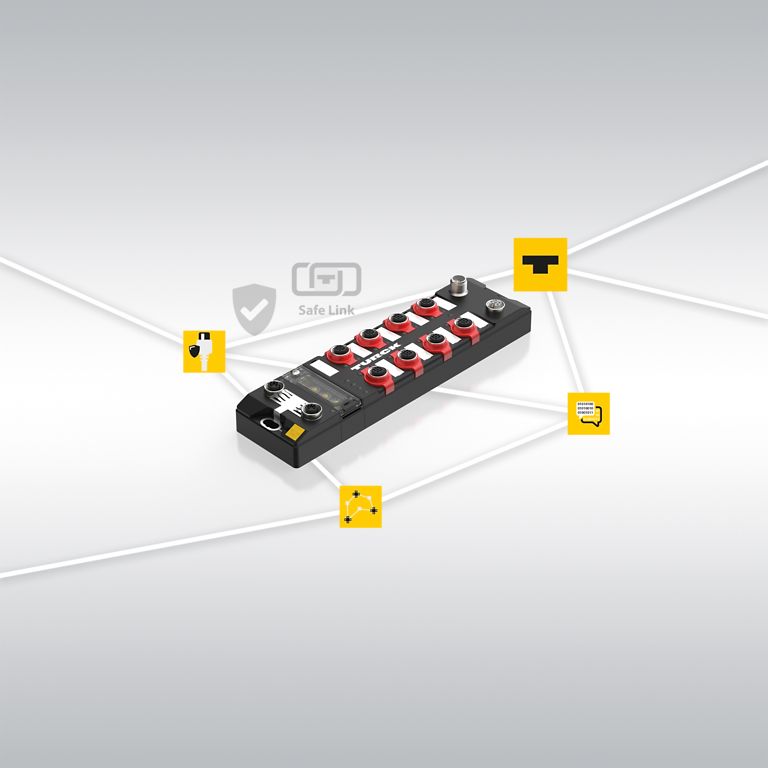

Modular safety network thanks to Safe Link

TURCK's networked safety platform based on the Safe Link protocol and the secure Ethernet multiprotocol I/O module enable efficient and flexible safety solutions for small to medium-sized plants — up to ATEX Zone 2/22

Quick read

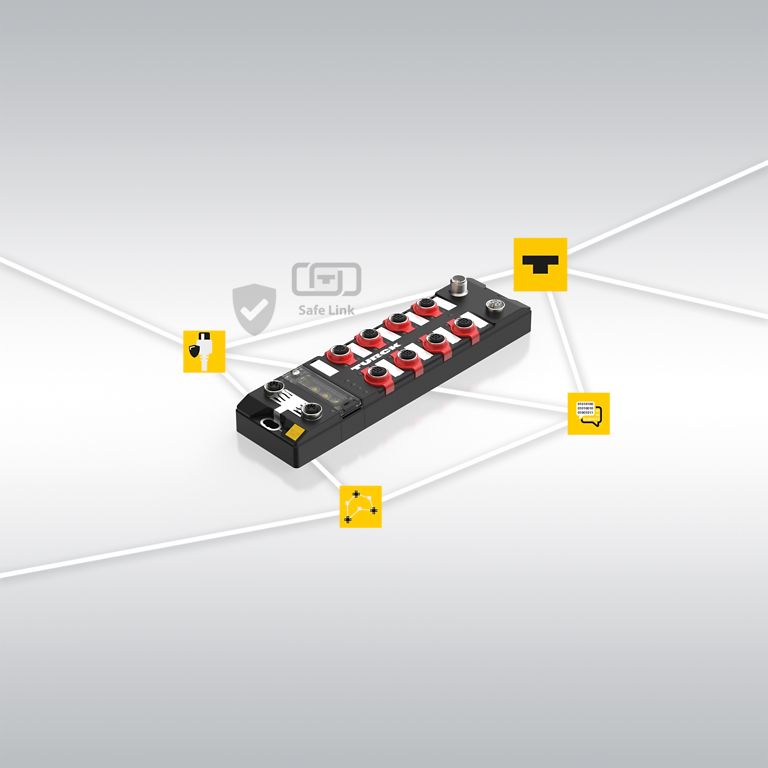

With Safe Link and the safe TBEN-LL-4FDI-4FDX Ethernet multiprotocol I/O modules, TURCK offers an efficient and flexible solution for machine safety, especially for small to medium-sized plants. Thanks to the Ethernet multiprotocol, decentralized installation of the IP67 modules and the option of safely networking up to 31 modules with Safe Link, an easily scalable, modular safety net without switch cabinets is created. This solution reduces the amount of cabling required and facilitates installation — the ATEX approval also allows use in Zone 2/22 hazardous areas.

