Tracking of battery raw materials

RFID system from a single-source ensures reliable processes via OPC UA — even at high throughput and in complex applications with high variability

Benefits

- No interface conflicts, since the solution comes from a single source

- OPC UA integration for seamless data transfer from the field level to the ERP system

- Ready for future cloud implementations via OPC UA

- High availability thanks to an end-to-end IP67 solution

Challenge

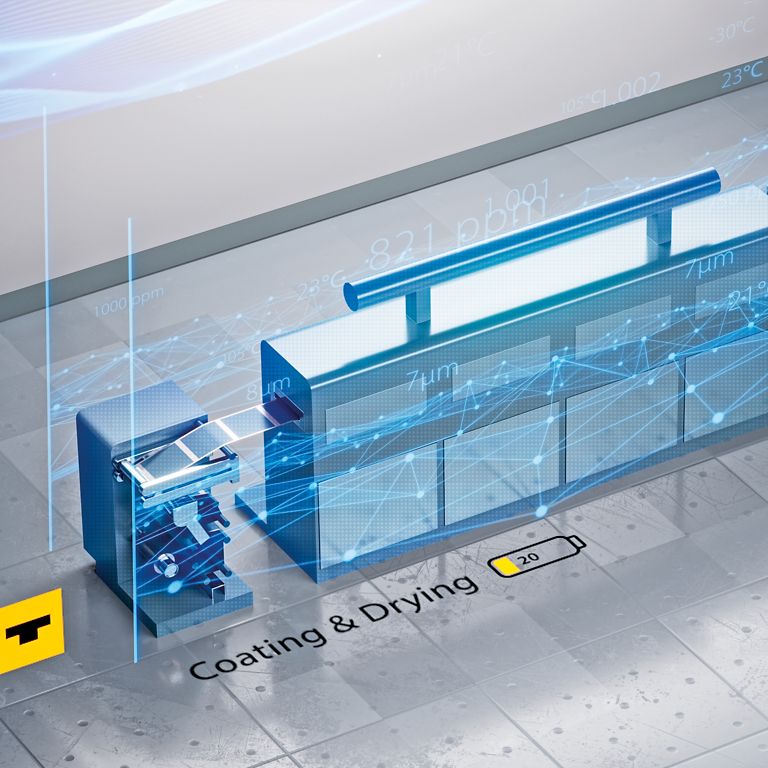

