Contactless transmission of power and switching signals

Turck's inductive couplers transmit power and switching signals without contact in sterilization systems at the Swiss company Hanag Steriltechnik AG. The ID of the IO-Link sensor is also used to reliably identify each container

Quick read

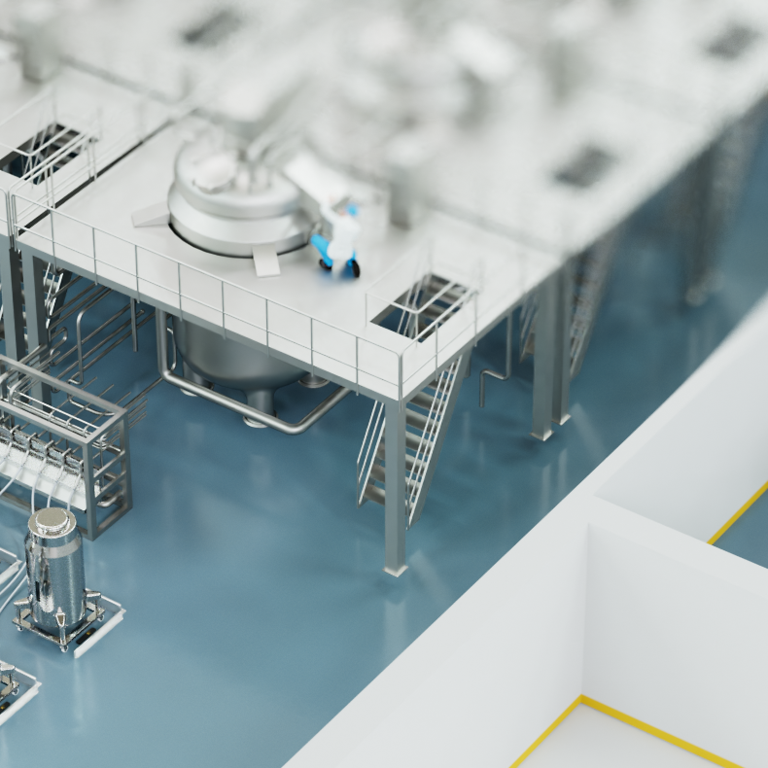

The Swiss company Hanag Steriltechnik AG manufactures equipment for the treatment of caps and stoppers for the pharmaceutical industry. These are sterilized with different process sequences, which requires reliable identification of each container in the process. Where plug-in contacts have been used for a long time, the company today relies on contactless data and energy transmission using an inductive coupler, which identifies every container via the "Application Specific Tag" of the IO-Link sensor and at the same time ensures the correct position of the containers in transport trolleys at the transfer stations.

When pharmaceutical manufacturers fill their solutions for intravenous infusion, the final step in the production process is to sterilize the ampoules, caps, and closures. This is often done with plants of Hanag Steriltechnik AG from Switzerland. The Oberwil-based company is one of the major Swiss suppliers in plant and container construction and has gained a good international reputation thanks to its stopper and cap treatment systems. The main focus is on sterile applications. Anyone who browses Hanag's reference list will see the who's who of European pharmaceutical manufacturers.

"The TURCK coupler system turned out to be the most suitable one for us. In particular, the heat generation is lower than with the comparison products, and the NIC coupler also has an IO-Link interface."

