can be implemented without external integrators; especially where skilled personnel are in short supply and changes are frequent.

Added to this is the investment security of an industry-grade platform: robust metal construction, passive cooling, expandable memory, regular security-related updates. If you start small, with one workstation, for example, you can scale up to additional stations without changing the concept. The camera remains the same, and the networks grow with the requirements.

Solution instead of individual components

The TIV is more than just a high-performance camera. It is part of a complete system comprising sensors, lighting, connection and power-supply concepts, and even control-system integration. For users, this means fewer interfaces, less integration risk, and a partner who can also provide customer-specific solutions as needed: from customized apps to specialized data packages. This system expertise sets the TIV apart in a market where pure components are no longer enough.

Outlook: The future of image processing is adaptive

TURCK Intelligent Vision not only makes image processing easier, faster, and more robust; it also makes it future-proof. The combination of learning processes, industrial-grade hardware, and sophisticated integration makes TIV the tool of choice when quality must be ensured in production cycles. But this is a fraction of its potential: With the ongoing development of AI algorithms, new generations of sensors, and the increasing networking of production systems, image processing is becoming increasingly autonomous, flexible, and intelligent. TIV is ready for this future and brings artificial intelligence to where it has the greatest impact: directly on the production line.

Experience AI vision live – test TIV now!

Want to know what our intelligent vision solution can really do? Then simply send us some images from your application – our camera experts will analyze your requirements and carry out a free, customized feasibility test with TIV. This will give you a concrete idea of how TIV makes a difference: fast, precise, and reliable.

Raphael Penning is Product Manager for Radar and Ultrasonic Sensors at TURCK