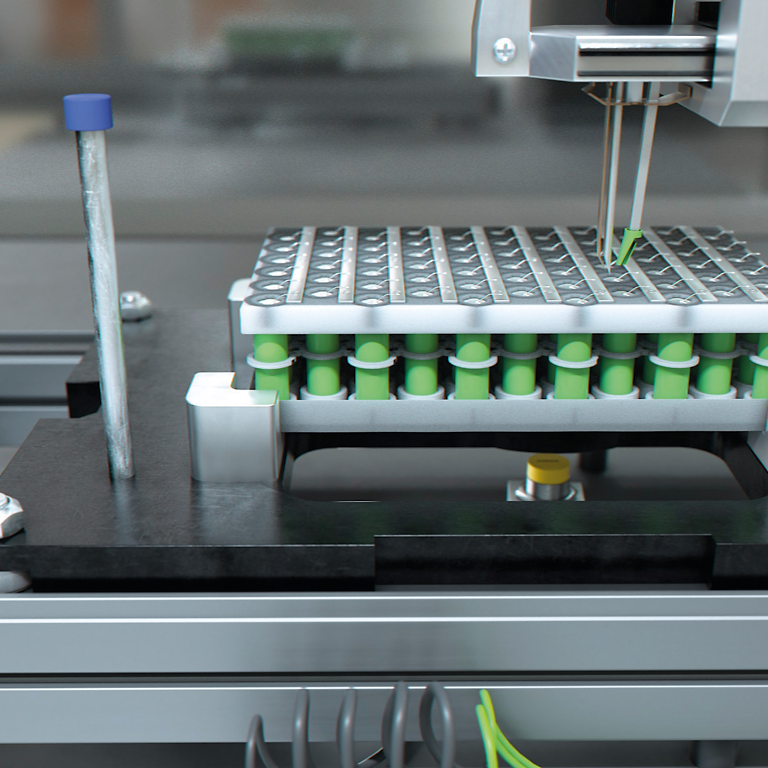

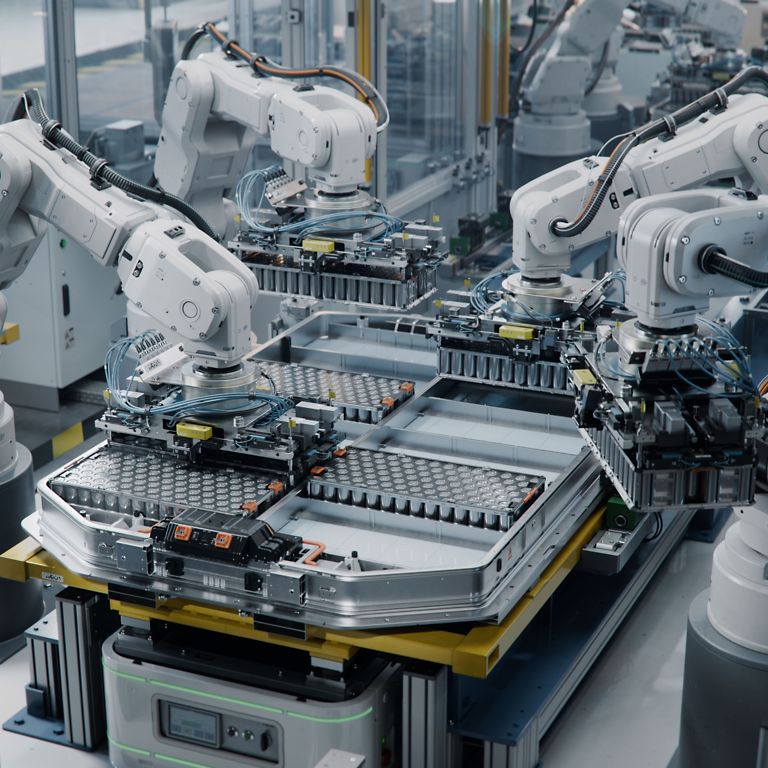

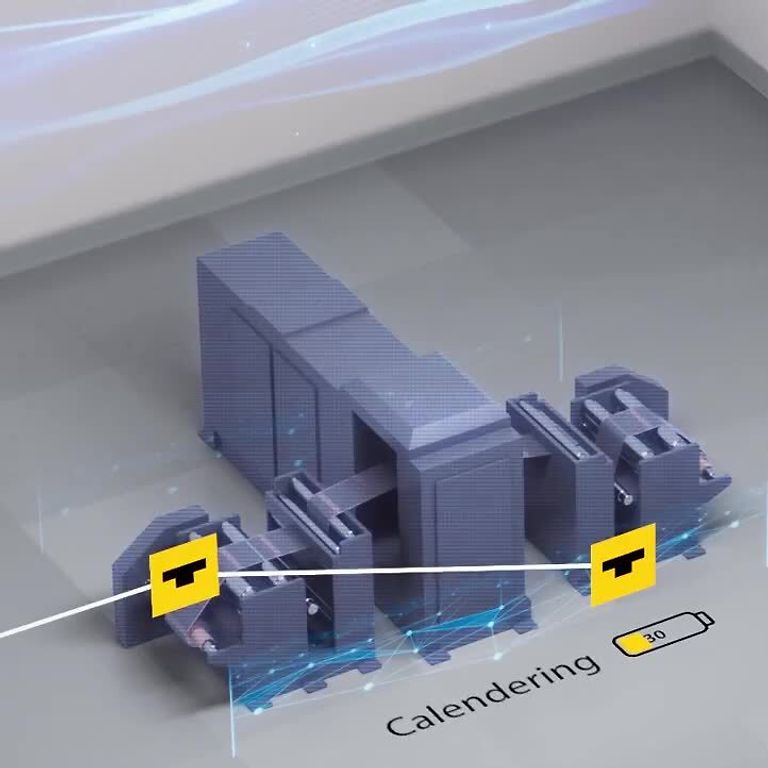

In battery cell production, different raw materials must be processed in the correct order and with precise parameters. Incorrect material assignments or incorrect process steps can impair the quality of the cells. Reliable identification of the material containers is necessary to ensure error-free operation and to document the production steps performed without gaps.

