From harnesses to data streams

B&B Verpackungstechnik relies on modular machine concepts with decentralized I/O technology from TURCK – for greater efficiency, flexibility and digitalization

Quick read

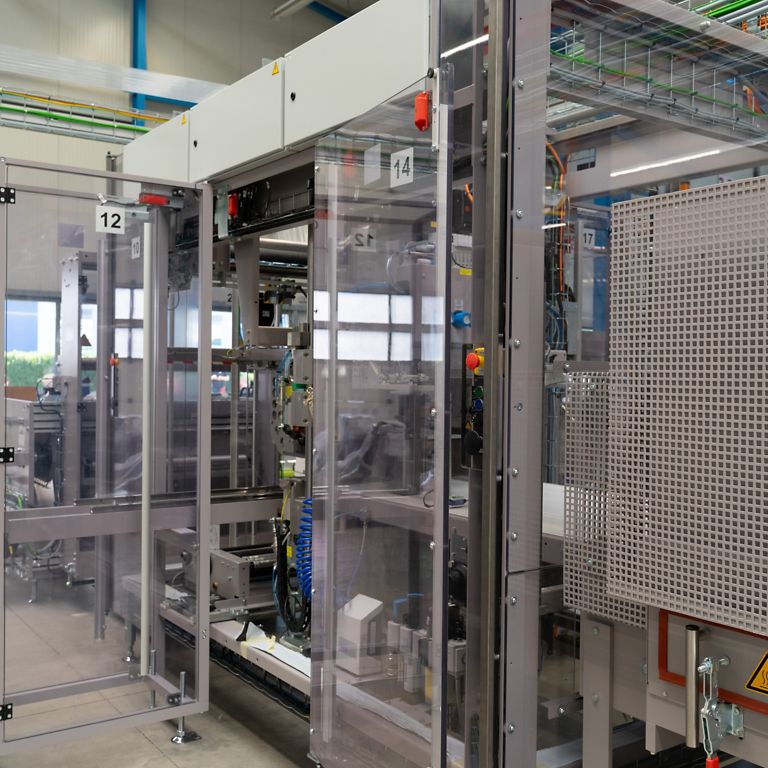

B&B Verpackungstechnik GmbH in Hopsten develops bag and final packaging machines and relies on a modular machine concept with decentralized I/O and safety technology from TURCK. By using robust IP67 modules directly on the machine, the company significantly reduces wiring costs and speeds up installation, commissioning and service. The new architecture creates the basis for end-to-end digitalization – including remote maintenance, scalability and efficient service worldwide

Tradition meets innovation: B&B Verpackungstechnik GmbH in Hopsten produces highly specialized bag and final packaging machines – tailor-made for customers worldwide. The owner-managed company stands for quality, flexibility and creative engineering services. But even in an environment based on decades of experience, technical change is indispensable.

When Tobias Emsmann started at B&B Verpackungstechnik a few years ago, the world of machine electrics looked even different: terminal boxes dominated, thick cable harnesses criss-crossed the machine frames, every change meant effort – expensive, prone to errors, inflexible. The classic wiring with terminal boxes and cable harnesses slowed down efficiency and flexibility. The path to assembly-friendly and service-friendly machines led to consistent modularization – technically, organizationally, constructively. The aim was to create a modular machine concept to streamline machines and processes. "We had machines in which the wiring alone took several hundred hours," recalls the electrical designer. "This was not only expensive, but also error-prone – and it severely limited our flexibility."

“We save up to 240 hours of electrician time per machine – that was one of our major pain points.”

