RFID tracking for transparent processes in production and logistics

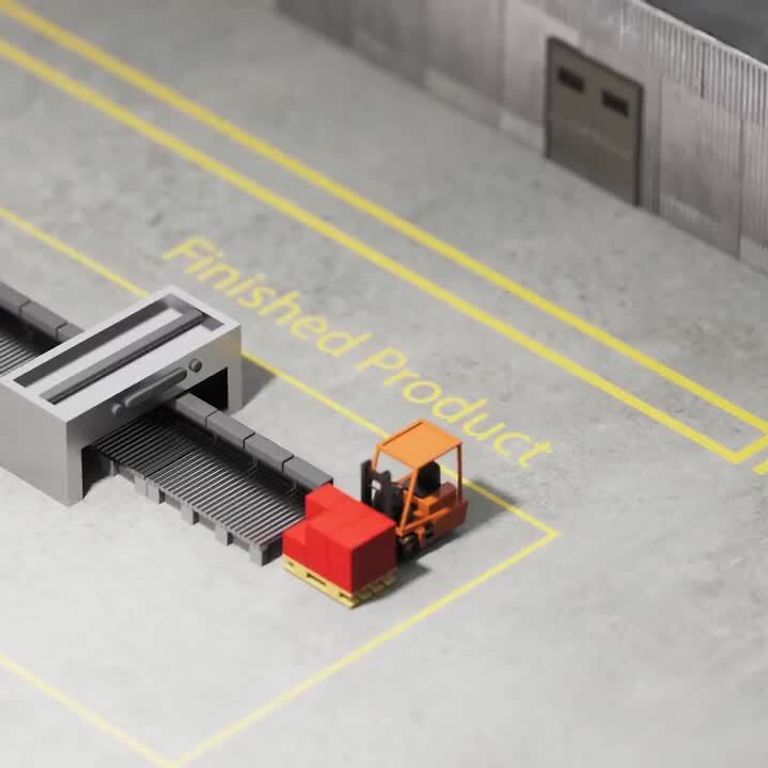

RFID makes processes in production and logistics highly transparent, from incoming goods to production and storage to dispatch – an ideal solution for efficient management of reusable containers (RTI)

Quick read

Reusable containers such as pallets, crates or plastic crates are the load-carrying items of many production and logistics chains. If the movements and positions of the reusable containers are not continuously recorded, the logistics systems are not transparent. The result is high costs due to the build-up of spare and buffer stocks as well as expensive transports. The use of RFID technology ensures the efficient management of an RTI pool throughout the entire production process chain. A holistic tracking concept improves visibility and control in load carrier management and thus creates added value in production logistics that increases pool transparency and minimizes waste and loss.

Complex structures, opaque processes, and high cost pressures pose the same challenge to companies in the manufacturing and logistics industries: to remain competitive, fast decisions based on real-time information are becoming increasingly crucial.

RFID systems are today the means of choice for generating information relevant to decision-making. They bridge the gap between the physical production world (Operational Technology, OT) and IT-based MES and ERP systems. By linking the objects with the data of the IT systems, RFID systems generate the necessary transparency for lean processes and digitalized supply chains. The aggregated information, for example about times, locations, users or completed process steps, enables smart functions such as automatic production and ordering processes, the identification of sources of error or the timely prediction of any bottlenecks. RFID information enables systems and decision makers to draw the right conclusions.

Transparency from goods receipt to dispatch

With RFID-based information, countless processes in production and logistics gain greater transparency, from incoming goods to production and storage to dispatch. Returnable Transport Items (RTI) play a major role here, i.e. reusable containers such as pallets, lattice boxes, plastic boxes or metal trays. Reusable containers are a crucial factor in ensuring the quality of production processes.

RFID-based container management ensures that reusable containers are always in the right place at the right time in the right quantity and quality. The costs for an RFID system are paid off very quickly due to the enormous savings, as no more missing containers need to be procured at short notice and made available at the place of use.

Advantages over barcodes

When identifying RTIs, RFID offers decisive advantages over comparable technologies, especially compared to barcodes. There are hardly any restrictions when using RFID-based systems, as there are suitable RFID tags for almost all cases and ambient conditions. In addition, in an RFID-based system, the reading of large quantities can be easily automated without slow and error-prone manual steps.

To ensure smooth, RFID-based container management, special management tools provide the option of displaying all RTI information on one platform. This closes the gap between the physical production environment and IT-based MES and ERP systems. By linking objects with data from IT systems, RFID systems create the necessary transparency for lean processes and digitalized supply chains. This information allows both systems and decision makers to draw more informed conclusions, resulting in increased efficiency in RTI management and a high degree of adaptability to seemingly unpredictable events in the RTI cycle.

Efficient container management saves costs

It is obvious that reusable containers should not be treated as disposable items. Only efficient pool management makes reusable containers a powerful tool for building sustainable supply chains. Shrinkage, damage or inefficient management often results in additional reusable containers being procured to avoid bottlenecks and downtime, so that the actual total stock exceeds the optimal quantity. Often no one knows exactly how many reusable containers are in use throughout the entire process chain.

Therefore, it is of great importance to keep the number of reusable containers in circulation as low as possible in order to tie up as little capital as possible. At the same time, however, they must be available in sufficient numbers to avoid interruptions in the supply chain. In the worst case scenario, the just-in-sequence or just-in-time line could come to a standstill because reusable containers are not available or not in sufficient quantity where they are needed.

Tracking on the RTI

Given the large and constantly changing nature of the investment in reusable containers, it is essential to efficiently monitor and control it to match supply and demand. The seamless tracking requires the clear identification of each container as well as real-time communication with all parties involved within the cycle.

