Inductive coupler for contactless energy and signal transmission

With contactless energy and data transmission based on inductive coupling, TURCK offers a wear-free solution for high-stress connections with up to 18 W of power

Schnell gelesen

Roboter mit Wechselwerkzeugen oder Rundtakt- tische stellen hohe Anforderungen an die Verbindungstechnik. Verschleißende Kontakte und Steckverbindungen erfordern kurze Wartungsintervalle oder können sogar zum Maschinenstill- stand führen. Damit stellen sie die Verbindungstechnik vor besondere Herausforderungen. TURCKs berührungslose induktive Koppler der NIC-Serie stellen eine verschleißfreie Alternative zu Schleif- ringen oder stark beanspruchten Steckverbindungen dar und übertragen via IO-Link bis zu 16 Schaltsignale und bis zu 18 Watt Leistung.

Inductive coupling is a technology that accompanies us in many areas of everyday life, but often goes unnoticed. It enables the energy transfer between two devices without physical contact and is therefore also referred to as a "contactless connector." Well-known examples are the wireless chargers for smartphones or electric toothbrushes, which draw energy using inductive coupling. In medical technology, inductive coupling is used, for example, for contactless current and signal transmission in medical implants such as pacemakers. These are just a few examples that show how present and versatile the applications of inductive coupling are.

Freedom of movement and free from wear

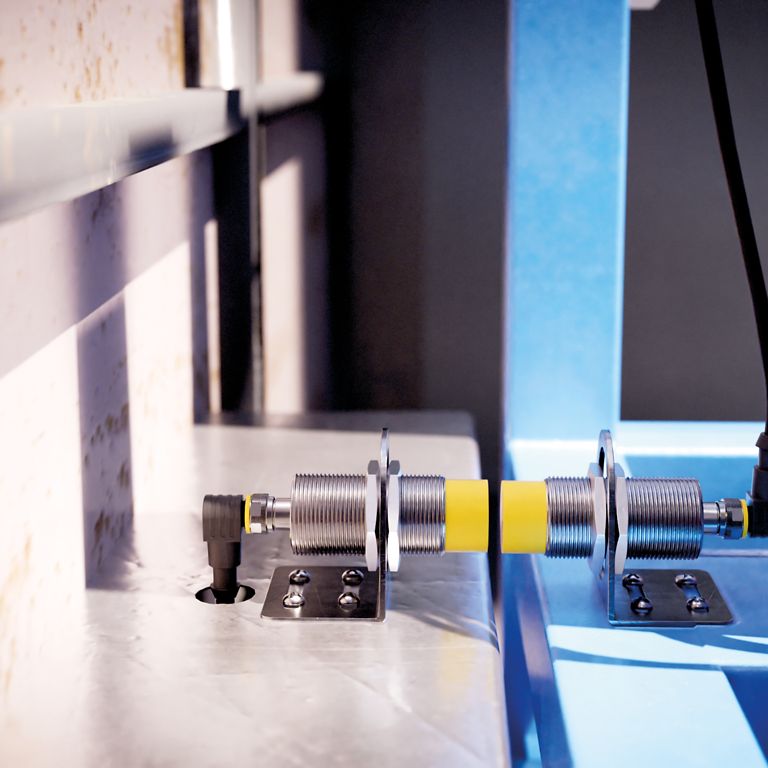

In industrial applications where connections are subject to high loads, such as vibrations or frequent connection and disconnection, not only wear is a major cost factor, but also the associated downtime. Examples of such applications are tool changing systems, mobile workpiece carriers in constant motion or rotary index tables. Another area of application is electric overhead conveyors used in the automotive industry. In this case, inductive couplers not only offer the advantage of being wear-free, but also help to avoid user errors.

Instead of conventional connections, which wear out over time and require regular maintenance, the "contactless connectors," i.e. inductive couplers, enable a smooth and reliable transmission of data and energy without any physical contact between parts. This saves time and money by eliminating expensive repairs or the need to replace worn connections.