Machine safety plays a central role in modern industrial environments and includes a wide range of technologies and measures aimed at preventing accidents and injuries. In an increasingly complex industrial landscape, it is crucial that safety controllers do not work in isolation, but are integrated and networked. For example, a safety light curtain can stop a production line immediately if an employee enters a hazardous area, while an emergency stop system is activated to shut down nearby machines. This coordinated communication between the safety components creates a comprehensive safety network that not only ensures the safety of the employees, but also maximizes the operating time of the machines.

I n practice, this means that an operator working on a punching machine, for example, can be confident that when the safety curtain is triggered, not only is the machine itself stopped immediately, but also all conveyor belts and supply systems in the entire area. This integrated response not only prevents injury, but also minimizes the risk of machine damage from suddenly stopping isolated parts of the system. Another example is a robot arm in a production line: If a safety laser detects that an employee is moving too close to the operating area of the robot, not only is the robot stopped, but also all machines that interact with the robot. This ensures that the entire area is safe and that no isolated system part continues to run in an uncontrolled manner.

Safety in small to medium-sized plants

The increasing complexity of industrial environments demands integrated and networked safety solutions. Users often face specific challenges, particularly in small to medium-sized plants with a moderate number of safety applications. Another critical issue is the lack of flexibility of traditional solutions in dynamic production environments. Production lines that are frequently modified require scalable safety solutions. Traditional, central safety control systems are often too big for the specified applications and lead to high acquisition and operating costs. Furthermore, there is a considerable amount of cabling work and the complexity of installing central PLC systems. Adaptations to changed production requirements or plant extensions are often expensive and difficult to implement with central safety solutions.

Coordinated safety measures using networking

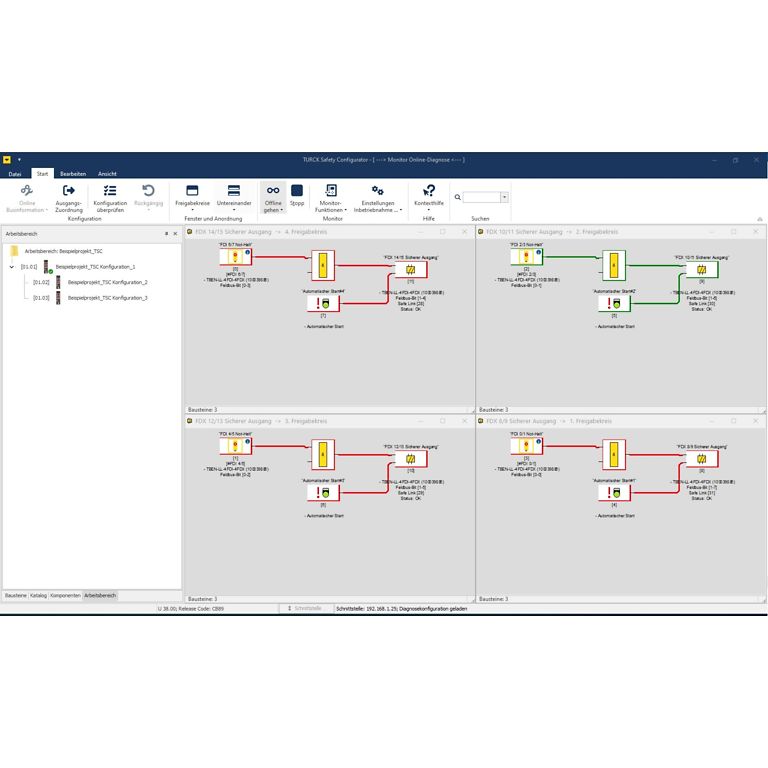

Thanks to its Safe Link protocol, TURCK's secure TBEN-LL-4FDI-4FDX multiprotocol I/O modules can communicate securely with each other and with other devices in the network. This networking enables a coordinated response to safety events along the entire production line. For example, a module that receives an emergency stop signal can forward this information immediately to all other modules so that all affected machines are stopped immediately. This not only ensures the safety of employees, but also minimizes the risk of machine damage and production downtime. The ability to communicate in real time between the modules ensures that the safety measures are always synchronized, particularly fast and therefore efficient.

