RFID secures hose connections in ATEX zone 2

B. Braun Medical AG guarantees reliable mixing and filling processes through fail-safe verification of hose connections in ATEX zone 2 – with an RFID solution from TURCK

Quick read

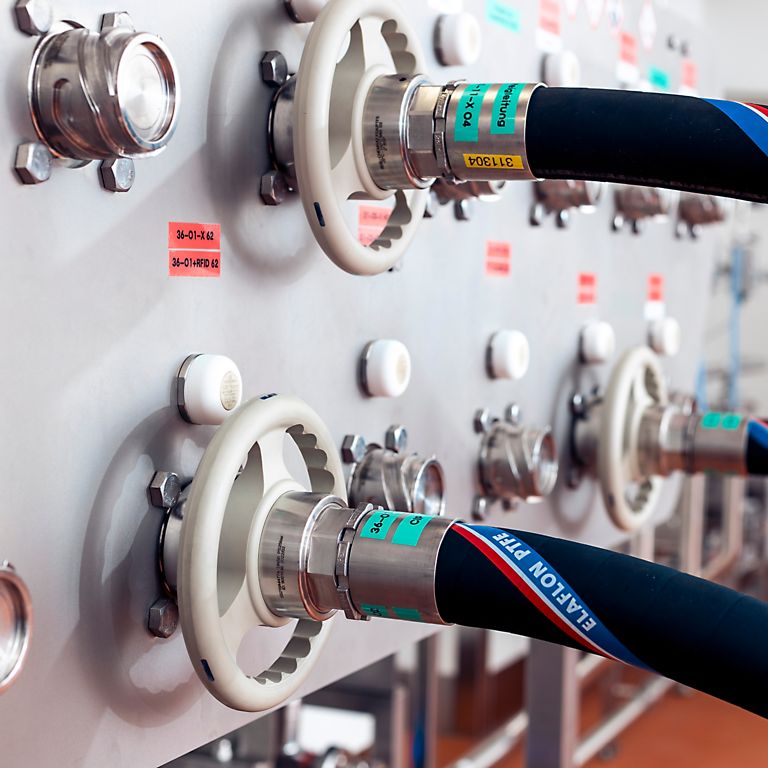

The medical technology company B. Braun Medical AG manufactures medical disinfection and hygiene products as well as pharmaceuticals for the treatment of chronic wounds at its Sempach location in Switzerland. This requires high-precision and reliable mixing and filling processes. In order to meet the strict requirements for safety and quality, an RFID system with TBEN I/O modules from TURCK verifies the correctness of the hose connections in ATEX zone 2. Three RFID tags are located in each of the coupling wheels of the hose connections. The TURCK solution impressed with its ATEX approvals, high levels of protection and Ethernet multiprotocol capabilities.

B. Braun Medical AG is a subsidiary of the German B. Braun Group, one of the leading manufacturers and suppliers of medical technology products. The B. Braun Group employs around 65,000 people in 64 countries, more than 1000 of them in Switzerland. In development, production and distribution, these companies ensure that the healthcare market is supplied with high-quality products.

The production site of B. Braun Medical AG in Sempach in the Swiss canton of Lucerne specializes in the production of medical disinfectants, hygiene products and medicines for the treatment of chronic wounds. Complex mixing and filling processes are carried out here, in which various chemical raw materials are mixed in tanks and then filled. Due to a sharp increase in demand, the company is in the process of doubling its production capacity.

Identification creates security

The core process of the new plants essentially comprises the supply of the various chemical raw materials from the weighing containers to the mixing tanks and the transfer of the finished products to the filling line. Junctions in the system are two hose stations, one of which is located at the loading station and the other at the interface to the filling line. During the process, the hoses must be moved three to four times per batch. In order to avoid confusion with disastrous consequences, the hose stations are integrated into the RFID system, which controls the entire plant. At each connection, an RFID tag on the hose side and an RFID reader/writer must interact with each other. The passage only opens if the system has identified the correct medium.

