Decentralized control of conveyor technology in battery production

EV battery manufacturers require easily scalable conveyor technology solutions. To enable smart control of variable systems, Intralox developed the decentralized logic module ISC CAM with robust TURCK block I/Os

Quick read

When machine builders need to integrate their solutions into higher-level systems, they usually have a choice between two suboptimal alternatives: either they integrate their controllers into the main line PLC, or they build a control cabinet with a PLC for each system module. Both options are not only complex and expensive, but also insufficiently scalable to meet the growing demands of modern intralogistics systems. That is why belt and conveyor technology specialist Intralox has developed the Intralox Smart Carryway Automation Module (ISC CAM), an autonomous IP67 solution for controlling conveyor systems such as the DARB 4500. TURCK supplied the TBEN block modules for the ISC CAM, the IP67 PSU67 power supplies, and color-coded cables for easy commissioning and control cabinet-free installation.

E-mobility is revolutionizing the global automotive market. It is not only car manufacturers who are feeling the increasing demand for alternative drive concepts, of which electric vehicles are currently the most important. The entire supplier market is being challenged to meet the changing requirements. Above all, the production of lithium-ion batteries must keep pace with the demand for electric vehicles. "We have customers who need to scale very dynamically to meet the requirements of electric vehicle manufacturers," says Martina Costa, Business Development Analyst for the Automotive Team at Intralox in Amsterdam, one of the leading conveyor technology and material flow specialists for numerous industries. For the automotive market, Costa is certain that "battery manufacturers cannot achieve the necessary momentum solely by building new plants on greenfield sites. They will have to increase the throughput of their existing facilities."

EV battery conveyor solution: scalable, flexible, and pallet-free

In addition to the growing demand for scalability, Intralox has identified two other criteria that will help battery manufacturers separate the wheat from the chaff when searching for the conveyor solution for their next production plant: First and foremost is flexibility, as the number of different battery types will increase dramatically over the next five years. Plants must therefore be able to process a large number of different types on the same intralogistics system. Solutions for tomorrow's production line must be able to handle a wide range of weights, dimensions, and other varying characteristics. The third requirement identified by Costa is a solution without pallets and workpiece carriers. These would only increase the complexity and cost of the production line, as pallets would have to be constantly collected, returned, and checked. Handling batteries directly on the conveyor surface reduces investment costs and time to market.

"The ISC CAM solves many of the problems posed by the classic automation structure."

Lazlo Kleczewski | Product Design Manager | Intralox

Intralox's innovative conveyor technology

Intralox is an innovative company, as evidenced by the more than 1400 patents it holds worldwide. With an inventor as its founder, the company has always focused on developing new solutions in which its patents create added value. This is one reason why Intralox focuses on technologies such as modular plastic belts for special purposes, for example hygienic belts for transporting unpackaged food. Intralox solutions form part of the logistics infrastructure of market leaders in almost all industries.

One example of this inventive spirit is Intralox Activated Roller Belt (ARB) technology, which was introduced 15 years ago. Conventional roller conveyors typically use pop-up ejectors to separate goods or transport them transversely to the conveyor direction. These belts pop up between the rollers and are separately motorized to enable the lateral movement of goods. A disadvantage of this technology is that the belts between the rollers do not support the entire base area of the transported goods and therefore limit the size of the items being transported.

