Decentralized safety technology for modular production

AWL-Techniek uses scalable safety technology directly on the modules in its M-Line machine platform, implemented with TURCK's IP67 IO-Link and safety I/O concept

Quick read

With its M-Line, AWL-Techniek is a pioneer in modularizing production lines. When implementing the modular concept, TURCK provided optimal support to the Dutch machine builder with a decentralized IP67 safety concept. The combination of IO-Link and hybrid safety I/O block modules saves substantial wiring effort because the entire safety architecture can be mounted outside the control cabinet. Consistent galvanic isolation of sensor and actuator power enables decentralized safety shutdown of actuator groups at the IO-Link I/O hubs. The binary interface also provides valuable diagnostic data for 'Lyla,' AWL's dashboard solution for visualizing and analyzing data. The project shows how modular machine design creates flexibility and shortens throughput and commissioning times.

Anyone who configures a kitchen using an online configurator today sees a clear example of modularity. The individual modules are in turn made up of submodules for the side panels, base panels, back panels and shelves. In the end, users can choose from various finishes for the fronts and trim panels as well as a handle design and a matching countertop.

The example of a DIY kitchen clearly shows that modularity is not conceivable without standardization. Only with defined distances, dimensions, drilling patterns and water or gas connections can a modular production strategy deliver its benefits: a wide range of products, flexibility, short throughput and delivery times and competitive pricing.

With these and other arguments, Matthijs Varwijk demonstrates the value of the modular machine concept to prospects and customers. Varwijk is an R&D project manager and is also responsible for the modularization strategy at Dutch machine builder AWL-Techniek in Harderwijk. With more than 750 employees at five locations worldwide, AWL has made a name for itself primarily in the automotive industry, with its automated welding and joining lines. Major automakers, suppliers and many other customers worldwide use the Dutch company's machines in their production lines.

In 2017, an interdisciplinary team led by Varwijk began shifting AWL's machine portfolio to a modular approach and, step by step, defined the M-Line standards. Early on, he also had to secure internal buy-in. The benefits are not always obvious during the transition from a traditional to a modular production layout. Defining standards comes first and that is often associated with constraints.

"We need a partner who is also a good global fit for us. We found that partner in TURCK."

Matthijs Varwijk | Projekt-Manager R&D | AWL-Techniek

A standardized frame creates flexibility and reduces costs

AWL set the first standard with the name of the product line. The M-Line stands for a modular product line and the term "Line" also reflects the production line the individual modules are assembled into. Each module is built on a steel frame structure designed to fit into an ISO container, saving significant time and cost during transport and commissioning. The customer can also easily expand or reconfigure the system later because the modules can be rearranged in the production hall using appropriately rated forklifts.

Modularization requires standards

With the base frame, three core module types were defined from which the M-Line is to be built: an operator module where a worker can load parts and start processes, an indexer module that includes rotary tables or other fixtures for handling the workpieces and a process module that machines workpieces, for example using welding robots or other tools.

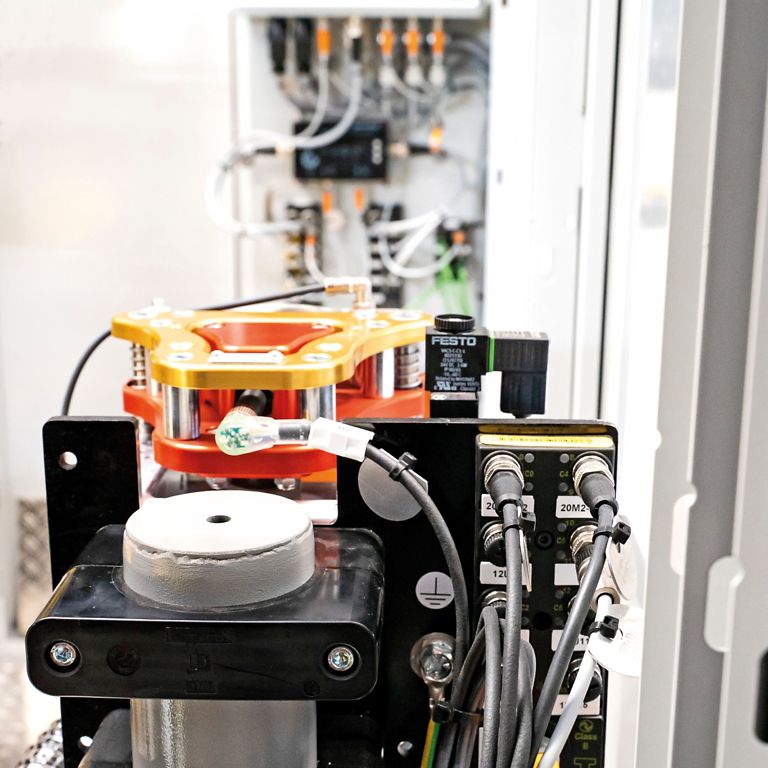

The goal: an empty control cabinet

AWL also benefits from TURCK's Ethernet multiprotocol technology for I/O modules. It allows the manufacturer to use identical I/O block modules in every M-Line module regardless of whether the customer prefers a Profinet or EtherNet/IP controller. "We wanted as many standardized components as possible and a control cabinet that is standardized to a large extent. Ideally, one day the control cabinet will contain only a PLC and a power supply," says hardware engineer Jasper van Kooij. That has not been achieved yet, but there is already plenty of unused space in AWL's module control cabinets. TURCK's IP67 I/O hybrid components for standard and safety signals also play a role.

