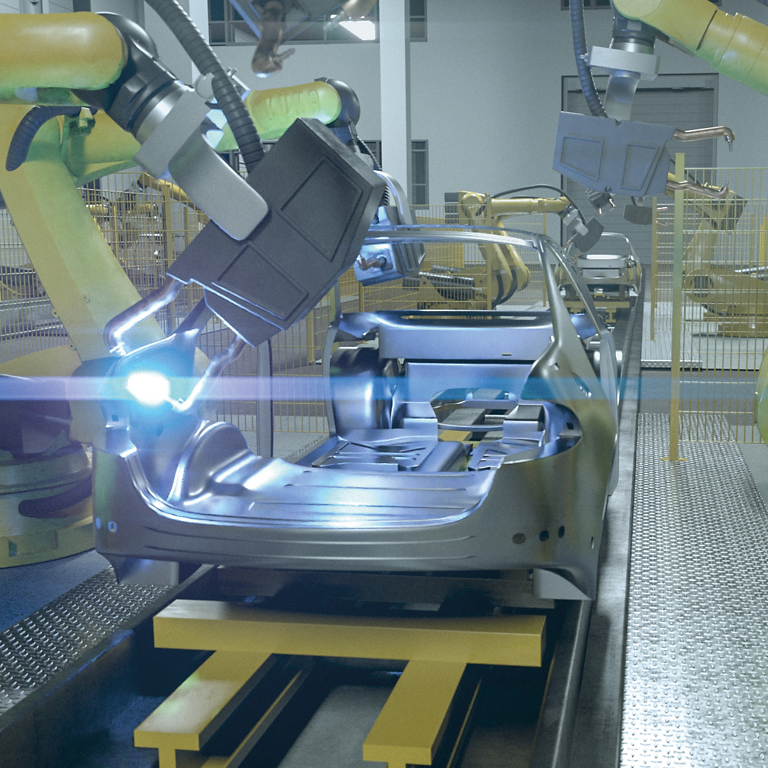

Cooling circuit monitoring on welding guns

FS+ flow sensors monitor the flow of coolant and provide warnings in the event of critical temperature changes

