Automation and control of hydrogen refueling stations

At Portugal's first hydrogen refueling station, TURCK's interface devices ensure reliable isolation of Ex signals, while Banner's safety ensures the safety of the entire system

Quick read

PRF Hydrogen Solutions delivered the first hydrogen refueling station for H₂ buses for the Portuguese municipality of Cascais in record time—despite the added challenges of pandemic-related supply chain disruptions. The system features a modular design, so it can be transported at any time as needed. Bresimar Automação, TURCK's representative in Portugal, supported PRF with the appropriate interface technology for safe processing of Ex signals, as well as safety controllers from Banner Engineering that ensure the overall safety of the H₂ refueling station.

The first hydrogen refueling station in Portugal is operated by the municipality of Cascais in the Lisbon region to fuel its hydrogen buses. This commitment is no coincidence, since two of the largest manufacturers of hydrogen-powered buses—CaetanoBus and Toyota—produce their hydrogen buses in Portugal.

For the first time, these buses are being refueled at a mobile hydrogen refueling station from PRF Gas Solutions. The company has specialized for 30 years in systems for distributing, compressing, storing, refueling and transporting natural gas—and since 2021, hydrogen as well.

PRF received the tender for the first hydrogen refueling station in the middle of the COVID-19 pandemic. Supply chains were under particular strain at the time, and as a result, replenishment and delivery lead times for many industrial goods increased. PRF proactively ordered hydrogen compressors, valves, piping and other components for stock so it could build a hydrogen refueling station in the shortest possible time.

This foresight quickly paid off when the municipality of Cascais purchased two hydrogen buses and commissioned PRF to build the hydrogen refueling station. Even with proactive procurement, there was only a little over a month to implement the H₂ station. "There was very little time to design everything, perform the calculations, size the mechanics and structure and take care of everything else. We ultimately received the compressor we had ordered two days before the deadline," says Hugo Antunes, project engineer for hydrogen refueling stations at PRF, describing the project's tight timeline.

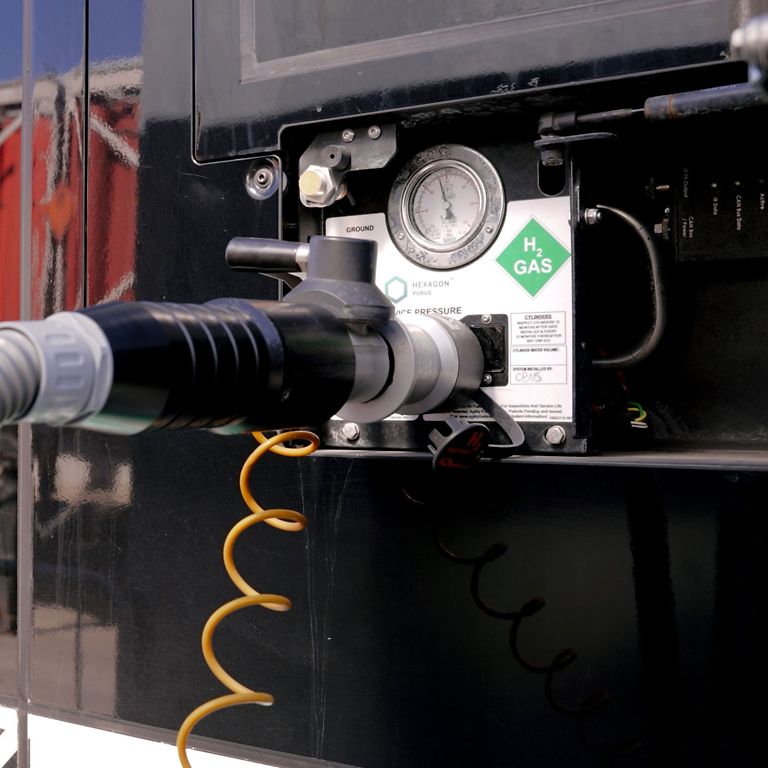

Automation and control of hydrogen refueling stations are significantly more complex and demanding than for conventional gasoline and diesel stations. During refueling, the vehicles exchange pressure values, temperatures and other data with the fueling system via an infrared interface to ensure a smooth and safe fueling process. In the event of a malfunction or emergency, the system is immediately brought into a safe state.

" Working with Bresimar and TURCK enabled us to ensure that our systems not only operate safely and efficiently, but are also future- proof ."