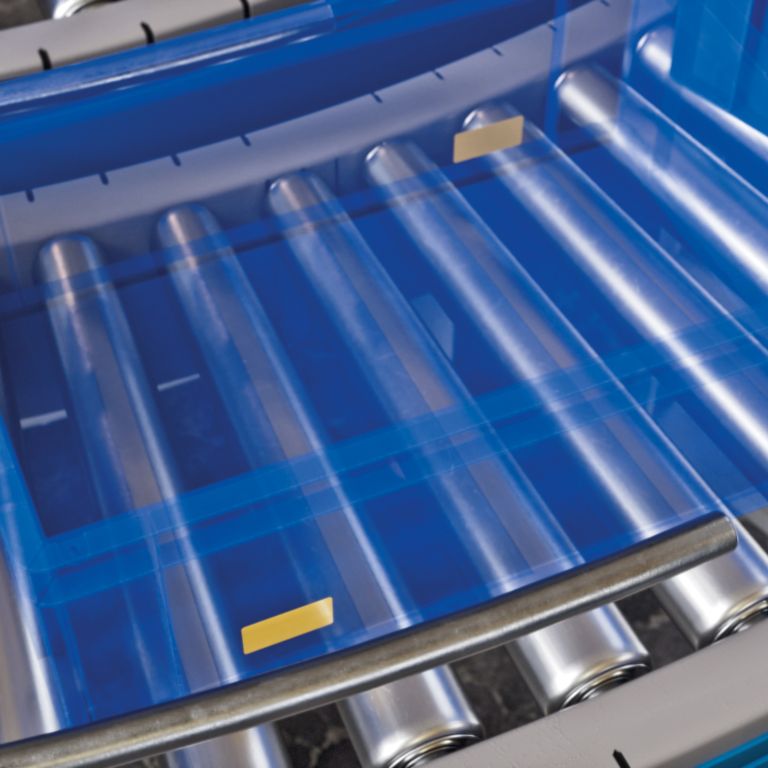

To do this, it may be useful to record several containers at once. If, for example, several containers with RFID tags are located on a pallet, multi-tag reading is required, i.e. the simultaneous reading of several RFID tags. This is usually done via RFID gates that are equipped with several antennas and thus reliably detect the tags without the need for direct visual contact.

Selecting the right reusable container type is also an important task. The container sizes range from shoe boxes to pallets for larger goods. They should be reliable, sustainable and durable. However, each industry also has its own requirements for reusable containers. Accordingly, the variability is very large. To ensure seamless tracking of reusable containers, it must be possible to detect all container types using RFID. It is therefore important that the RFID tags used are consistent and reliably legible on all surfaces – for example, on plastic, metal and ESD materials (ElectroStatic Discharge) as well as on folded reusable containers.

The choice of the appropriate RFID tag is essential for the architecture of an RFID solution and depends on the respective application. If the selected tags are unsuitable for the application, not sufficiently robust or powerful, the read rate of the RFID system will be too low and the entire system may fail. It is therefore necessary to understand the technical requirements and requirements of the respective process in as much detail as possible.

RFID Turnkey Solutions

In addition to the RFID tags that can be attached to or embedded in the identified RTI, a turnkey RFID solution typically consists of RFID read points and their antennas, RFID server applications for data evaluation, system monitoring and maintenance, including an integration layer to support the most common business systems such as ERP and WMS, integration into the customer's back-end system and an implementation plan.

Through its subsidiary Turck Vilant Systems TVS, TURCK can cover the complete range for turnkey RFID solutions. For 20 years, TVS has been designing and implementing turnkey RFID system solutions including its own middleware and ERP integration for intralogistics, asset tracking and inventory management. Combined with TURCK's many years of experience with RFID for production control, both companies offer joint complete solutions that map the entire supply and production chain – from suppliers to production and delivery.

Five phases to success

An RFID project with Turck Vilant Systems is divided into five phases. In the first phase of the project, the aim is to develop an understanding of customer needs and to familiarize the customer with RFID. The starting point for customer engagement is the site survey to obtain an expert analysis of the customer's plans and processes. Based on the site survey, the expert makes a suggestion as to how RFID technology can be used and where the ROI could lie. These services are free of charge for the customer.

In the second phase, specific RFID feasibility studies will be carried out. For customers without experience with RFID, this starts with a proof of concept. This means that the RFID equipment is tested on site at the customer's site to ensure that tags, readers, or applications work in the intended application.

In the third phase, everything is prepared for the roll-out in a pilot project. The RFID system is tested on a production line or system before it is put into operation throughout the entire area. The customer using the system can help to identify sources of error that may not have been considered before.

The rollout and commissioning will take place in the fourth phase. The customer installs the RFID readers, with a Turck Vilant Systems technician on site to set up the software and ensure everything works. All processes are tested live and customer staff are trained in English, French, German, Swedish or Finnish.

As soon as the system is ready for operation, the fifth phase begins: support. Continuous system operation must be ensured around the clock – including on public holidays. Turck Vilant Systems meets these customer expectations and provides worldwide service and support 24 hours a day, seven days a week.

Author | Bernd Wieseler is Head of RFID Product Management at TURCK

Turnkey track-and-trace solutions

Turck Vilant Systems (TVS) is the specialist for turnkey identification and localization solutions within the TURCK Group — serving logistics and intralogistics applications worldwide and across all industries. From initial consulting and process analysis to go‑live and productive operation, the team supports every project end‑to‑end. With deep process expertise and proven in‑house software for data pre‑processing, TVS delivers tailored track‑and‑trace solutions with short implementation times, high operational reliability, and minimal development effort.