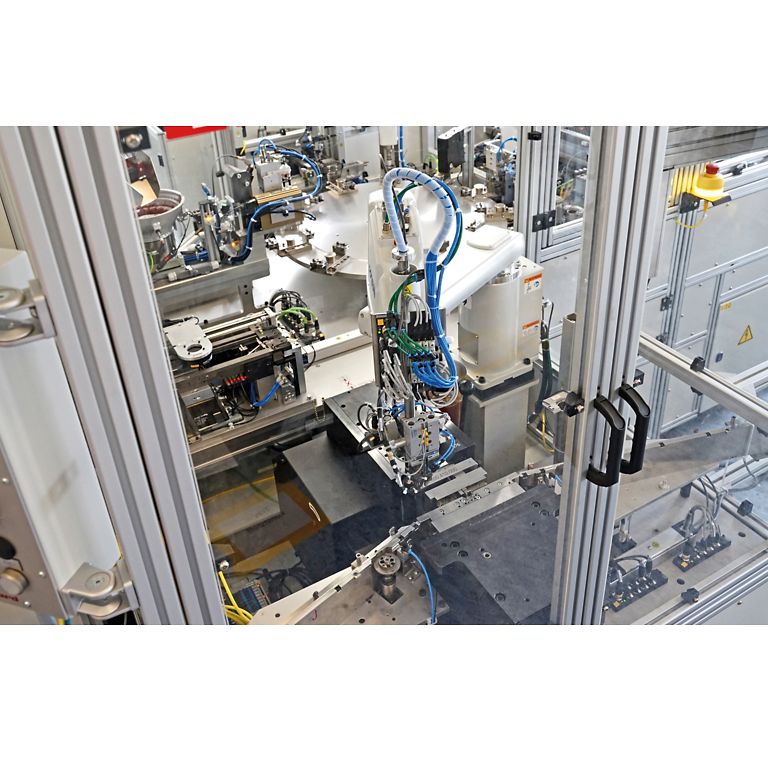

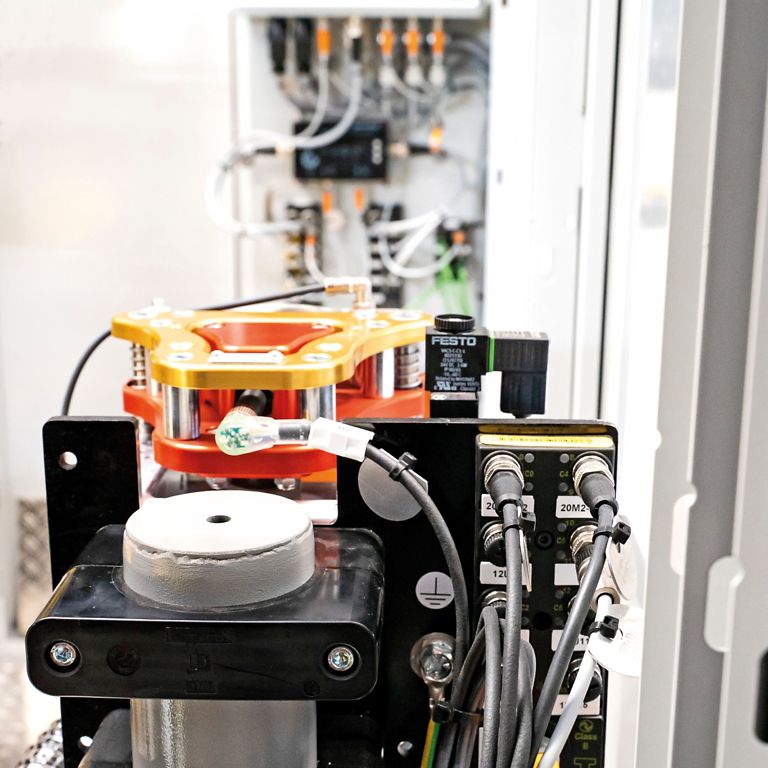

Decentralized installation for maximum flexibility and efficiency

The decentralized installation of the safe TBEN modules offers decisive advantages, especially in smaller production lines, where space and cabling are often a problem. The IP67 modules can be installed on the machines exactly where the safety functions are required. This reduces the need for central switch cabinets and the cabling required, which not only simplifies installation, but also the maintenance and expansion of the systems. The modules offer direct connection via M12 L-coded power supply connections and M12 D-coded Ethernet connections for reliable network communication. This enables safety-related functions to be implemented decentrally, precisely at the source, significantly increasing the flexibility and efficiency of the production line, as short paths for safety signals allow faster cycle times.

