Inductive couplers with high shock resistance

TURCK's new NIC series transmits data and energy without contact at up to 18 watts of power

Benefits

- Reduced plant downtime due to worn mechanical connectors

- Higher plant productivity thanks to fast and reliable coupling

- High degree of mounting flexibility due to generous angular displacement

TURCK has reissued its inductive coupler sets, with the new models providing not only performance improvements, but also new functions such as selective pairing. With a startup time of 600 ms, the NIC couplers enable shorter production cycles and thus increased productivity.

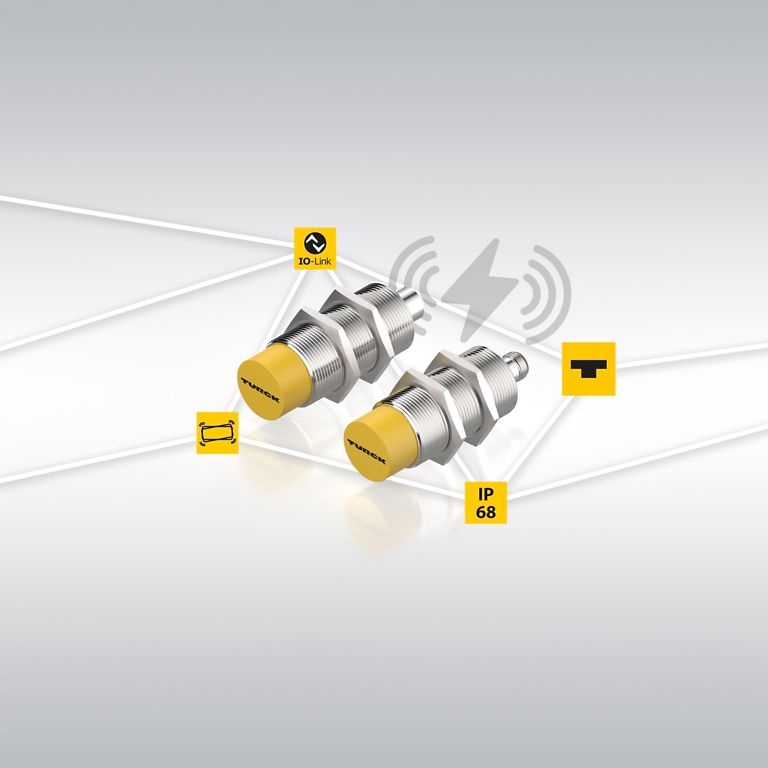

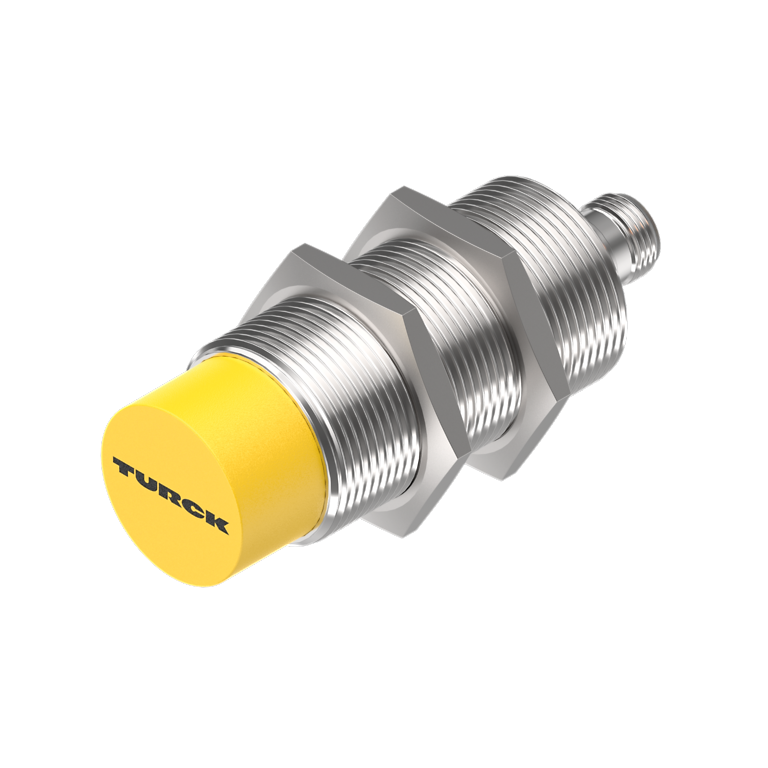

Robust and reliable

Thanks to IO-Link COM3, the NIC couplers support the maximum data transfer rate of 230.4 kbit/s. These robust couplers can withstand high shock loads and transmit 18 W of power via a 7-mm air interface. As "contactless connectors," they are completely wear-free and permanently sealed with IP68 protection. A tolerated angular displacement of up to 15° and a parallel displacement of up to 5 mm ensure a high degree of mounting flexibility. The diagnostic function detects the presence of the secondary part and any metal objects in the air gap.

Selective pairing unique on the market

Bidirectional communication means that actuators can be addressed and sensor signals can be collected. In addition to "dynamic pairing," i.e. the coupling of any primary and secondary parts, the couplers also support selective pairing, a unique feature on the market in which a primary part can only communicate with selected secondary parts. The device can be addressed directly via IO-Link for this purpose. Typical applications of NIC couplers are interchangeable tools, rotary indexing tables or driverless transport vehicles.