Automation technology enables autonomous asparagus harvesting robot

AvL Motion is breaking new ground with a machine for selective harvesting of white asparagus, packed with high-precision sensors as well as RFID and fieldbus technology from TURCK

Quick read

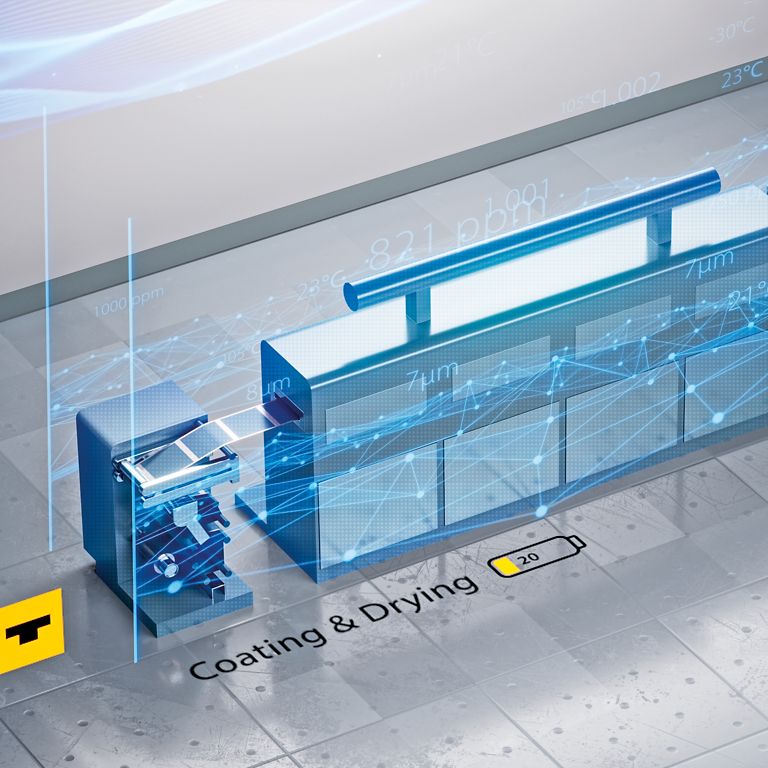

Dutch startup AvL Motion has brought a machine for fully autonomous, selective harvesting of white asparagus to market. While searching for an ultrasonic sensor for height control, the company came across TURCK’s IO-Link-capable RU40U. The collaboration that followed brought additional sensor technology into the vehicle, including miniature inductive proximity switches, precise encoders, LE550 laser sensors from Banner Engineering and the robust Li500-Q25 linear position sensor. To identify the harvesting modules, AvL also uses the TN-Q14 RFID read/write head, while the compact TBEN-S2-4IOL I/O module transmits IO-Link signals to the PLC.

Springtime is asparagus season. Few other seasonal vegetables enjoy greater popularity among restaurant diners and supermarket shoppers. As early as 150 BC, Cato the Elder devoted himself to cultivating this “delicacy for the palate”, and for the Sun King Louis XIV, the delicacy was even meant to appear on the menu at Christmas. Many centuries later, culinary enthusiasm for these prized shoots remains undiminished. In Germany alone, around 122,000 metric tons of asparagus were harvested in 2019 – the country is Europe’s largest producer, with a cultivation area of more than 22,000 hectares.