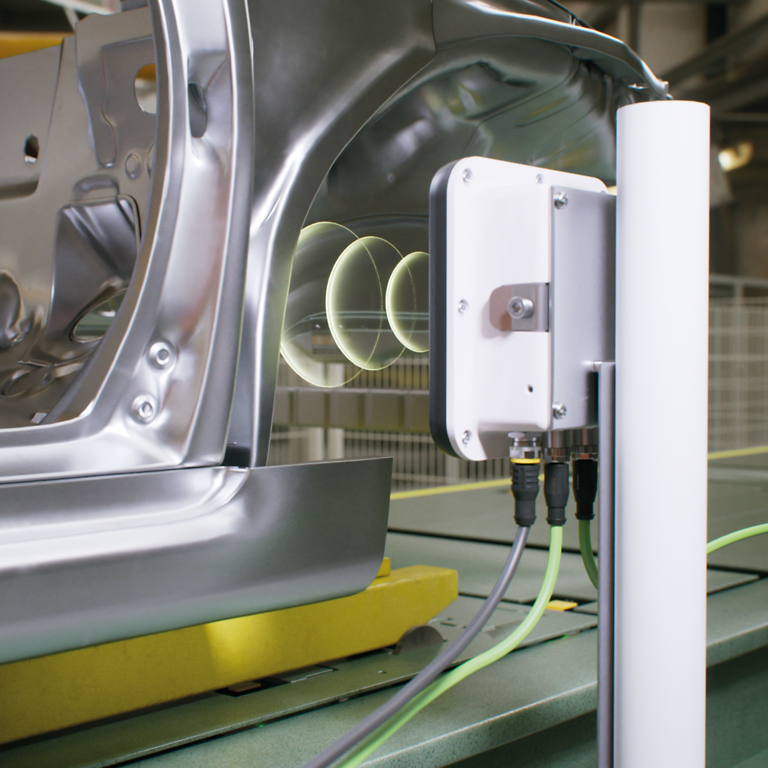

Intralox's ARB technology solves this problem with a belt that has small rollers embedded in it at a specific angle to the direction of travel. ARB devices, and DARB devices in particular, can be the ideal solution, especially when high throughput and careful handling are required during separation. DARB stands for Dual Stacked Angled Roller Belt, a special version of ARB technology that is capable of transporting items up to 90 degrees across the line.

DARB technology perfectly meets the three critical requirements for electric car battery production logistics: scalability, flexibility, and the ability to move batteries without pallets. It improves scalability because it can significantly increase the throughput of battery lines compared to conventional link conveyors, as there are no stop and start times before orthogonal movements. In addition, the conveyor line with

DARB is more flexible because it supports the full range of sizes, eliminating size restrictions for items. The only limitation is the dimensions of the belt itself. Furthermore, smaller parts cannot fall between the rollers as they can with standard roller conveyors. Finally, DARB solutions eliminate the need for pallets because they carry the EV battery across the entire base plate.

"We started with a separate PLC for the DARB systems, but this is not cost-effective as we had to offer different PLCs and build large control cabinets to meet customer requirements and regional regulations. This makes product development and maintenance very complex."

Martin Benavidez | Business Development Analyst | Intralox

Problem: Centralized PLC solutions are not very scalable

Some lithium-ion battery manufacturers are already benefiting from the capabilities of DARB systems in their production, according to Martina Costa. But the company has found further potential for improvement in its search for the optimal conveyor for the growing battery industry. As an OEM (original equipment manufacturer), Intralox does not usually automate the ARB systems itself; this is traditionally done by the integrator of the intralogistics systems in accordance with Intralox guidelines. "We have found that this process is not always efficient, as a lot of expertise is lost in communication. We work with DARB all the time, but the integrator only does so occasionally. This can be challenging for all parties," explains Martin Benavidez, Intralox Product Manager for ISC. The acronym stands for "Intralox Smart Carryway," an innovative program that aims to develop an automation solution for controlling Intralox systems, including the DARB product line. Benavidez is leading the project together with Lazlo Kleczewski as Product Design Manager for ISC.

