Battery Production

Automation solutions for battery production: robust, data-based, reliable

Automation power for dynamic battery production

How can battery production be set up in a highly efficient and flexible and scalable way?

With smart sensors whose data gives you a glimpse into the future. Open standards and decentralized I/O and control systems facilitate expansions and conversions — and create the basis for flexible, scalable, and future-proof production.

Solutions for battery production

See the advantages that TURCK solutions offer in battery production: data-driven and digitally networked for maximum availability and smart processes.

Find your solutions

Automation solutions and products from TURCK increase the availability and efficiency of your machines and systems in numerous industries.

Insights for battery production

Discover relevant content for your industry, from trends and best practices to efficient automation approaches and innovative technologies that make processes more transparent, flexible, and secure.

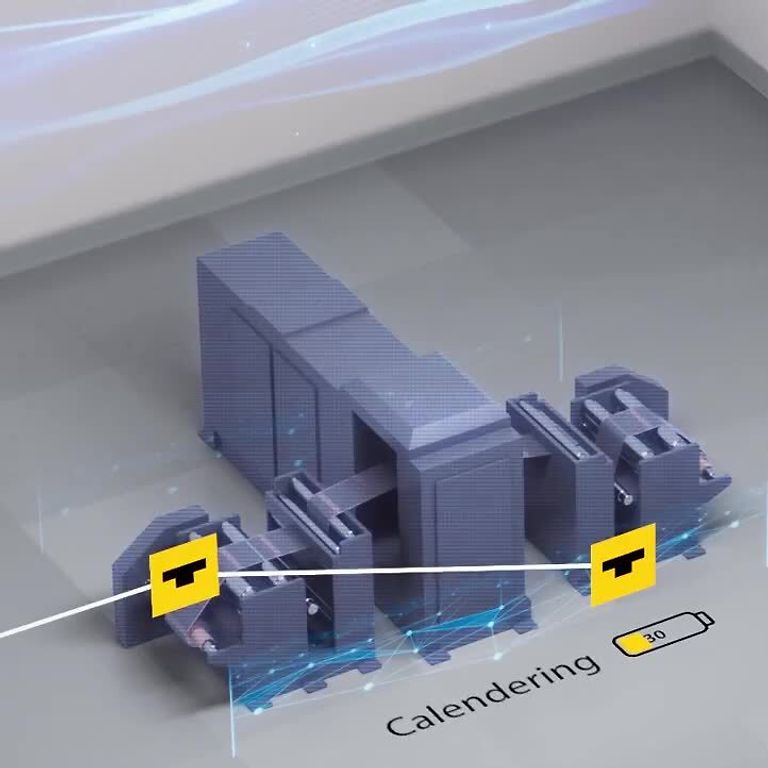

The bus is coming

TURCK's RFID bus mode is the most efficient solution for many read/write points. Automatic address assignment shortens commissioning time.

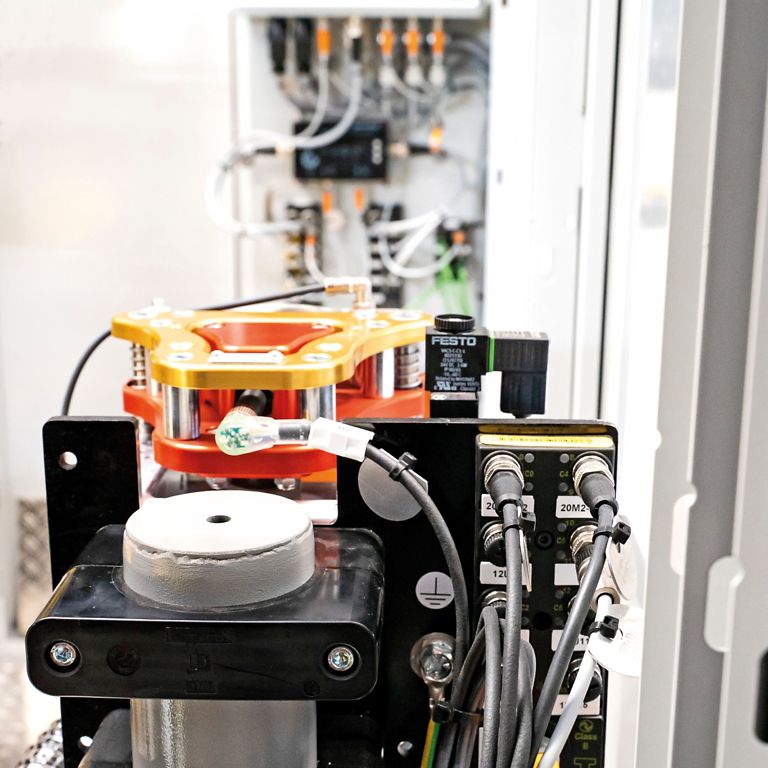

Decentralized I/O modules control conveyor technology in battery production

EV battery manufacturers require easily scalable conveyor technology solutions. To enable smart control of variable systems, Intralox developed the decentralized logic module ISC CAM with robust TURCK block I/Os