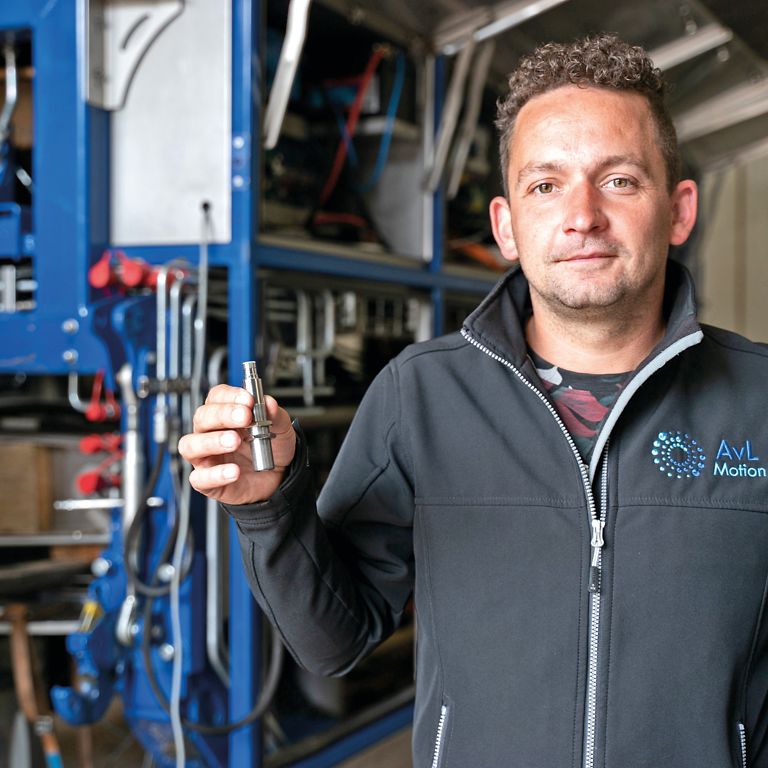

Before the vegetable reaches the plate fresh, however, it usually has to be painstakingly harvested by hand. From March through the end of June, farmers in Germany typically rely on seasonal workers from Eastern and Southern Europe for this task. Recent years have shown, however, that it has become increasingly difficult for farms to find seasonal labor. This prompted Dutch engineering firm AvL Motion to begin developing a mechanical solution for harvesting white asparagus. Around three years later, the startup from North Brabant reports that it has introduced the world’s first fully autonomous, selectively operating harvesting robot. The result is a high-tech prototype with finely tuned sensor and control technology, which customers will be able to deploy as early as the coming season.

Wanted: selective harvesting machine

Company founder Arno van Lankveld grew up on an asparagus farm and therefore knows the major challenges involved in harvesting this popular vegetable: “An asparagus plant produces multiple shoots that can grow in different directions. That complicates the process.” Typically, only spears are cut and pulled once their tips have broken through the soil; the remaining shoots stay in the ridges for the time being to mature under the black-and-white reversible film.

Until now, selecting a market-ready asparagus spear has still required the human eye. Harvesting machines could either cut all shoots at the same height at once or were simply too slow. AvL Motion is now addressing this with a robot that, while moving continuously at speeds of up to 3.6 kilometers per hour, automatically detects asparagus tips, pulls the shortened spears from the soil and transports them away on a conveyor belt. The process requires only one worker: to sort the vegetables into crates on a loading platform, turn the machine at the end of a row via remote control and feed the film covering into the machine’s unwinder. “Farmers can reduce their staffing requirements by 83 percent,” estimates van Lankveld.

“TURCK impressed us with very good quality and fast delivery.”

