Präzise Sicherung der Materialzufuhr

TURCKs induktive NIC-Koppler-Sets übertragen kontaktlos Daten und Energie zwischen mobilen Werkstückträgern und Arbeitsstation

Benefits

- Wear-free power supply to the sensors on the workpiece carriers

- Fast connection setup for efficient material supply

- Identification via IO-Link

Challenge

In automotive manufacturing, workpiece carriers transport components between production steps. To optimize material flow, the machine controller must uniquely identify each carrier and precisely record its load. Conventional connection technology can be maintenance-intensive and susceptible to wear. A non-contact, wear-free solution is required to minimize unexpected downtime and maintenance costs.

Solution

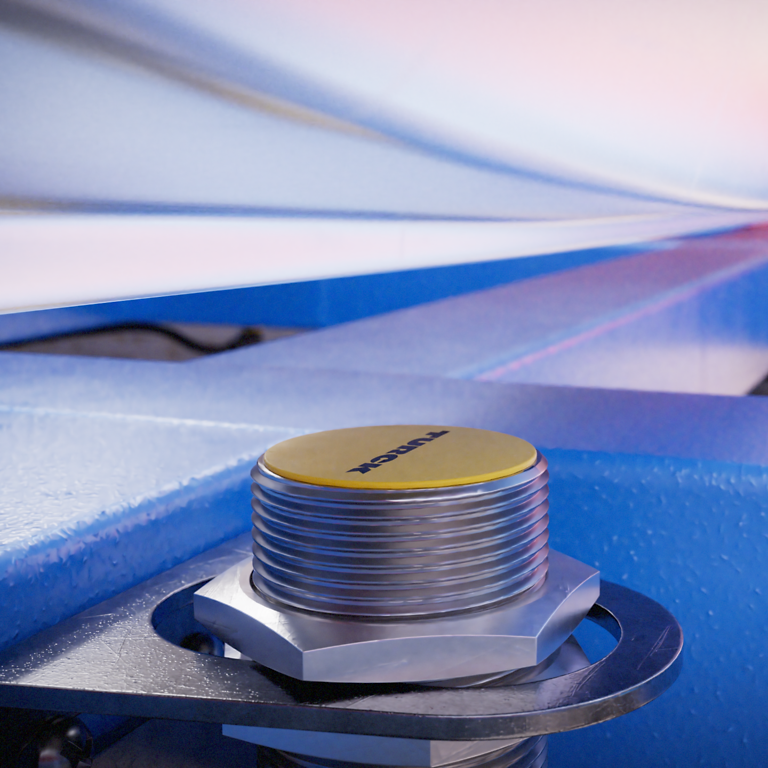

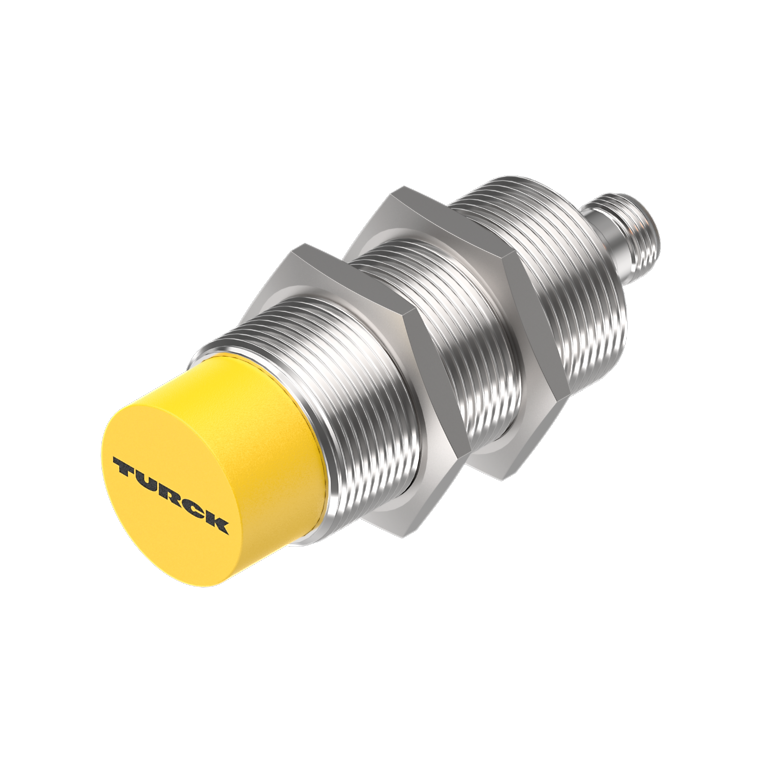

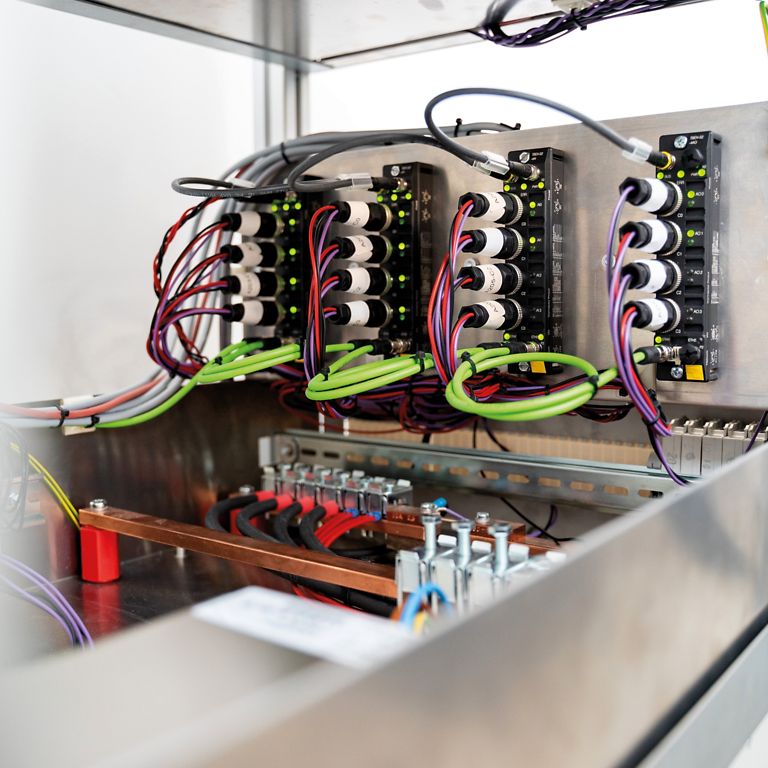

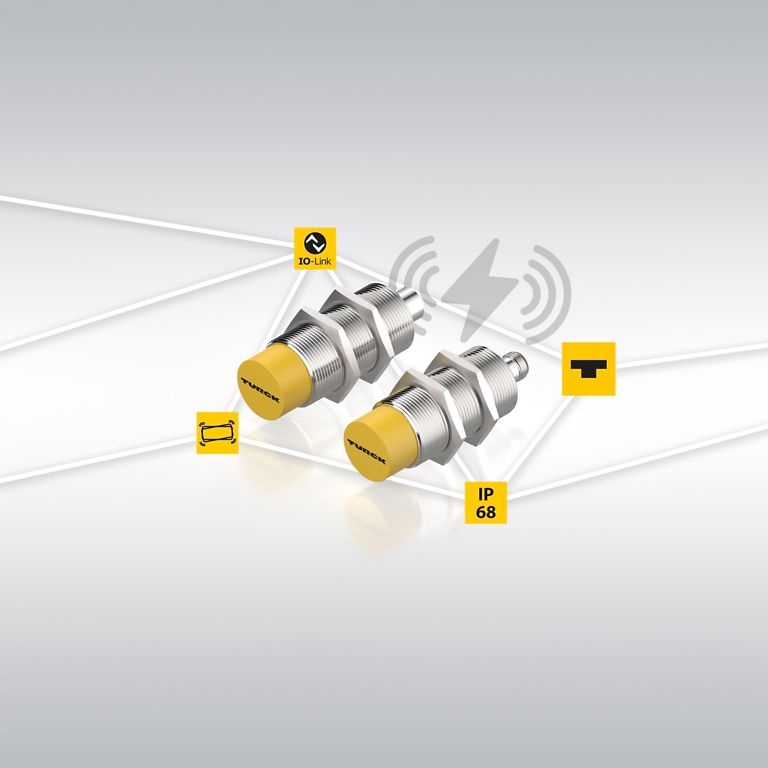

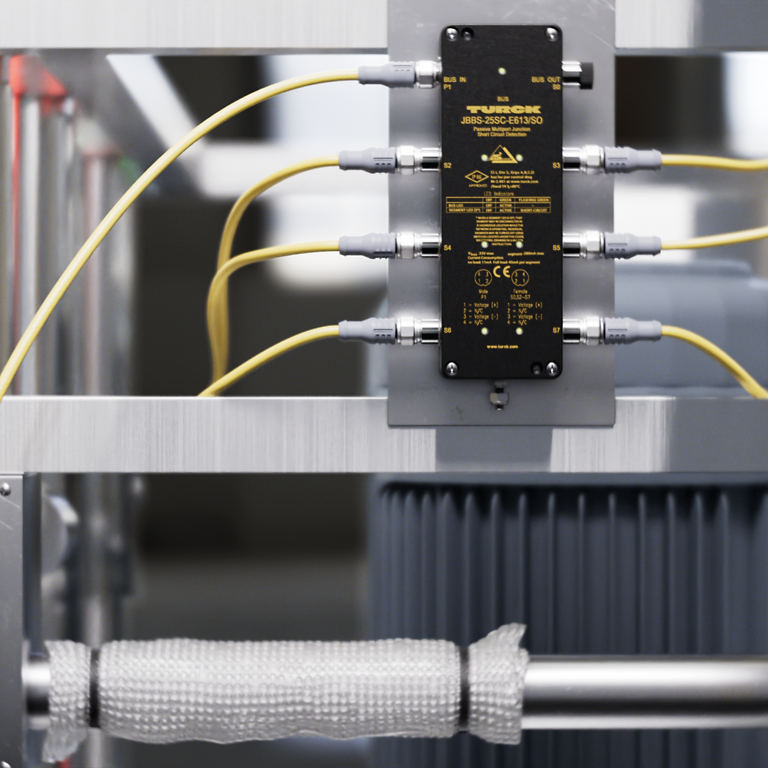

Turck's NIC series inductive coupler set enables contactless, bidirectional transmission of energy and IO-Link data between mobile workpiece carriers and static workstations. They reliably transmit sensor signals across an air gap of up to 7 mm without the need for mechanical contacts. This eliminates the risk of defective plug connectors, reduces maintenance costs and increases system availability.

Thanks to IO-Link, the workpiece carriers can be uniquely identified via the Application Specific Tag. The machine control system knows at all times which components are being processed. This enables seamless process control.

The NIC couplers are ready for immediate use as a plug-and-play solution and do not require any complex parameterization. Their generous tolerance range allows for easy installation with a reliable connection – even with lateral offset. This reduces installation and maintenance costs and optimizes material flow in highly automated production lines.

"The NIC couplers provide wear-free transmission of energy and data for reliable, maintenance-free automation."

Dustin Küpper | Product Manager Position/Proximity Sensors | TURCK GmbH