An outstanding feature of the TBEN-LL-4FDI-4FDX multiprotocol I/O modules is their variability: Each module can be added, removed or replaced independently, enabling rapid adaptation to changing production requirements. The ability to network up to 31 modules in one application offers considerable flexibility in the design and expansion of safety solutions. Furthermore, each module provides 127 diagnostic bytes for monitoring and rapid error diagnostics, which further increases operational safety. There are two bytes per module for safety-related input and output data as well as two bytes of non-secure fieldbus bits that can be used for communication with a non-secure PLC. The integration of single- and two-channel inputs as well as secure outputs, which can be used directly to control machines and drives, allows the modules to be easily integrated into existing safety networks. This scalability enables companies to respond flexibly to market requirements and technological developments without having to invest in rigid and cost-intensive safety solutions.

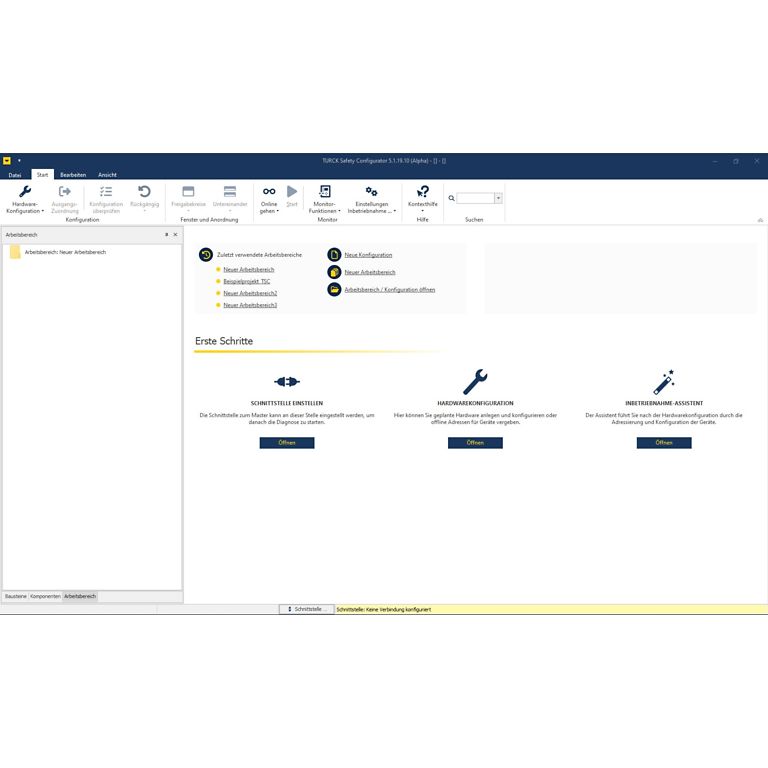

Seamless integration through multiprotocol

The secure multiprotocol TBEN modules support a wide range of communication protocols, including EtherNet/IP, Profinet and Modbus TCP as well as the safety protocols CIP Safety and Profisafe. This capability allows organizations to maintain their existing network infrastructure while still integrating the new security modules, saving time and money. This versatility makes the modules particularly attractive for companies that work in heterogeneous system landscapes and require a uniform, flexible safety solution.

Safe solutions for hazardous areas

For applications in hazardous areas, the multiprotocol I/O modules offer a decisive advantage thanks to their ATEX approval for Zone 2/22. The certification ensures that the safety solutions work reliably even under extreme conditions and comply with legal regulations. By using these modules in hazardous environments, companies can ensure that their employees and plants are optimally protected, which greatly expands the application possibilities and creates additional flexibility in sensitive areas.

Summary

The integration of TURCK Safe Link into the safe TBEN-LL-4FDI-4FDX multiprotocol I/O modules enables companies—especially those with small to medium-sized plants—to implement a flexible, scalable and cost-efficient safety solution up to ATEX Zone 2/22. The decentralized IP67 concept allows customization to suit individual requirements, while the multiprotocol capability facilitates integration into existing systems. With the ability to network up to 31 modules and integrated diagnostic functions for fast error detection, this solution offers a high level of scalability and operational reliability. All in all, the TBEN modules represent an efficient and economical safety platform that not only offers the highest safety standards, but also contributes to maximizing operating time and minimizing machine damage.

Author | Michael Flesch is a Product Manager for Safety systems at TURCK