Arno van Lankveld | Geschäftsführer | AvL Motion

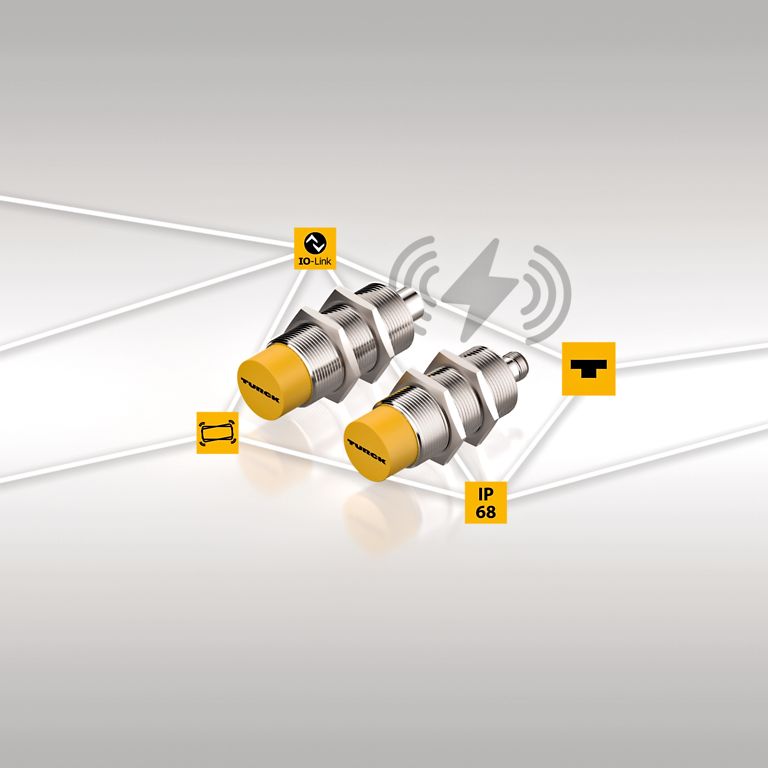

Height control via an IO-Link ultrasonic sensor

To automate such a complex process, in addition to the pioneering spirit of the seven employees, the right technology was essential. When an ultrasonic sensor caused problems in practice, electrical engineer and software developer Jordi Hutjens found an alternative solution in TURCK’s RU40U model. AvL Motion now uses two of the IO-Link ultrasonic sensors to measure the distance between the asparagus bed and the machine’s pneumatically adjustable inner frame. Even with ground conditions that are sometimes dusty or wet from rain, the sensor enables stable height determination, which users can set on an HMI. “TURCK impressed us with very good quality and fast delivery. That’s why we also stayed with the manufacturer for other components,” says AvL Managing Director van Lankveld.