Benefits

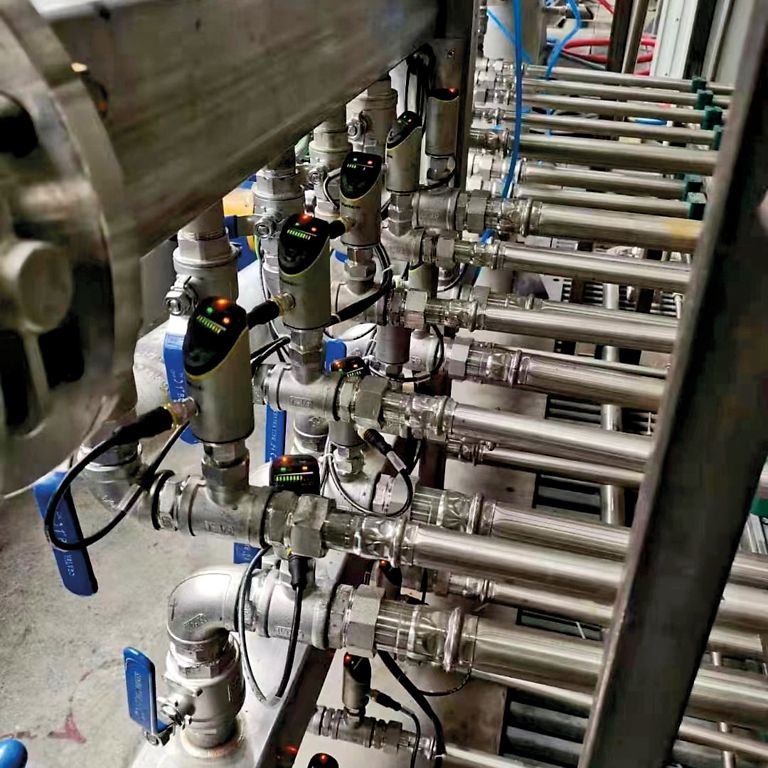

Reduced downtime thanks to reliable monitoring of flow and temperature

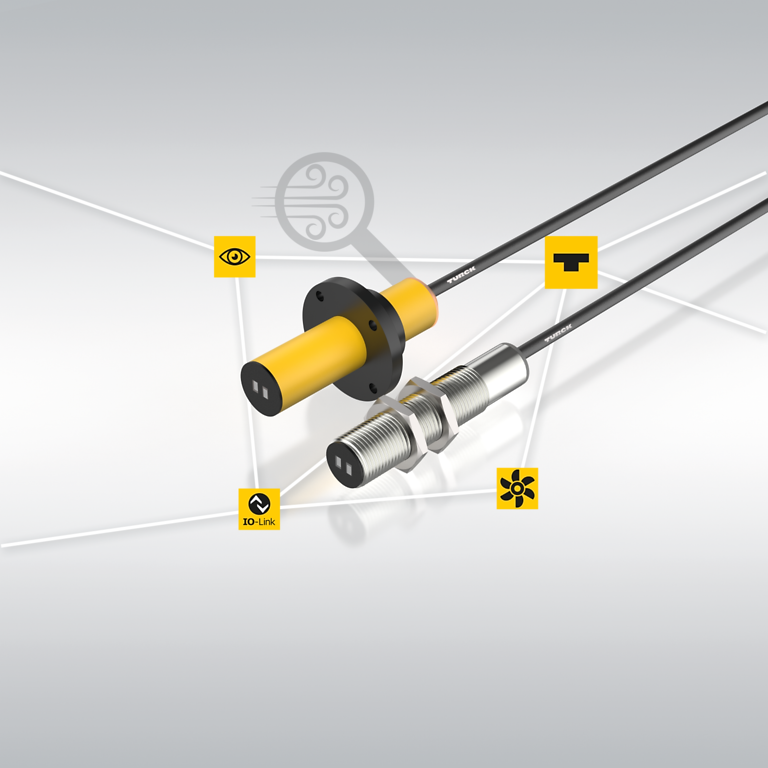

Utilize the benefits of IO-Link: flexible device integration and end-to-end communication down to the sensor level

Intuitive operation via touchpads with smartphone-like haptics

Challenge

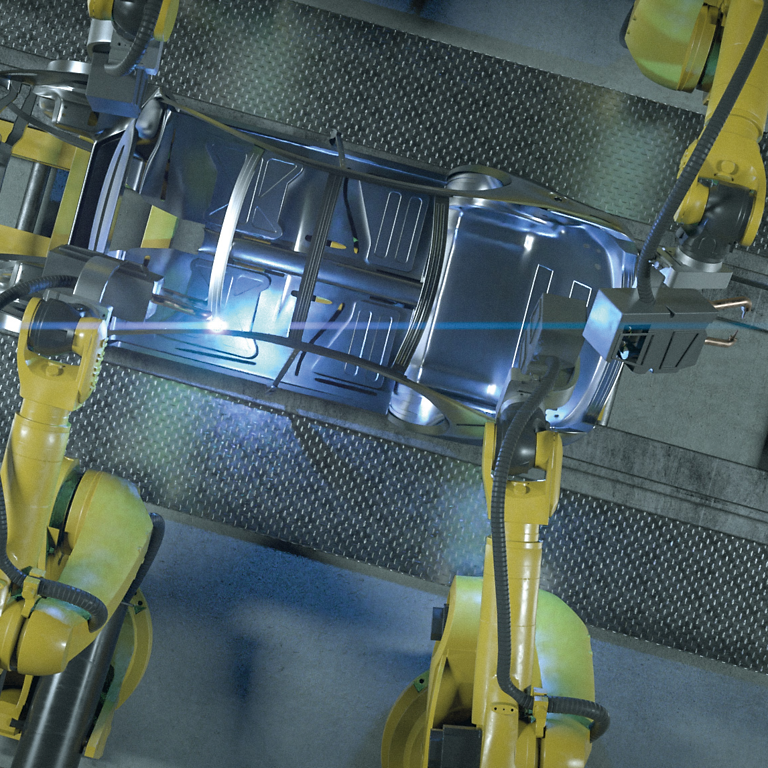

Monitoring the cooling circuits of welding guns is essential to prevent overheating and to ensure consistent weld quality. During spot welding of body components in automotive production, high temperatures are generated, requiring reliable cooling of the welding guns. Overheating can cause the welding tip to fuse to the welded component and break. A reliable solution is required to help prevent quality defects, wear or even downtime.

