IP67 PLC controls the cold storage facility in a decentralized manner

Asbreuk Service B.V. equipped a Dutch logistics service provider with a modular, fully automated truck loading and unloading system, controlled decentrally by TURCK's robust TBEN-L IP67 PLC modules at -25 °C.

Quick read

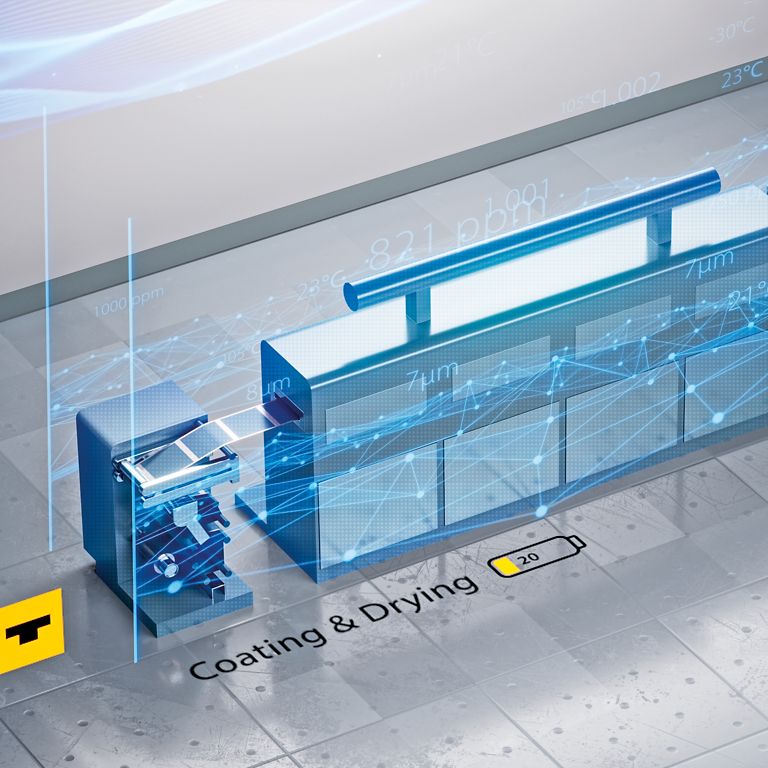

Modularity was the top priority for Asbreuk Service when the Dutch special-purpose machine builder implemented an automated shuttle transport system between the plant of a major food manufacturer and a cold storage facility. The intralogistics system for conveying pallets therefore consists of elements that are controlled decentrally by TURCK's compact TBEN-L5 IP67 PLC modules, even at ambient temperatures of -25 °C. Multiprotocol I/O modules selectively expand the range of available inputs and outputs, while K50 indicator lights from Banner Engineering signal faults along the conveyor line.

Not far from Amsterdam, a renowned frozen French fries producer runs its own shuttle service. Every 30 minutes, trucks operated by the contracted logistics provider travel between the production plant and a massive cold storage facility about one kilometer away. Pallets are loaded fully automatically in a little over two minutes, creating a tightly timed flow of goods that feels like something out of the SimCity computer game, except that drivers are still behind the wheel and trigger the loading sequence.

The partnership between the food manufacturer and its logistics provider is driven by a need for maximum flexibility. A central warehouse with capacity for 40,000 pallets now replaces a far more complex setup in which many different third-party trailers drove directly to the production site. Instead, product allocation happens in the modern XXL cold storage facility and from there shipments go primarily to major restaurant chains. The logistics company does more than run the trucks; it also operates the warehouse and the connected conveying and transport systems, with billing based on the number of pallets handled.