Hugo Antunes | Projektingenieur | PRF

Technological support from Bresimar and TURCK

For the electrical control and safety of the plant, PRF turned to its long-standing automation partner Bresimar Automação, TURCK's representative in Portugal. Bresimar and PRF have been working closely together for more than 20 years. Thanks to this long-standing partnership and the expertise of Bresimar's employees, the automation specialists were able to provide decisive support—even for the relatively new hydrogen refueling station project. "The galvanic isolation barriers from TURCK supplied by Bresimar were particularly important for us," explains Hugo Antunes. "These barriers were essential to ensure the connections between the ATEX and non-ATEX areas of the plant."

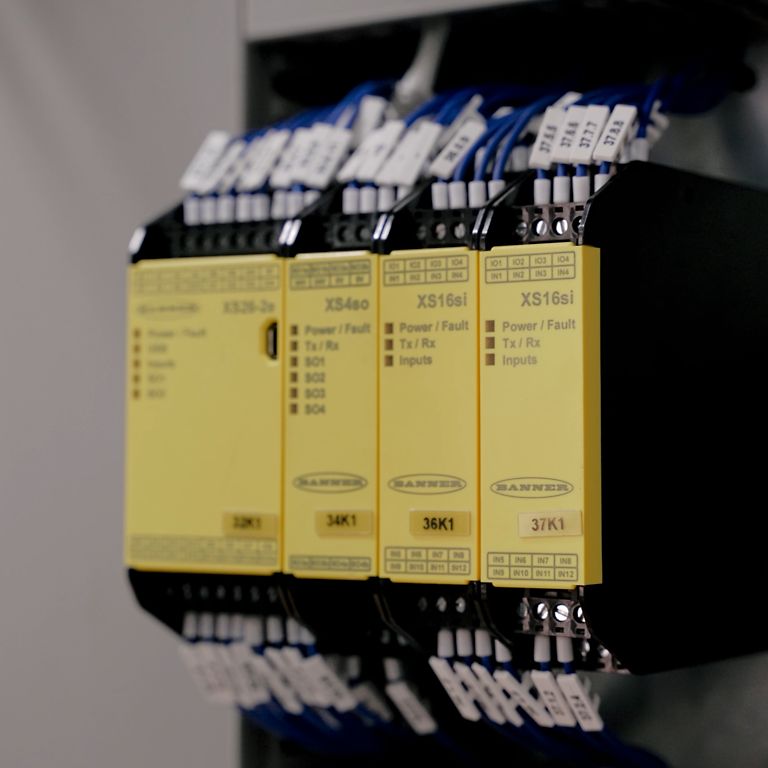

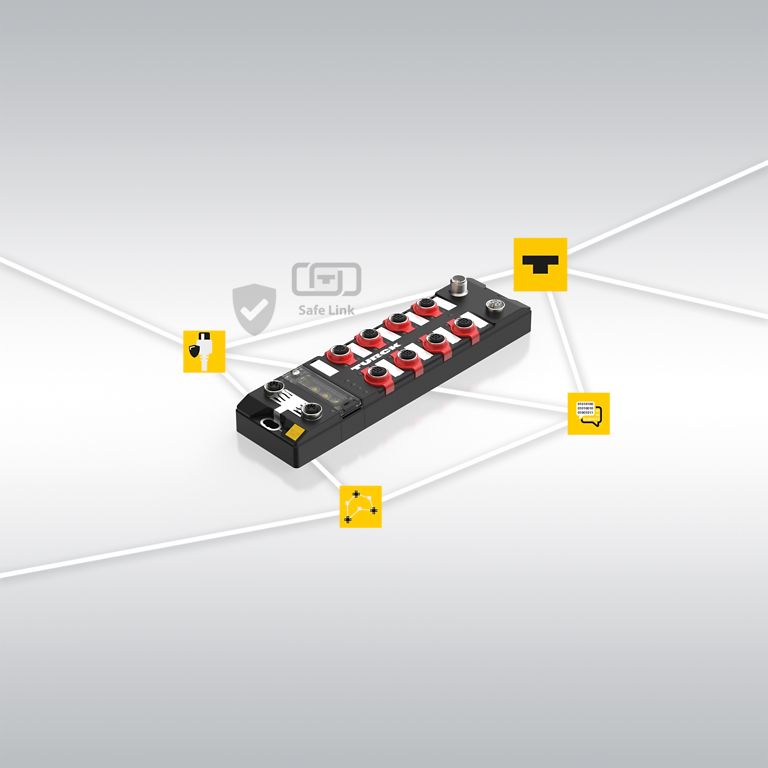

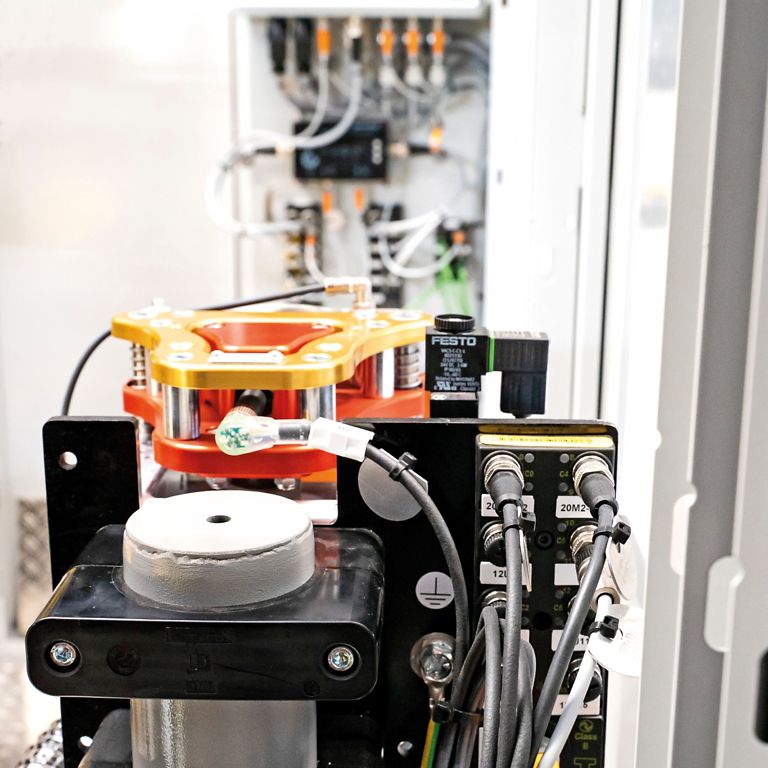

TURCK interface devices handle the isolation of intrinsically safe signals and their preprocessing. At the refueling station, for example, the dual-channel IM33-22Ex-HI isolating transducers and the single-channel IM33-14EX-CDRI units are used. These devices, along with other variants, process temperature and pressure signals and forward them to the station's Siemens control system. Control of all safety-related processes is handled by the XS26 safety controller from TURCK's strategic partner Banner Engineering.

Flexible thanks to modular design

PRF Gas Solutions' hydrogen refueling station is housed in a 20-foot container and can therefore be transported if required, as can the three high-pressure modules for hydrogen compression. "This modular structure enabled us to work flexibly and efficiently," emphasizes Hugo Antunes. "We were able to complete the system on time because we already had many of the required components in stock."