Solution

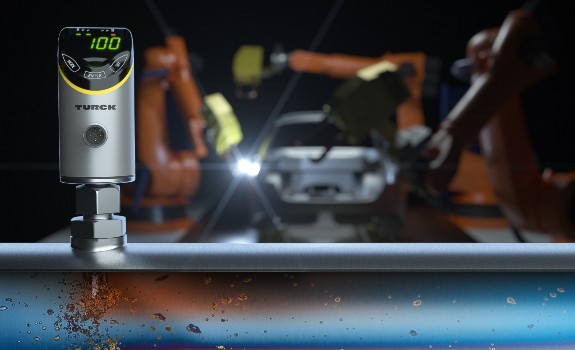

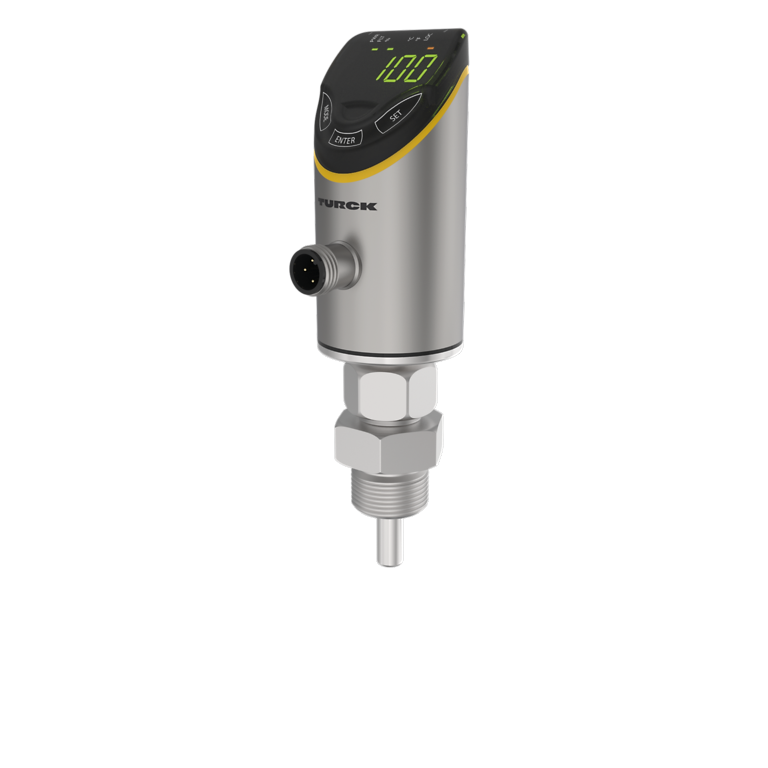

The FS+ flow sensor from TURCK monitors both the flow rate and the temperature of the cooling medium, providing dual safety. Thanks to its calorimetric measuring principle, no additional temperature sensor is required. The 4-digit alphanumeric display can show either the flow rate or the temperature of the medium, allowing operators to assess the condition of the cooling circuit at a glance. A color-coded LED display provides a clear visual representation of process values. The Auto Detection function automatically identifies whether a PNP or NPN signal is required. Using Max/Min-Teach, the upper and lower limits of the flow detection range can be easily set, making it easier to analyze fluctuations in the cooling circuit. With Quick-Teach, the current flow velocity can be set as the switching point within a few seconds. Delta flow monitoring prevents incorrect settings and thus ensures reliable commissioning. In addition, the IO-Link 1.1 interface enables efficient integration, remote maintenance and predictive maintenance.

"With FS+ flow sensors, users are able to monitor two variables: they track not only coolant flow but also temperature. This enables overheating to be detected early and prevents failures."

Vinesh John | Product Manager Fluid Sensors | TURCK GmbH