Solution

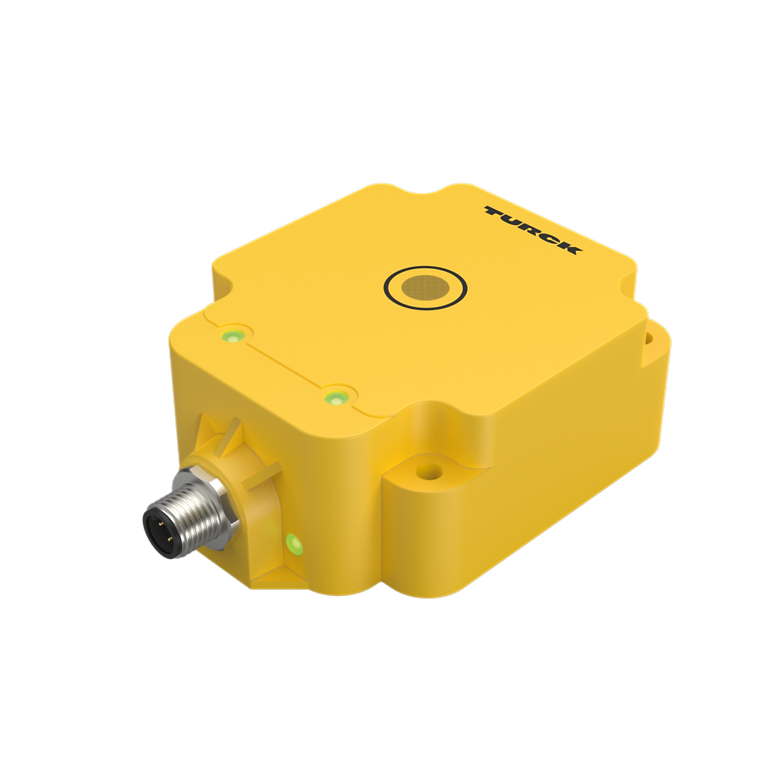

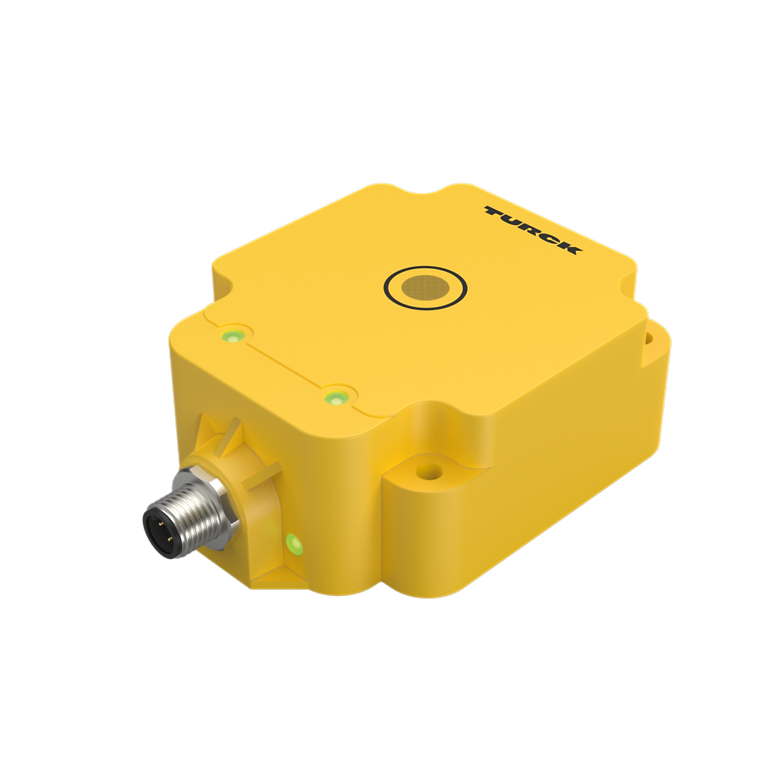

TURCK's RFID system enables automated identification of containers holding raw materials. Read/write heads such as the TNLR-Q80 are specially designed for harsh environments with dust and chemical influences. They capture RFID data contact-free and transfer it directly to the ERP system via the TBEN-L-4RFID interface using OPC UA. This direct communication with the IT level enables seamless integration into existing production processes.

Standard RFID systems are often prone to errors, especially in metallic environments. TURCK offers special high-frequency tags for this purpose, which can be reliably read even on metal. The system simply reads the ID of the container and adds all relevant production data from a central database. This solution minimizes production errors, optimizes processes and ensures complete traceability.

"With our robust RFID technology and the OPC UA interface, we provide an end-to-end solution for material tracking in battery cell production."

Chien-Hsun (Josh) Chuang | Sales Director Greater China | TURCK GmbH

Erfahren Sie mehr über unsere Produkte