Optical method replaces a trained eye

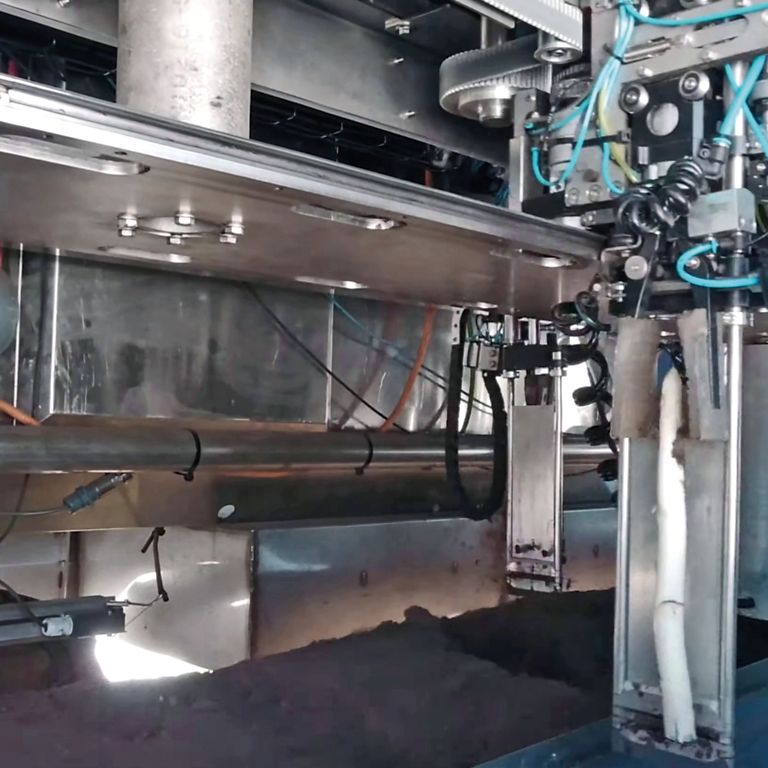

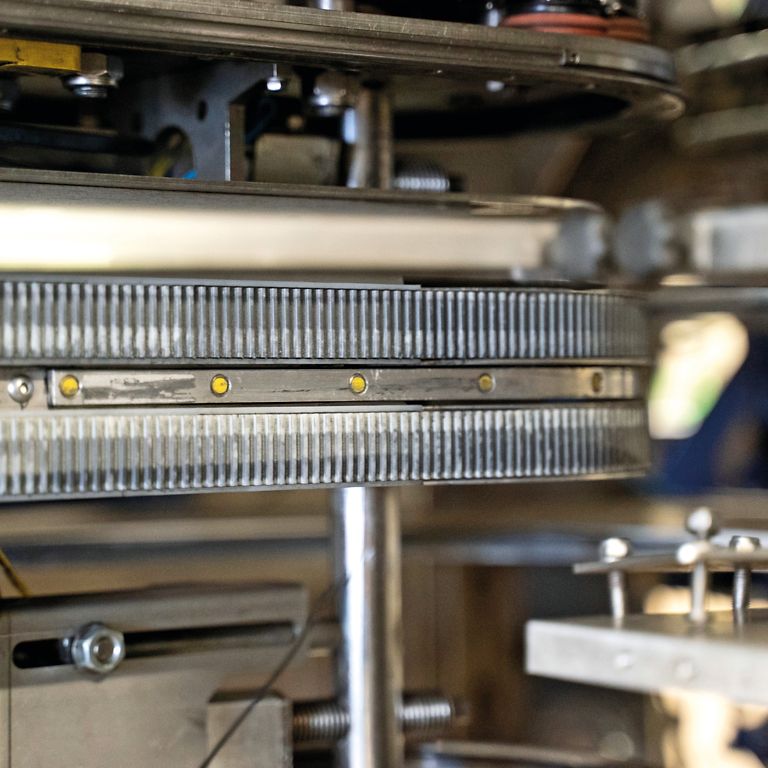

The harvesting process of the AvL Compact S1560 is highly dynamic. Once the machine is positioned and set in motion, it first begins scanning the soil surface. Laser sensors (supplemented by another optical method) provide the main control system with the exact location where an asparagus tip protrudes from the ground. The details remain a closely guarded secret of the inventors; the only requirement is weed-free soil. Meanwhile, inside the robot, a variable number of harvesting modules moves along a rotary path – currently twelve cassettes, each about 25 centimeters tall. They are matched to the machine’s travel speed and handle the entire sequence of spearing, cutting and gripping.