Eric Netzhammer | Geschäftsführer | Hanag Steriltechnik AG

Sterilization process

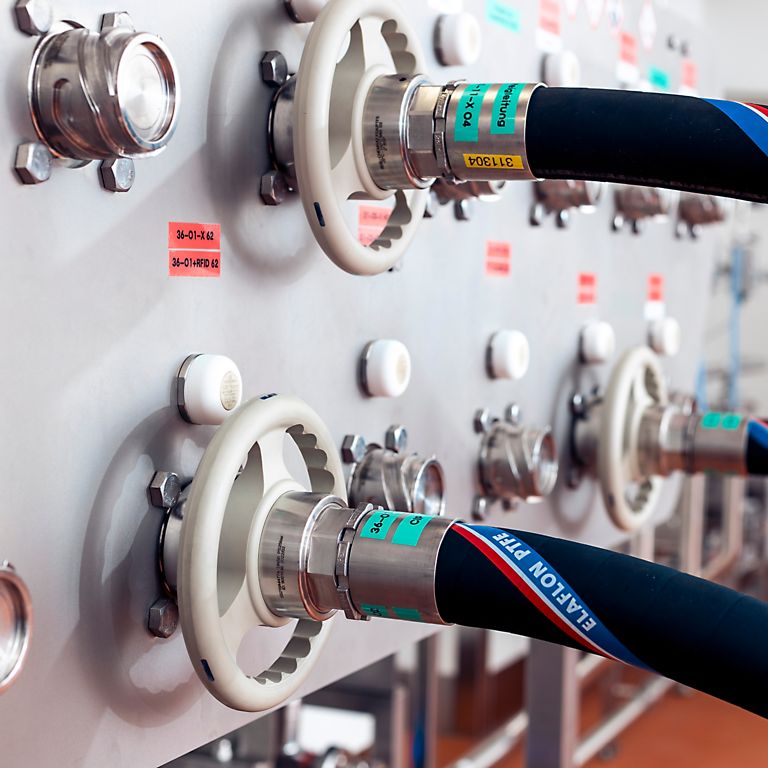

The cap and stopper treatment process is divided into the sections Washing, Sterilizing, Drying and Cooling. To do this, the packaging materials are filled into containers, which then pass through the various process stations. The containers are mobile in their trolleys and can be rotated in them. The pharmaceutical manufacturer runs various programs for different types of stoppers and caps. Therefore, the customer wanted the containers to be identified at the individual stations. In the past, Hanag solved this with a plug contact. This included a binary code, which was used to uniquely identify each container.

Eric Netzhammer, , along with his team, wanted to establish a contact-free connection between the containers and the transfer stations. This saves the customer from having to connect the plugs. Together with the automation consultants of Turck's Swiss sales partner Bachofen, Netzhammer and his team compared various inductive systems for contactless signal and power transmission. "The TURCK coupler system turned out to be the most suitable for us," says Netzhammer. "In particular, the heat generation is lower than that of comparable products, and the TURCK NIC coupler also has an IO-Link interface."

Sterilization process

The cap and stopper treatment process is divided into the sections Washing, Sterilizing, Drying and Cooling. To do this, the packaging materials are filled into containers, which then pass through the various process stations. The containers are mobile in their trolleys and can be rotated in them. The pharmaceutical manufacturer runs various programs for different types of stoppers and caps. Therefore, the customer wanted the containers to be identified at the individual stations. In the past, Hanag solved this with a plug contact. This included a binary code, which was used to uniquely identify each container.

Eric Netzhammer, Managing Director of Hanag Steriltechnik AG, along with his team, wanted to establish a contact-free connection between the containers and the transfer stations. This saves the customer from having to connect the plugs. Together with the automation consultants of Turck's Swiss sales partner Bachofen, Netzhammer and his team compared various inductive systems for contactless signal and power transmission. "The TURCK coupler system turned out to be the most suitable for us," says Netzhammer. "In particular, the heat generation is lower than that of the comparable products, and the TURCK NIC coupler also has an IO-Link interface."

Increased process reliability

In addition, the process reliability was increased by checking the rotational position, and identification via the contactless coupler was simplified. The fact that a simple switch is now also used for identification is a capability of IO-Link that was not at all the focus of the development of the intelligent sensor/actuator interface. Today, Hanag saves the need to set up a separate identification solution via plug contacts or RFID.

Customer | www.hanag-steriltechnik.ch

Sales| www.bachofen.ch

Roland Fuchs is a product manager at Turck's Swiss sales partner Bachofen