Flexible thanks to decentralized control modules

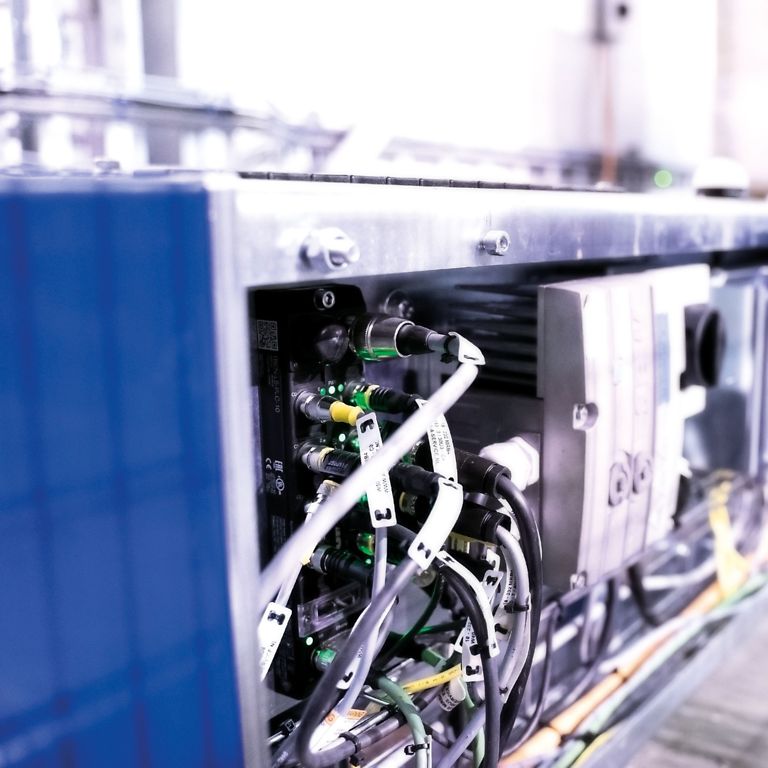

In this short-haul goods transfer, automatic loading and unloading is a key process. Family-owned company Asbreuk Service from the Enschede area was responsible for selecting the right technology as well as planning and implementation. The special-purpose machine builder drew on its many years of experience with projects in the beverage industry. There, for example, large breweries load the entire volume of products and returnables onto trucks automatically. Key takeaway from these projects: technology should be just as adaptable as the business agreement requires. "If a contract changes and something may need to be expanded or reduced, it is important that a system is modular, like Lego bricks," emphasizes company owner Marco Asbreuk In collaboration with TURCK, his company therefore developed a conveyor system made up of segments in which both frequency inverters and the robust TBEN-L PLC IP67 controllers operate in a decentralized manner.

For Asbreuk, modularity is the only way turnkey projects become economically viable. "This only works if we build standardized elements that are easy to install." As in the most recent collaboration, installation of the new line was completed more quickly this time than dismantling the old centrally controlled system. Over the long term, the modern conveyor elements also retain their value because, if necessary, they can be operated elsewhere or in a different configuration.

"It was important to us that the control system is able to communicate with different bus systems and operate down to at least -30 °C. In that temperature range, there is essentially only one PLC, so choosing TURCK's TBEN-L PLC was the obvious choice."

Marco Asbreuk | Asbreuk Service B.V.

Robust PLC reduces wiring

Next advantage: the decentralized modules require considerably less wiring, resulting in significant cost savings, especially in the deep-freeze area where special cables are required, according to Asbreuk. This is because power is supplied at only four points within the conveyor system. TURCK's IP67 block modules with CODESYS 3 control distribute power among themselves and are also connected via serial interfaces. Once plugged together, the modules detect their neighboring modules and their position in the overall system.

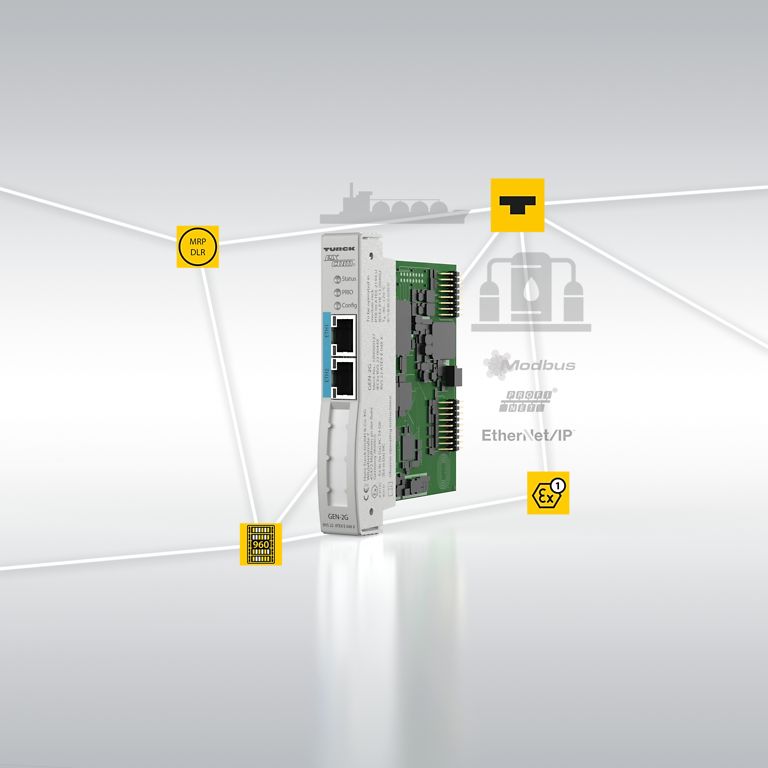

Use in cold storage facilities at temperatures of -25 °C is what led the Dutch company to TURCK's IP67 TBEN-L PLC. "It was important to us that the control system is able to communicate with different bus systems and operate down to at least -30 °C," says Asbreuk. "In that temperature range, there is essentially only one PLC, so choosing TURCK's TBEN-L PLC was the obvious choice."

The compact control system is a key component in the shuttle transport system, which consists of three areas. At the factory there is an Automated Truck Loading System (ATL) including intralogistics that starts directly at the end of the production line. Road transport is then handled by trucks with special trailers whose load beds are equipped with chain conveyors. At the destination, the central warehouse of the logistics partner, drivers start the automatic unloading of the pallets at the push of a button. Meanwhile, the two-lane loading zone at the production site fills up gradually. To ensure the driver always sees the current progress, a smartphone app provides live data from both locations.