"It is not easy to find products with explosion protection zones 1 and 2 that are also suitable for clean rooms, and vice versa."

Thomas Mühlebach | Leiter Unterhalt und Technik | B. Braun Medical

Communication-capable coupling wheel

There are a large number of hose couplings with integrated RFID code carriers on the market. However, in this case, a standard solution was out of the question in view of the tight space and heavy hoses – a long ball for the inventors among the RFID specialists of Bachofen AG, the national sales partner of TURCK in Switzerland. Their vision: a hose coupling with a coupling wheel, into which the RFID tags are cast.

Together with the specialists for coupling technology and hose systems, MannTek and Schudel AG, Bachofen implemented the unconventional idea and developed a prototype that convinced B. Braun Medical completely. "The specialists at Bachofen have leaned into the task and did not give up until a solution was available, to which we were able to say yes without reservation," explains Thomas Mühlebach, Head of Maintenance and Technology at the Sempach location.

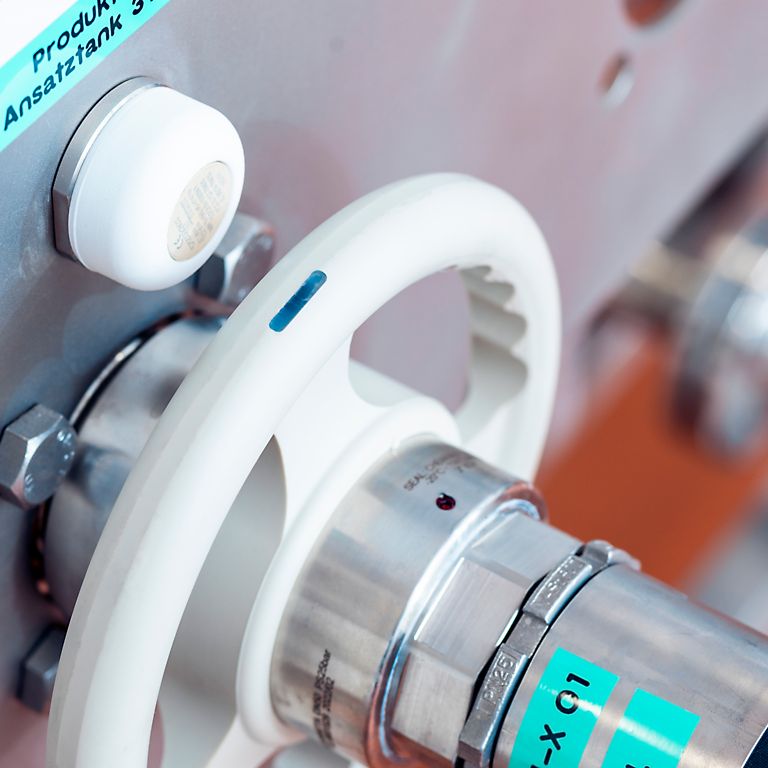

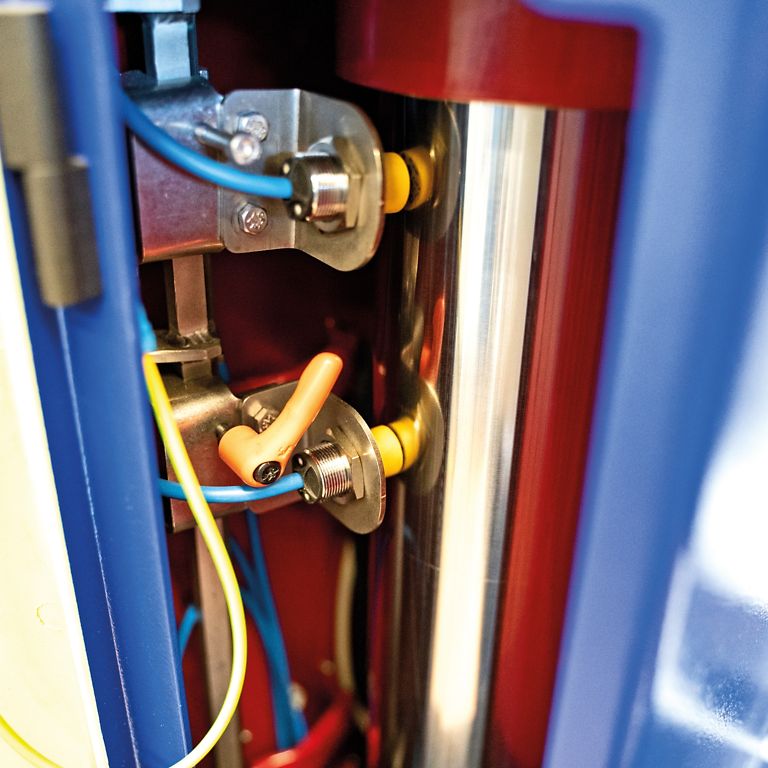

The final rotary wheel version contains three RFID tags inserted at intervals of 120 °, the signals of which identify the connection at lightning speed when screwed in and enable the flow if the result is positive. To integrate and control the coupling solution, Bachofen used TURCK's BL ident RFID system with TBEN I/O block modules with IP67/IP69K degree of protection. These are also approved for use in ATEX zone 2 with special protective housings, which is rarely the case with Ethernet I/O modules. The read/write heads used can also be used in zone 2, and the TN-R42TC-EX can even be used in zone 1. The TBEN modules, with their multiprotocol capability, can be integrated into any industrial Ethernet network that supports Profinet, EtherNet/IP, or Modbus TCP. B. Braun Medical uses OPC UA to communicate with the higher-level production system.

Precision with easy handling

The new system is extremely precise: the three RFID tags in each coupling wheel ensure that they are read quickly and reliably. The tags used in the IN TAG 200 model are specially designed for use in explosive areas. The TN-EM30WD-H1147-EX read/write head is also approved for use in hazardous areas up to zone 2. Its housing made of stainless steel and liquid crystal polymer meets the IP69K degree of protection and can withstand even the toughest cleaning processes.