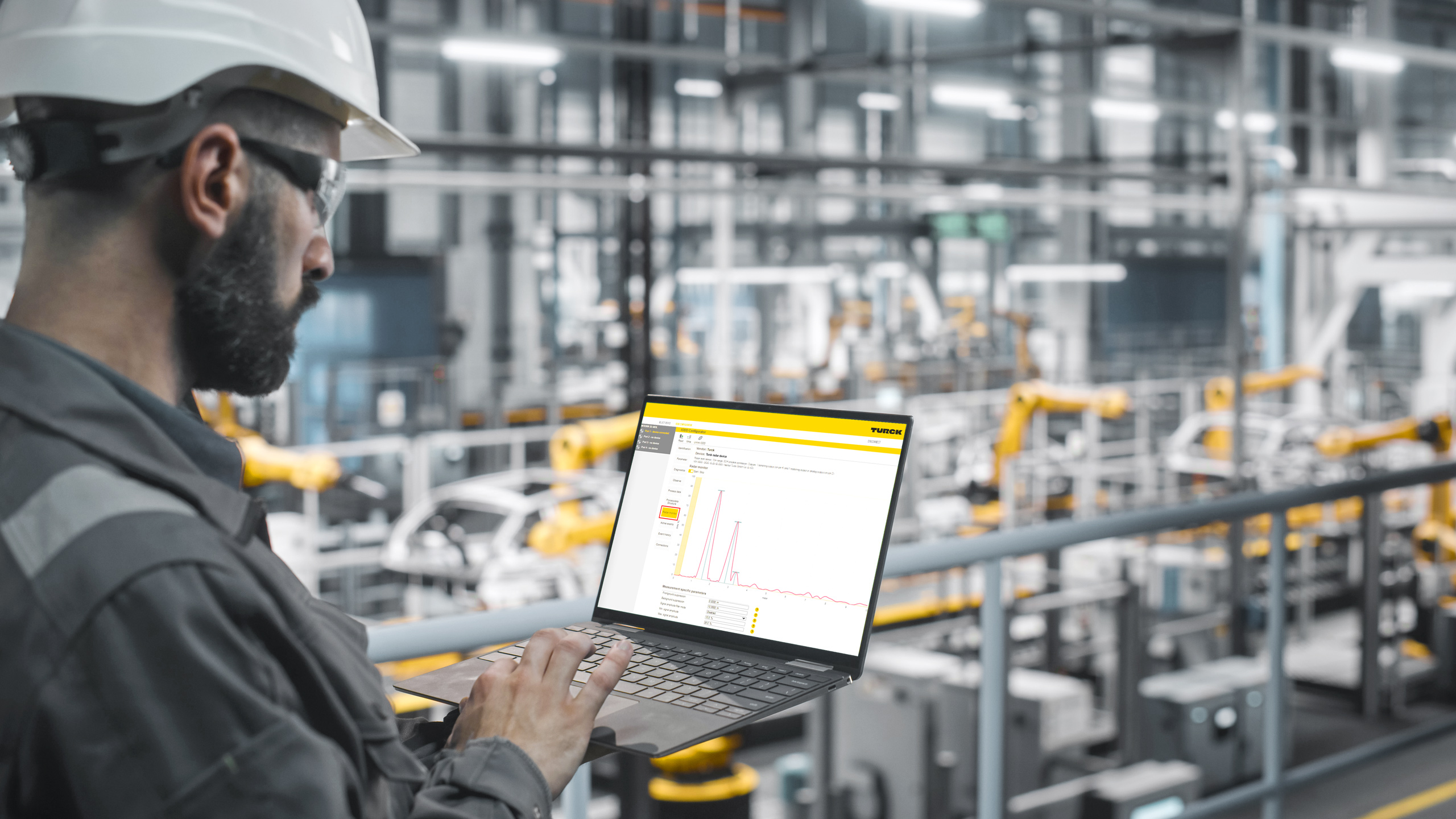

TAS — software for IIoT and more

The TURCK Automation Suite is a complete IIoT solution for updates, device management and condition monitoring. Learn how TAS simplifies and accelerates commissioning and network management.

Data-driven battery production

Digitalize your battery production and benefit from greater resilience, flexibility and ROI.

Fast turnaround times

High-speed data communication, decentralized signal processing and control plus identification with RFID ensure a highly efficient flow of materials.

Efficient data integration

Sensor and I/O solutions with IO-Link supply valuable data for condition monitoring and predictive maintenance.

End-to-end traceable production

RFID and sensor technology create transparency from the raw material through to delivery.