Integrators often choose to use an existing PLC in the system to control the DARB solution. However, if a PLC controls multiple machines, troubleshooting during commissioning and changes during operation can be time-consuming and risky. To solve this problem for its customers, Intralox expanded its offering to include automation of the DARB system. "We started with a separate PLC for the DARB systems, but this is not cost-effective because we had to offer different PLCs and build large control cabinets to meet customer requirements and regional regulations. This makes product development and maintenance very complex," explains Benavidez. Traditional PLC solutions are difficult to scale because the cost of developing and assembling the control cabinet and maintaining different PLC platforms that have been established in customer factories for years is very high. "Scalability is very important to us. That's why we looked for a solution that would allow us to incorporate our many years of experience and knowledge into a small device that is easy and hassle-free to use," adds Lazlo Kleczewski.

Solution: Decentralized IP67 controllers provide flexibility

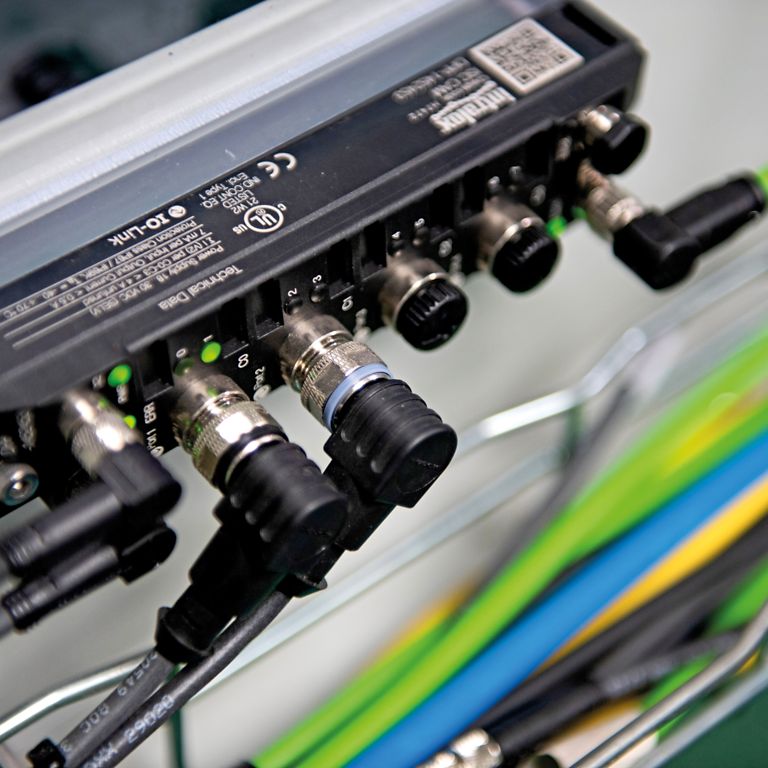

The solution is the Intralox Smart Carryway Controlled by a Carryway Automation Module (ISC CAM), a compact IP67 block module that incorporates Intralox software logic. ISC CAM maximizes the performance of the system without the need for a control cabinet. TURCK's TBEN-S forms the hardware platform for the ISC CAM. Thanks to its multiprotocol capability, the TBEN module can serve a wide range of customers with minimal product variations. TURCK's multiprotocol devices support PROFINET, Modbus TCP and EtherNet/IP and adjust themselves independently to the Ethernet protocol spoken in the network without user intervention. This provides an improvement for everyone involved: The integrator only has to program their PLC to transmit some basic commands, which reduces the effort and risk involved in integrating and commissioning DARB devices. The end user can be sure that the devices are always state of the art and can rely on Intralox support for DARB devices. "The ISC CAM solves many of the problems raised by the classic automation structure," says Kleczewski.