Hose couplings and RFID verification

Once the hose is connected, the read/write head reads the information from the RFID tags in the coupling wheel. The data collected in this way is immediately compared with the information about the tank. This ensures that only the correctly identified components are connected to each other. If a faulty coupling is detected, the system blocks the flow. This automated verification process has several advantages: on the one hand, it increases safety and on the other hand, it improves efficiency, since the verification process takes place quickly and reliably without the need for manual checks.

Optimized production reliability and reproducible quality

In addition, the module enables the RFID tags to be written with specific data about the processes carried out and the materials. This data recording not only supports traceability in quality control, but also optimizes the documentation and compliance of production processes. For example, the time of the last cleaning of a hose can be stored on the RFID tag. If this period is exceeded, the system automatically prevents the material flow to ensure the sterility and quality of the production process. This ensures that both the production reliability and the constant quality of the products are guaranteed.

Summary

The development of the special solution was a highlight in the collaboration between B. Braun Medical and Bachofen. At the product level too, Bachofen was able to fully meet the requirements of the plant operator with the automation components from TURCK and Banner Engineering. In addition to the RFID components, TURCK supplied numerous TBEN-L5-8IOL I/O block modules, which, among other things, connect the valves, as well as all Ethernet, power and many sensor-actuator cables.

"It is not easy to find products with explosion protection zones 1 and 2 that are also suitable for clean rooms," says Thomas Mühlebach. "Bachofen understood what we need and supported us with competent advice and suitable products during the evaluation."

Customer | www.bbraun.de/de

André Ammann, Key Account Manager for Pharma Europe at TURCK