Monitoring of battery production

The complete IO-Link solution guarantees production quality by monitoring roll pressure, roll temperature, and roll diameter during the calendering of electrodes

Benefits

- Comprehensive status monitoring through flexible output signals

- Simple configuration and efficient wiring via the uniform IO-Link standard

- Reliable data export thanks to globally standardized point-to-point communication protocol

- Precise pressure measurement with diagnostic options

Challenge

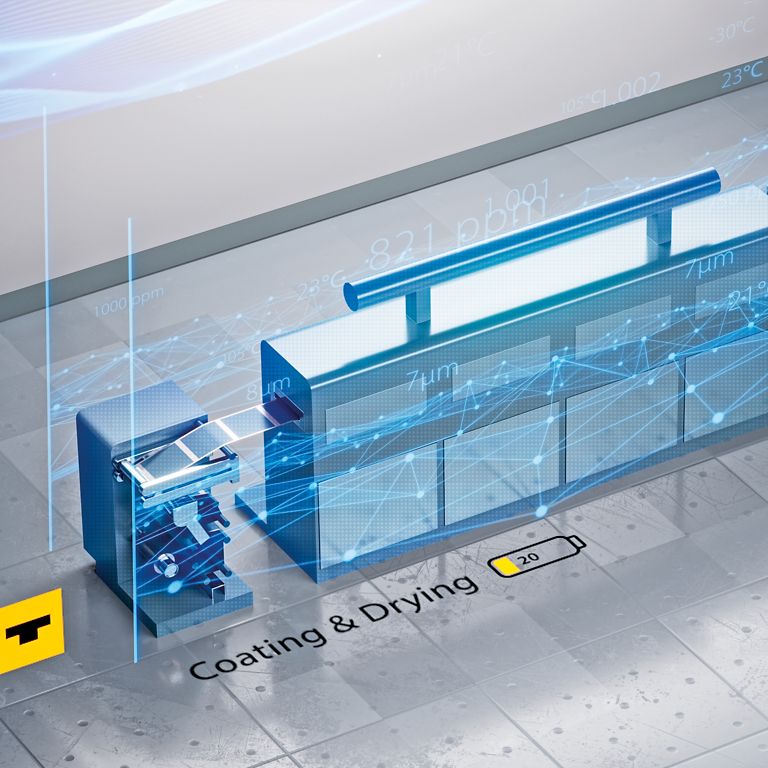

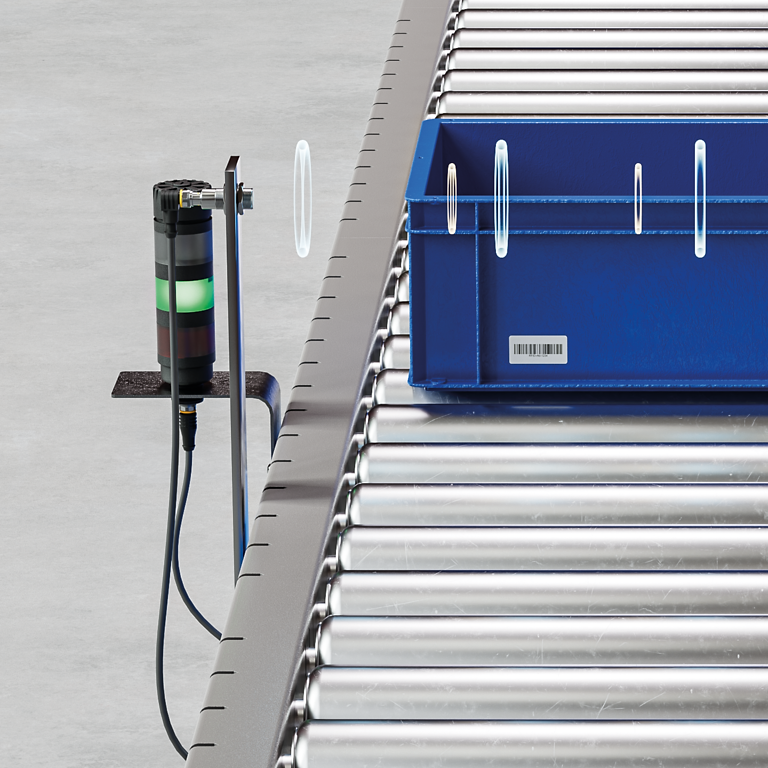

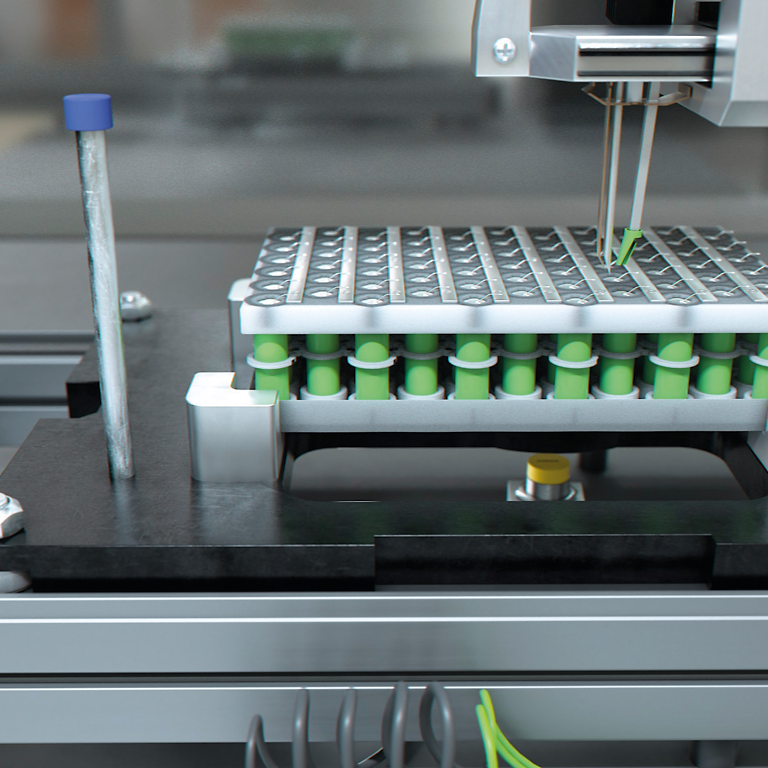

When calendering electrodes for lithium-ion batteries, the coated metal foil is compacted with high precision. Deviations in pressure or temperature significantly impair cell quality. Excessive pressure can damage the material, while insufficient pressure prevents the electrodes from achieving the desired density and porosity. In addition, empty rolls must be detected in good time to avoid unplanned downtime.

Solution

TURCK's complete IO-Link solution ensures optimal calendering by monitoring all critical parameters in real time. The TBEN-L4-8IOL multi-protocol I/O module with eight IO-Link master channels serves as the central interface. It collects data from PS+ pressure sensors, which ensure constant pressure for the compression of the electrode foil. TS+ temperature sensors monitor both the roller temperature and the heating fluid to ensure uniform heating. To avoid production stoppages, the RU80D ultrasonic sensor continuously measures the diameter of the rolls and detects in good time when a new roll needs to be inserted. Thanks to IO-Link, all sensors can be easily parameterized and quickly replaced if necessary. In addition, the sensors provide additional diagnostic data that can be used for preventive maintenance and process optimization. TURCK's solution thus enables consistently high quality of battery cells while reducing downtime and maintenance costs.

"Manufacturers retain full control of critical calendering processes thanks to our complete IO-Link solution. They benefit from precise measurement values, easy integration and maximum process reliability."

Chien-Hsun (Josh) Chuang | Sales Director Greater China | TURCK GmbH