"Only TURCK could offer us the complete package and consistently separate V1 and V2 circuits."

Jasper van Kooij | Hardware-Ingenieur | AWL-Techniek

TURCK's modular IP67 IO-Link Safety solution impressed AWL with scalable safety technology

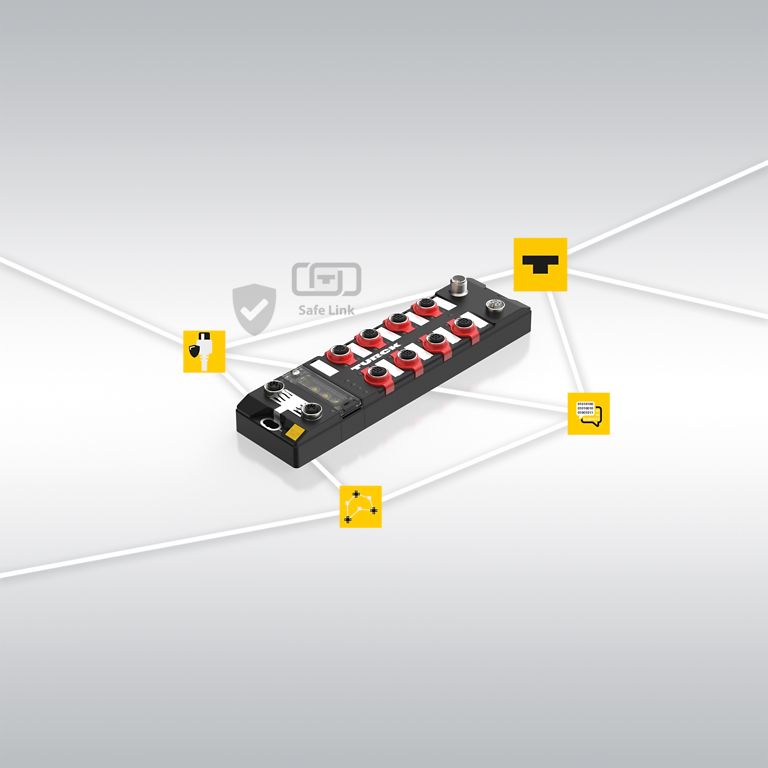

AWL opted for TURCK's modular IP67 IO-Link Safety concept: at the core of the solution is the hybrid TBPN safety I/O module. The module includes an integrated safety controller that communicates with the controller via PROFIsafe over Profinet. It provides four safety I/Os, two standard digital I/Os and two IO-Link ports. The TBSB safety shutdown box is connected to one of the safety I/Os and safely switches off the V2 actuator supply in an emergency.

Power for all modules is also routed through the safety shutdown box. This ensures, for example, that in an emergency stop no actuators remain energized and nothing in the machine can move. The sensors remain active because they are supplied via V1. This means the machine is always visible to the control system. The digital sensors and actuators of the weld cap cutters are connected to I/O hubs which in turn communicate with TURCK's TBEN-L-8IOL IO-Link master. The IP67 block provides four IO-Link ports to the Class A standard and four to the Class B standard. The latter separates sensor power (V1) from actuator power (V2), allowing the power supply to be safely shut down via IO-Link as well. In similar projects in the US, AWL has already used TURCK's TBIP module. It uses the same hardware as the TBPN but is designed for EtherNet/IP and CIP Safety communication.

Galvanic isolation of sensor and actuator power

"Other manufacturers also offer modules that claim to separate V1 and V2. But when you take a closer look, it is not consistent and V1 and V2 share, for example, the negative pole," says van Kooij, explaining his criticism. A shared ground can be fatal in the event of a short circuit. A simple insulation fault is then enough to undermine the entire safety solution, which is one of the reasons AWL chose a system with complete galvanic isolation. Only TURCK could offer us the full package and consistently separate V1 and V2 circuits."

IO-Link strengthens standardization

By using the IP67 solution including safety and IO-Link I/O hubs, AWL saves a great deal of wiring effort. The junction boxes act as IO-Link devices, capturing digital signals from sensors and actuators and passing them to the IO-Link master. From there, the data is sent via Ethernet to the control system. Another factor for van Kooij and Varwijk was that the bidirectional interface supports standardization of the M-Line. Safe signal transmission over three-wire cables eliminates the need for many specially shielded cable types and special-purpose cables. IO-Link also increases machine availability. The M-Line includes the Lyla dashboard system, which collects data from multiple machines, analyzes it and monitors machine function and performance. This is enabled in part by the diagnostic data available via IO-Link.

Looking for a global automation partner

AWL is building the current M-Line generation for a German automaker or one of its suppliers. In addition to the IP67 concept, the Dutch company values the fact that its project partner TURCK, as an automation partner with a global presence, can offer and support the same solutions for automotive projects in the US, Mexico and China as in Europe. "We need a partner who is also a good global fit for us. We found that partner in TURCK," says Matthijs Varwijk.

Scalability is a key advantage of the M-Line

Modularization at the control level is still underway, so for now, each controls project still has to be set up from scratch, although function boxes can be reused. In any case, the modularization project is never truly finished. AWL's customers have already responded very positively to the M-Line, as they see a major advantage in the scalability of the machines. It is easy to replace an operator module later with an automated solution to increase throughput. It's like a kitchen: when you move, you take it with you and add a few modules.

Customer | www.awl.nl