TURCK's galvanic isolation barriers impressed with their competitive pricing and delivery times, as well as their reliability. "Another major advantage was the excellent after-sales support we received from Bresimar," the project engineer adds.

Success and expansion

The hydrogen refueling station in Cascais proved to be an immediate success. It not only served to fuel the locally deployed hydrogen buses, but was also used by Toyota to refuel its hydrogen buses and cars produced in Portugal for the first time. "So far, we've dispensed more than 26 metric tons of hydrogen and completed over 2000 refueling operations without any outages," reports Antunes.

The success of this first station prompted the municipality of Cascais to issue a tender for a larger, permanently installed hydrogen refueling station, which PRF also won. The new station will include four compressors and on-site hydrogen production with a capacity of one megawatt via electrolysis. "This plant will be one of the largest in Europe and will supply fully green hydrogen, provided the electricity comes from renewable energy sources," the project manager explains.

Summary

The project shows how forward-looking planning, a modular design and collaboration with reliable technology partners such as Bresimar and TURCK can create innovative, sustainable infrastructure that makes an important contribution to sustainable mobility in Europe. "We are very proud of what we have achieved and are looking forward to the upcoming projects," project manager Hugo Antunes summarizes. "Working with Bresimar and TURCK enabled us to ensure that our systems not only operate safely and efficiently, but are also future-proof."

Customer | www.prf.pt/en

John Spijkers is Sales Manager MEIA and Sales Partner Europe at TURCK