Tobias Emsmann | B&B Verpackungstechnik

Decentralized I/O modules as the key to modularization

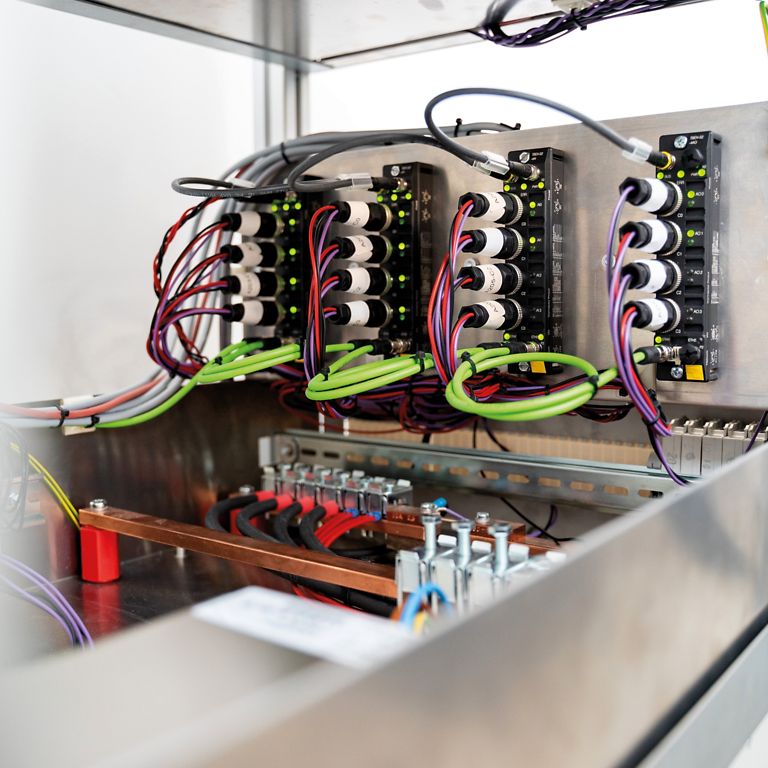

Together with his team, Emsmann developed the new machine concept. Instead of central terminal boxes, decentralized I/O modules were to be installed directly in the machine environment. "We wanted to move away from the rigid thinking of the switch cabinet," he says. "Our machines should have a modular design – like a modular system that can be flexibly adapted." When looking for a future-proof automation solution, B&B initially remained vendor-neutral. Emsmann and his team were specifically looking for I/O modules that capture signals directly in the field. The robust TBEN-L and TBEN-S IP67 block modules from TURCK were selected because of their Ethernet multi-protocol capability, among other things, because they speak both Profinet and EtherNet/IP.

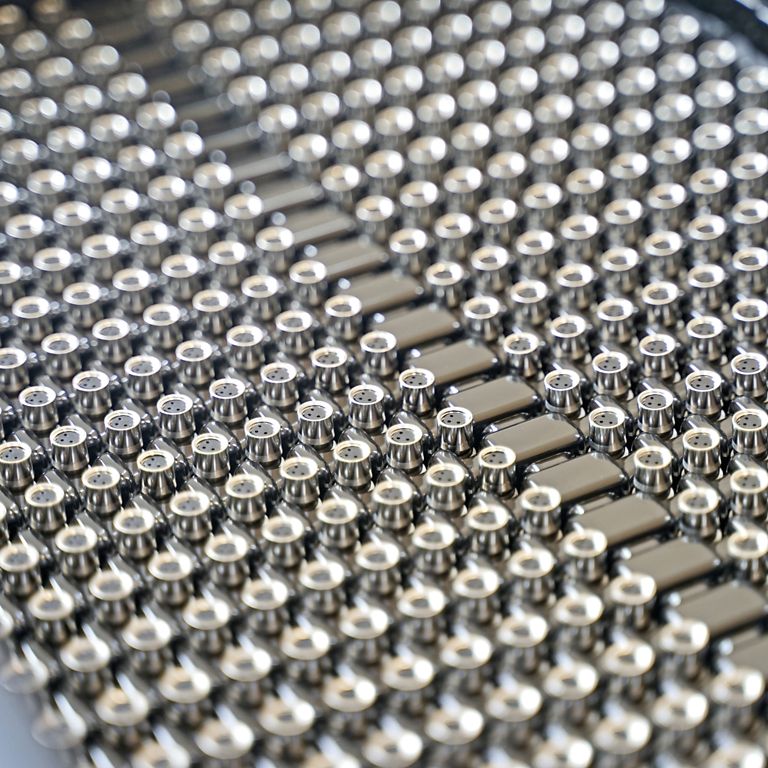

In addition to digital I/Os, the new solution also had to be able to record analog signals decentrally, because a central element in the packaging at B&B is the edge shrinkage: film is blown with hot air so that it lies close to the product. The hot air fans must be precisely controlled via analog inputs and outputs.