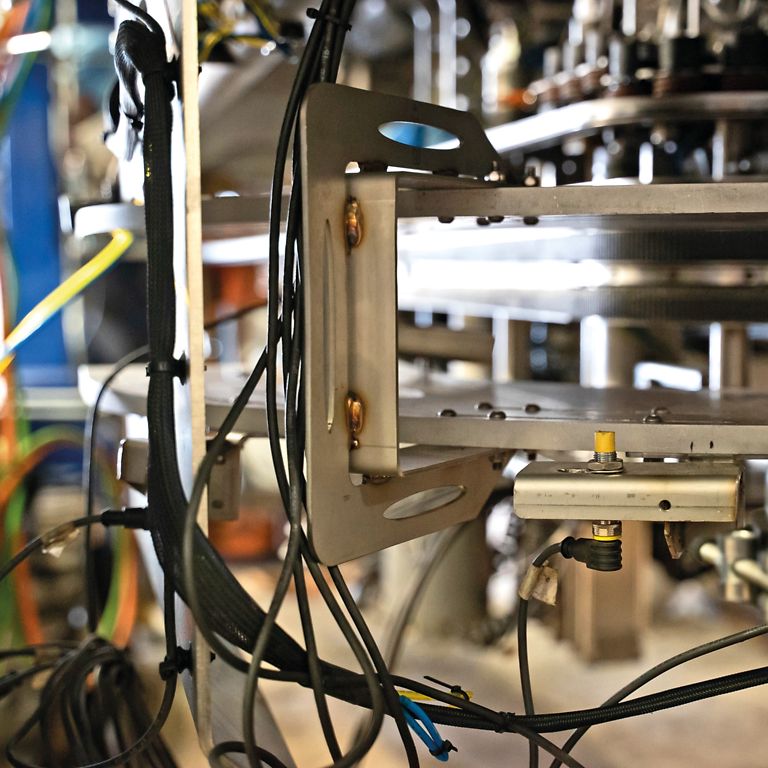

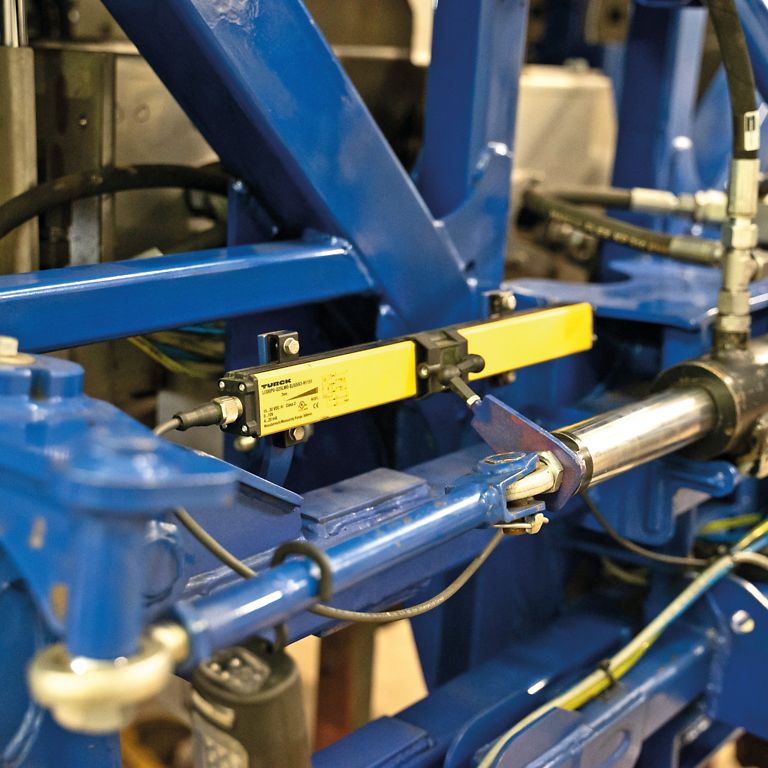

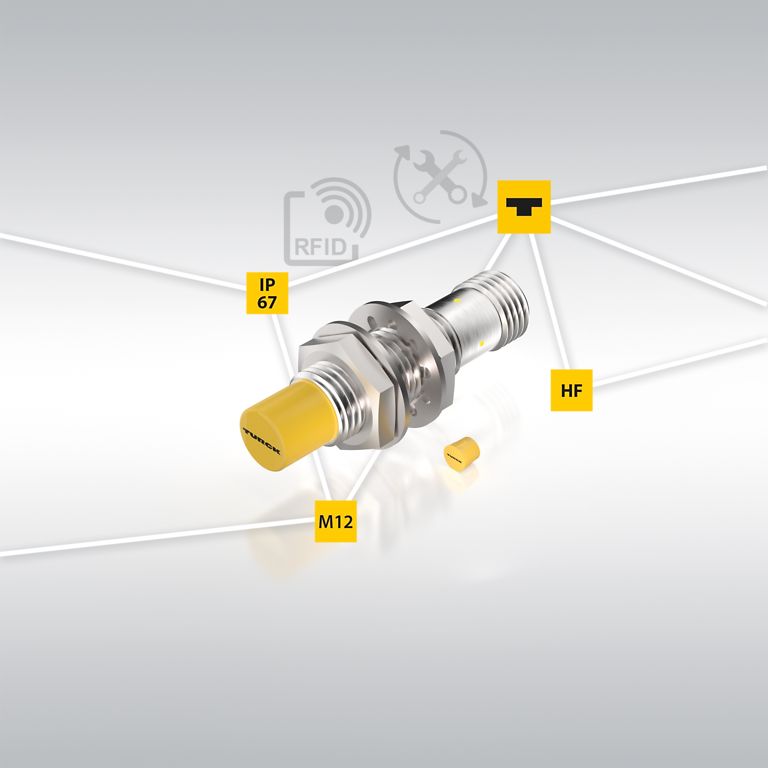

Fine-tuning between target and harvesting module

To fine-tune the harvesting process, the control system requires not only the coordinates of the asparagus spears in question, but also continuous information about the position and movement of the modules. This starts with querying how many cassettes are currently in the buffer – i.e., parked in the home position – and can be sent into rotation when an asparagus shoot is detected. AvL uses the tiny BI3-M08K inductive sensors for this purpose. Precise identification of the harvesting modules is handled via RFID, using the TN-Q14 HF read/write head, which reads the unique code of each cassette.