Autonomous conveyor system with pallet check

At the French fries producer's plant, Asbreuk Service equipped each of the 32 conveyor modules with its own control system, including chain and roller conveyors as well as a pallet inspection section. Here, laser sensors check whether a pallet is too wide and has therefore been packed incorrectly. First, the result is written to a barcode label and then the system automatically separates the affected pallet. The laser sensors and scanner are connected locally to the respective TURCK PLC. Only when a pallet is rejected does an identical TBEN-L PLC module intervene, acting as a higher-level central control system and connected via CAN bus.

Expansion via multiprotocol I/O devices

To divert individual pallets from the standard conveyor route to a buffer, a conveyor element with three directions is required. Since each direction requires its own RS485 port, a TURCK I/O module at this node expands the range of available interfaces. The ultra-compact TBEN-S-2COM I/O module integrates the serial interfaces directly in the field via PROFINET into the control system, ensuring that RS485 functionality is retained.

Thanks to laser assistance and the interconnected TBEN-L modules, each conveyor section knows when a pallet is to be handed over. If an operator nevertheless needs to intervene in the running process, individual conveyor sections can be controlled separately at two modular and decentralized control cabinets. Possible actions include a controlled stop or routing along an alternative path. Multicolor K50 indicator lights from TURCK's optoelectronics partner Banner Engineering signal, for example, which module has a fault or which conveyor section is currently operating in manual mode.

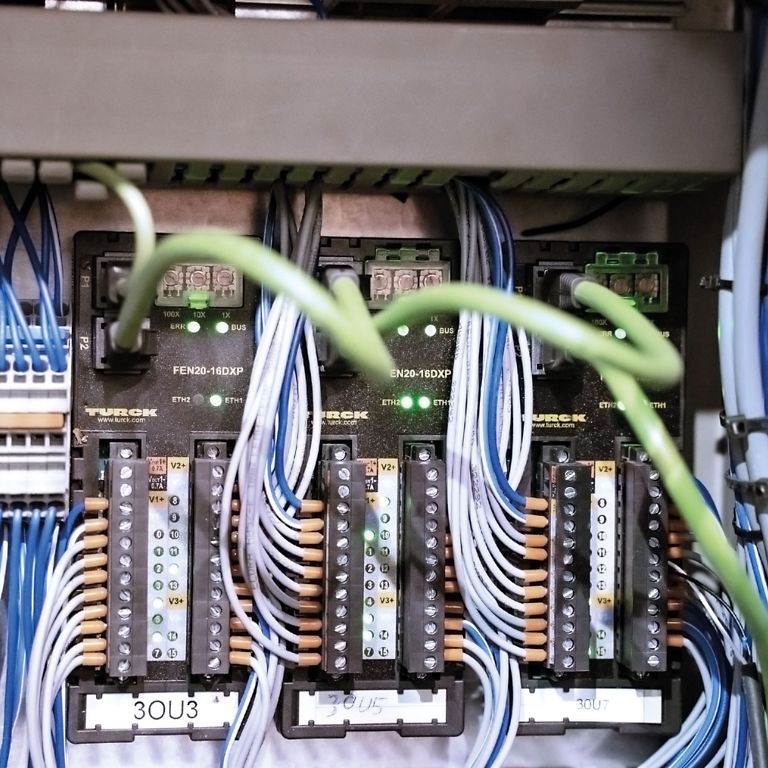

At the operator stations, signaling devices such as pushbuttons require additional inputs and outputs. For that reason, the Dutch team installed three IP20 I/O devices in each cabinet. TURCK's multiprotocol FEN20-16DXP modules make standard switching signals bus-capable quickly and effectively. Use of the FEN20 modules is not limited to the operator stations. In the loading zone (ATL), which the pallets reach via a hydraulic lift, things are still centralized for the time being. The area is controlled by a centrally controlled frequency inverter or a Siemens PLC. In the control cabinet, TURCK's FEN20 provides additional inputs and outputs and communicates with the main control system. However, Asbreuk is not ruling out the possibility that an ATL zone could soon operate in a decentralized manner as well.

The market promises growth

Asbreuk Service is now receiving inquiries for comparable turnkey systems more and more frequently. "The market is growing. There is demand everywhere to move huge volumes over a short distance," says the company owner. In the future, companies will increasingly deliver functions rather than machines, making the specific technology behind a service less important as long as the elements remain flexible and can be used long term.

A modular conveyor concept is ideally suited to these requirements. Asbreuk is already thinking about the next steps: "So far, all we transmit via the truck is the number of pallets. It is possible to transfer larger amounts of data and achieve 100 percent traceability of the goods." There is also growing discussion around the first prototypes of self-driving semi trucks. It stands to reason that autonomous transport could open up completely new opportunities.

Customer | www.asbreukservice.com

Maarten Rambach is a sales specialist at Turck B.V. in the Netherlands