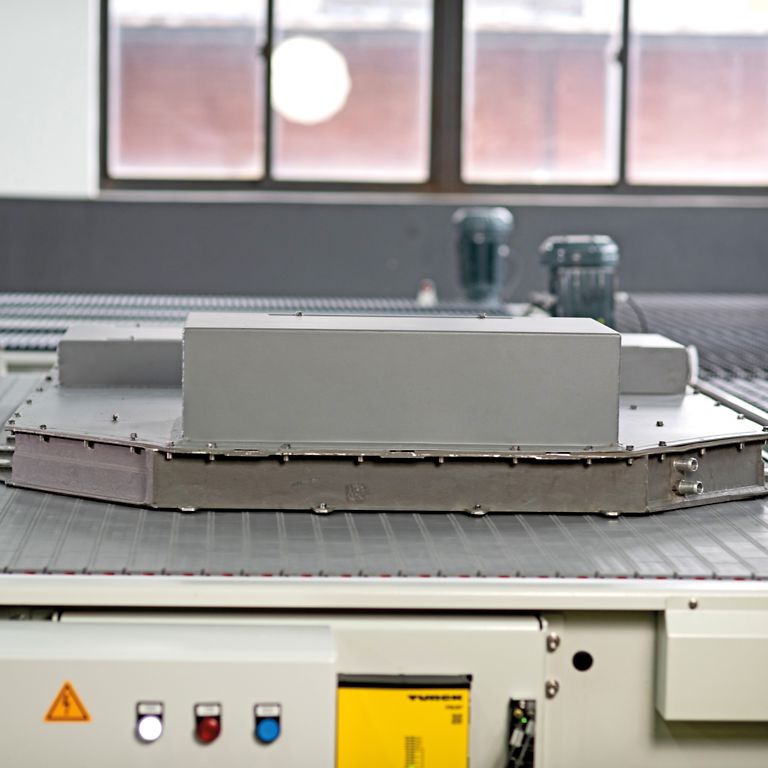

DARB demo plant with decentralized automation

To demonstrate DARB technology as the ideal solution for supporting the EV battery industry, Intralox has set up a demonstration plant in Shanghai, where potential customers can gain a deeper understanding of the technology's capabilities. In addition, the plant demonstrates the advantages of decentralized automation. Each DARB device has its own ISC CAM for automation and other modules for functions such as motor control and safety. The result is a high degree of modularity of both hardware and software, making it easier to set up, troubleshoot, and make changes such as adding or removing a conveyor.

With this demonstration plant, Intralox demonstrates that decentralized automation solves many of the system manufacturers' problems in integrating their products into larger systems. Traditional solutions would require a control cabinet for components that are often not available in high protection classes, such as HMI, motor control, frequency converters, power supplies, or other components. However, the ISC and TURCK's broad portfolio of modular IP67 field components offer solutions for these problems. This enables clean and flexible solutions to be implemented.

TURCK: Comprehensive IP67 portfolio for decentralized automation

The plant's HMI does not have the typical screen on the cabinet. "There is no need for a physical HMI, as the plant can be controlled, set and changed via a virtual HMI hosted on the ISC CAM web server. This is easily accessible with a laptop or any device with a web browser," says Lazlo Kleczewski. The automation of the motors and safety systems is decentralized by a combination of field controllers from the TURCK TBEN family. Thanks to the large portfolio of IP67 I/O components for serial and Ethernet communication, the control cabinet of the demo plant is no bigger than a shoe box. It contains just a few safety components. The ability of TURCK Ethernet solutions to communicate either with PROFINET, EtherNet/IP or Modbus TCP eliminates the need to develop individual solutions for customers in different regions. TURCK's robust PSU67 power supply simplifies the supply of 24 VDC for operating the automation components at the plant.

Intralox's "integrated and holistic design" offers even more benefits to the user: By eliminating the need for a control cabinet, not only are fewer parts required, but cables with loose ends are also avoided, making the systems virtually plug-and-play. The color coding of the connectors ensures a high degree of precision, which minimizes the risk of errors. This makes the cabling of the devices easier and more intuitive and makes it almost impossible to connect them incorrectly. "We are trying to show that it is possible to design these complex systems simply and intuitively. All you have to do is think a little differently," the ISC team summarizes.

Customer | www.intralox.com

Frank de Jong is Marketing Manager at Turck B.V. in the Netherlands