Position is also determined using encoders. “The encoder rotates along with the buffer area. That allows us to see, for example, that a cassette is located at millimeter 20 or 30,” explains AvL developer Hutjens. When the rotation of a harvesting module is then started, it passes an uprox proximity switch of type NI10U-M12, which triggers the timer for a harvesting cycle in the PLC. Such a multi-layered preparation is necessary to synchronize cassette movement while the machine is operating at full speed.

Because asparagus spears do not grow in neat rows, the harvesting modules can move left and right in addition to their rotary motion. This movement is pneumatic and therefore always delayed by a few tenths of a second. To ensure the cassettes still align precisely, the PLC receives information on the distance between the modules’ start and target positions, measured by LE550 laser sensors from TURCK’s optoelectronics partner, Banner Engineering.

Turning maneuvers via joystick

Operators can influence the speed and hydrostatic steering of the harvesting machine by means of an external control module. Two TURCK encoders measure wheel revolutions, and AvL captures wheel position using inductive linear position measurement. To enable this, the position marker of the LI500-Q25 sensor is coupled to the piston of the steering cylinder. This allows the main control system to calculate the steering angles of both wheels from a single value – and operators can comfortably turn the machine using a joystick. Unlike competing models, farmers do not need to hitch the AvL Compact S1560 to a tractor.

Compact I/O module for fast data exchange

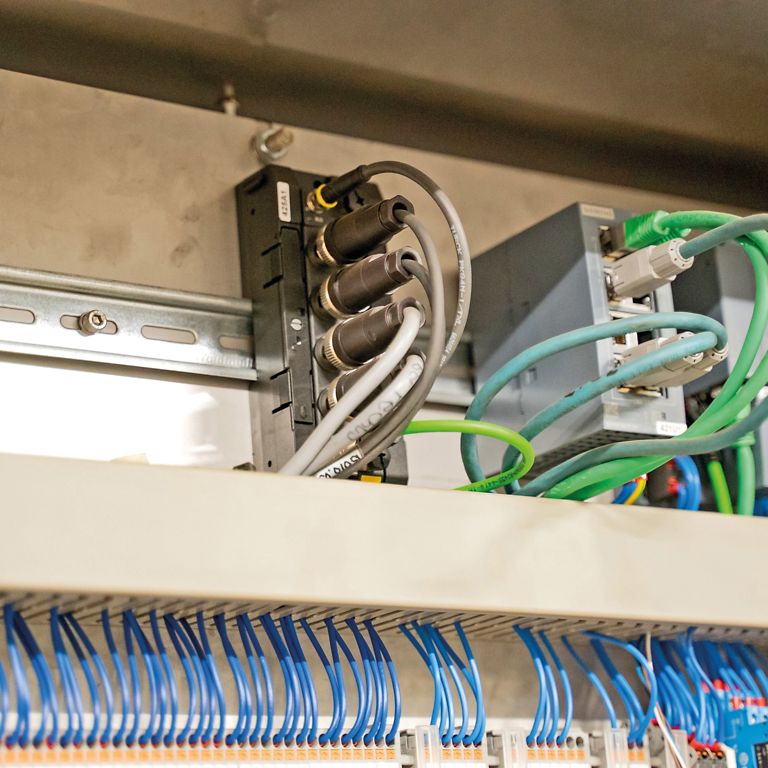

For both the LE550 laser sensors and the RU40U ultrasonic sensors, the AvL engineers opted for IO-Link communication. The interface provides additional information during data exchange and also simplifies sensor parameterization. Using TURCK’s compact TBEN-S2-4IOL I/O module, the IO-Link signals in the control cabinet are forwarded quickly to the PLC. Communication with the control system runs via PROFINET.

Delivery for the start of the season

AvL Motion shows that startups are not confined to only software businesses or the usual digital hotspots. At the same time, the company shares the mindset of many entrepreneurs – from identifying a customer requirement to meeting the pressure to deliver a working final product on time. For AvL, “on time” means: by asparagus season. After months of tinkering, the engineering firm has now delivered its first harvesting machine to Neessen B.V. near Venlo. In the future, says CEO Arno van Lankveld, the robot may eventually operate completely without any human oversight. “For now, we’re simply providing our answer to what asparagus growers urgently need.”

Customer | www.avlmotion.com

Ronald Heijnemans is a sales specialist at Turck B.V. in the Netherlands