Coupler family with high shock resistance

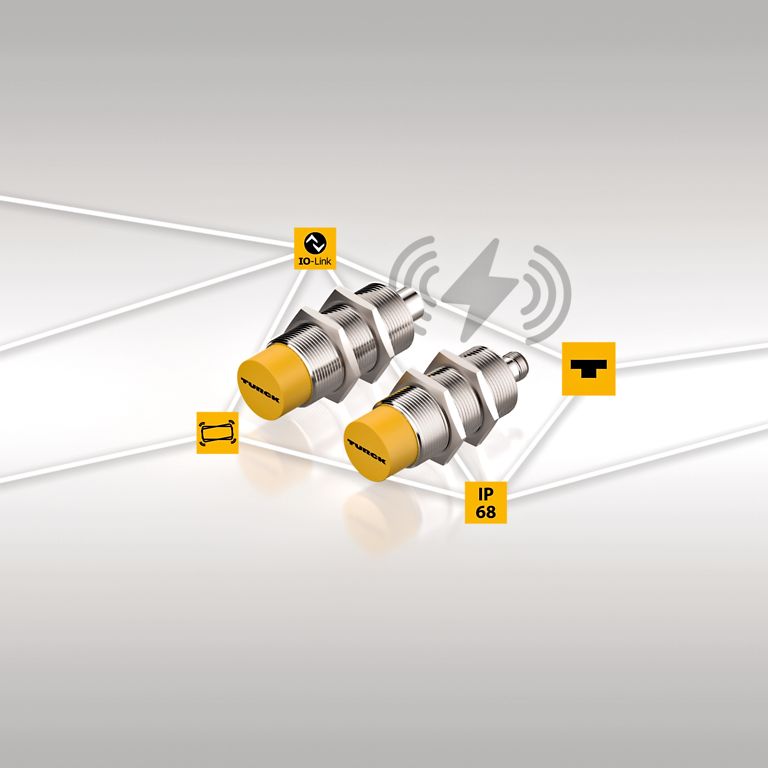

Inductive coupler sets each consist of a primary side (transmitter) on the control side and a secondary side (receiver) on the sensor/ actuator side of the connection. With the newly issued inductive coupler sets of its proven NIC system, TURCK delivers not only performance improvements but also new functions. The NIC couplers operate with a high-frequency alternating field that transmits energy in a frequency range of 100 to 148.5 kHz. At the same time, data is transmitted via a separate radio connection at 2.4 GHz.

The NIC couplers enable the transmission of currents up to 750 milliamps and a power of up to 18 W, even under high shock loads via an air interface of 7 mm. As "wireless IO-Link cables," they are completely wear-free and permanently sealed with IP68 degree of protection. This allows sensors and actuators such as light curtains, position and proximity sensors or even smaller valve clusters to be operated without the need for an additional amplifier on the secondary side. An M12 connector is used to connect the primary side, and the secondary side is equipped with an M12 connector. With their M30 housings, TURCK couplers are among the most compact devices on the market.

Flexibility in signal transmission with IO-Link

The inductive couplers can be connected as easily as a plug-and-socket cable connection. An IO-Link device, often an IO-Link hub, is connected to the secondary side (NICS-EM30-IOL-HK1141) of the coupler system. The primary side (NICP- EM30-IOL-H1141) is positioned opposite the secondary side and connected to an IO-Link master with a standard M12 3-pin connector. This configuration offers the flexibility to transmit up to 16 binary signals and provides a scalable solution for applications where a large number of signals need to be captured and transmitted. It enables bidirectional IO-Link communication in which functions such as parameterization and diagnostic data can be used.

If no IO-Link connection is required, a simple VB2 splitter can be used downstream of the secondary coupler for contactless transmission of two switching signals. For this purpose, the primary side is connected to the controller or a fieldbus device via a four-pin standard M12 connector.

Security through smart third-party object detection

TURCK's innovative dynamic third-party object detection enables not only the identification of larger but also smaller metallic objects between the primary and secondary couplers. The system switches off automatically when such objects are detected in order to avoid possible heating effects. As soon as the obstacle is removed, the system switches itself back on again. This function ensures the safety and integrity of the system and ensures trouble-free operation.

TURCK's inductive couplers transmit the full power of 18 W via an air interface of up to 7 mm. In addition, the devices are insensitive to vibrations and rotation of the primary and secondary sides. If the primary and secondary sides are positioned directly opposite each other at the nominal distance, up to 5 mm of lateral offset are possible. If the application makes a linear assembly of the two coupler parts impossible, the coupler systems can also be mounted at an angle to each other. At a distance of 7 mm, an angle of up to 30° and a lateral offset of 2 mm are possible here.

Fast startup behavior and selective pairing

In many applications with frequently changing connections, the standby time of the secondary side also plays a role. The cycle times that can be run with the connection solution are a central decision criterion, especially for rotary index tables. A fast and stable startup behavior with a response time of 600 milliseconds enables shorter production cycles and thus increased plant productivity. "Dynamic pairing" allows primary sides to be combined with any number of secondary sides and vice versa. This means that even tasks in more complex applications with multiple primary and secondary sides can be solved without any problems. Depending on the application, the coupler itself can also be addressed via IO-Link. In addition to transmitting diagnostic information, this also enables unique " selective pairing," in which a primary side only communicates with selected secondary sides. This prevents errors and downtimes that can be caused by undesired communication between the primary and secondary sides, for example if a workpiece carrier may only be used at a specific workplace. Using " selective pairing" increases process reliability by allowing a tool to be used only on a specific holder or by securing other critical assignments.

Great potential

The further development and optimization of the inductive couplers holds enormous potential for the future of industrial automation and promises more efficient, reliable and advanced solutions for a wide range of production applications. With their robustness and versatility, they could help make decisive progress.

Despite the increasing relevance and flexibility of contactless data and energy transmission, wired connections remain the gold standard in most industrial applications. With its extensive range of connection technology, TURCK offers the right connection solution for almost every application, whether contactless or wired, supplemented by fieldbus and control technology, RFID, sensor technology and more.

Author | Dustin Küpper is Product Manager for Position and Proximity Sensors at TURCK