In the end, TURCK was also able to convince in terms of functional safety: the hybrid TBPN safety modules enable the flexible integration of safety-related Profisafe and classic Profinet signals on one module – including IO-Link. “I approached the selection independently of the manufacturer and ended up with TURCK,” Emsmann explains.

Up to 240 electrician hours saved per machine

Changing over was a major effort. But it was worth it: cable lengths were drastically reduced, troubleshooting was simplified – and according to Emsmann, B&B today saves up to 240 electrician hours per machine. The company documented production and design in detail and was able to clearly quantify the difference between classic and decentralized construction. "It used to be a huge amount of work to prepare a machine for shipping. Today, we break it down in a modular way, disconnecting the connections – and it is ready for use again on site in no time at all."

The new architecture not only facilitates assembly, but also transport and commissioning. In Hopsten, the machines are completely assembled, tested and then dismantled into modules suitable for transport. Thanks to plug in connections, they can be reassembled quickly on site – without the need for time-consuming rewiring. Even in the event of service, technicians benefit: modules can be easily replaced without having to intervene deeply in the electrical system.

Flexibility through IO-Link and multiprotocol

Another advantage of the TURCK solution is the Ethernet multi-protocol capability of the modules. Whether Siemens or Rockwell – the same modules work in different control environments. B&B also uses IO-Link to connect intelligent sensors and operating elements. This reduces the range of variants in the warehouse and improves diagnostics during operation.

Although every machine is manufactured by B&B on a customer-specific basis, the company relies on consistent standardization. Macro projects in Eplan, modular modules and uniform I/O modules help to master the complexity. Even with different control systems, the field cabling remains largely identical – which is an advantage for design, purchasing and service.

Digitalization and traceability: from the clipboard to paperless production

With decentralized I/O technology, B&B has not only modernized the machine architecture, but has also created the basis for end-to-end digitalization. A central element is the use of Eplan eView in assembly. "We no longer have papers in the assembly hall," says Emsmann. "The mechanics work with tablets. If you change a line or the bus route, they report this back digitally. We can see this immediately in Eplan." This real-time feedback improves visibility and efficiency. Changes no longer need to be documented by hand and transferred later – they are directly incorporated into the planning data.

The road to this did not come without hurdles. "Routine was still missing at first," Emsmann admits. "Many colleagues had wired terminal boxes for years – knowledge of the new technology had to spread first. However, as experience grows, acceptance increases – and the benefits become visible. Despite the hurdles getting started, the team is convinced of the path that has been taken. Digital traceability, remote maintenance and the integration of service information in real time create a new quality in machine support – both internally and externally. "When the customer says today that they would like to have a light barrier at this point – it is no longer necessary for an electrician to come out," says Emsmann. “The service technician can handle this himself, and we monitor it remotely.”

Customer benefits and competitive advantage

At B&B, digitalization is not an end in itself, but rather a strategic tool for working faster and more flexibly. For customers, this means that machines are delivered faster, are available for longer and are easier to expand. Service calls can also be made more efficiently. If the customer releases access, service technicians can switch to the system remotely – for diagnosis or troubleshooting. This gives B&B a clear competitive advantage – especially in times of a shortage of skilled workers and increasing cost pressure.

Partnership on an equal footing

As part of the modularization, close coordination with TURCK was crucial – especially when it came to the integration of the safety modules and communication with different control systems. "These were a lot of small things where software and hardware had to be coordinated in the beginning. But as soon as there was contact between the experts, things went quickly," says Emsmann. He is satisfied with the support: "The support department has always provided us with good assistance." The combination of technical suitability and a trusting partnership was the basis for the project's success.

What started with a packaging machine is now being extended to other machine types. In the future, bag machines and combination systems should also benefit from the decentralized architecture. The experiences from the pilot project are being directly incorporated into the further development. The company is already testing new modules and technologies – for example, for decentralized protection or for controlling variable displacement motors. Condition monitoring and energy monitoring are also planned. The aim is to create a fully digitalized, flexible and maintenance-friendly machine platform.

Customer | www.bub-group.com

Joachim Ricker is a sales specialist at TURCK in Mülheim an der Ruhr