Reliable identification of liquids

With its Shipment Verification Station, Turck Vilant Systems demonstrated in a proof of concept for Merck that containers holding liquids and metal objects can also be captured reliably and quickly using UHF RFID bulk reading.

Quick read

Reliably capturing multiple RFID tags on a pallet is challenging – especially when the load includes different objects and liquids. Initial tests at Merck in Darmstadt to verify shipments using conventional RFID UHF gates showed that not all substances could be read quickly and reliably enough. The UHF RFID experts at Turck Vilant Systems took on the challenge and, with their Shipment Verification Station, demonstrated that ethanol containers and randomly oriented tags can also be identified reliably and quickly.

If UHF RFID technology is Superman, then water and metal are its kryptonite. Metal blocks and reflects electromagnetic waves, while water absorbs them – both of which prevent reliable read/write processes with passive UHF tags. Merck wanted to determine whether UHF technology could nevertheless be used at its Darmstadt site to verify palletized shipments. The company, known in particular for research-intensive pharmaceuticals, generates revenue in the Healthcare, Life Science and Performance Materials business sectors. Especially in the Performance Materials sector, Merck researches and develops products and solutions for which the company is less well known – but which are present in most households. Liquid crystals or OLED materials for various types of displays, effect pigments for coatings and cosmetics or materials for the semiconductor industry are developed in this business area.

As a result, Merck has benefited for years from the global megatrend of digitalization. As part of digitizing its own processes, the team in Darmstadt asked how far the capture and verification of deliveries could be automated. In logistics, RFID has long been hard to avoid when tackling this question. For longer read ranges and simultaneous capture of multiple tags (known as bulk reading) UHF technology is the only option. However, this technology can be problematic with liquids and metals. At Merck, both liquid materials and metal containers (e.g., drums) play an important role. Therefore, the company first had to build a solid data foundation that could be used to decide whether bulk reads with UHF RFID could even be used to verify its specific goods and intermediate products.

Yanick Luca Kleppinger, who at the time was working for Merck as an undergraduate thesis student, investigated

the influence of different solvents on bulk capture using UHF RFID technology in his bachelor’s thesis. As part of this work, Kleppinger also conducted a proof of concept to assess how well different chemicals and containers can be identified using UHF RFID. In the test setup for this feasibility study, he evaluated the technology using seven pallets that represented the range of container types and substances handled at Merck.

“Through the proof of concept we conducted with Turck Vilant Systems, we know that even difficult products can be captured reliably and consistently with the right method.”

Yanick Kleppinger | Merck KGaA

Range of substances and containers tested

The first three test pallets consisted of cartons filled with glass bottles. The bottles on the first pallet were filled with ethanol, while those on the other two contained different solvents. Pallet four carried plastic ethanol containers; pallet five held two metal drums with a capacity of 200 liters each. Pallet six was loaded with eight smaller metal drums. On pallet seven, Kleppinger tested various containers with powders, bottles, plastic items and metal drums. This mixed pallet was intended, among other things, to verify whether read results would remain reliable when the orientation of the UHF tags resulted randomly from optimized packing processes. Tests with a conventional RFID gate showed promise. However, differences emerged when capturing the ethanol pallets compared with pallets containing other solvents. In particular, tags located on the inside of the ethanol containers could not be captured reliably. The mixed pallet also posed challenges for the conventional RFID gate.

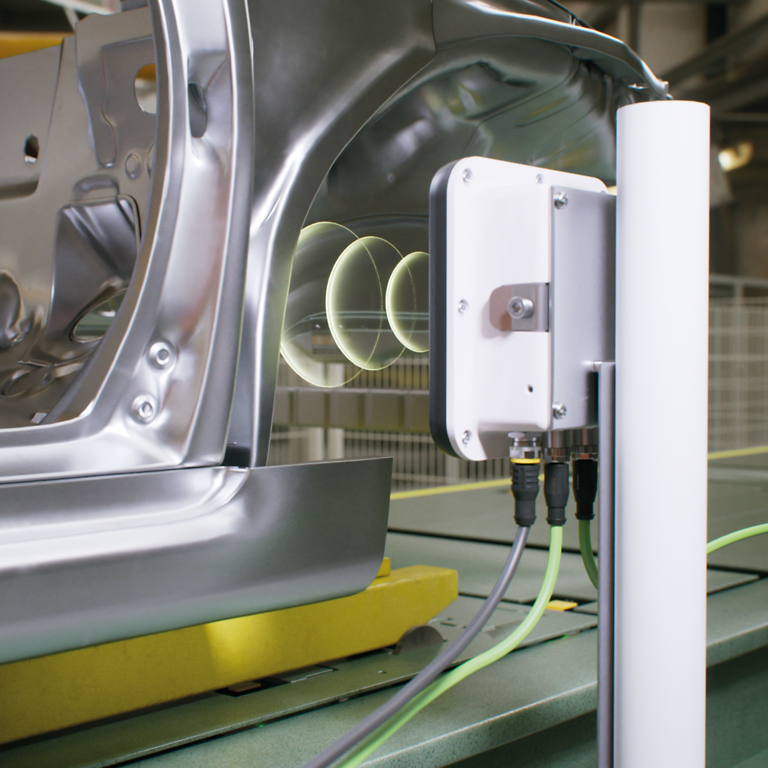

Shipment verification station uses wave reflections off metal walls

Involving RFID integration specialists from Turck Vilant Systems (TVS) provided the solution: the TURCK subsidiary has 20 years of experience integrating UHF solutions across a wide range of industries. In addition to its own RFID middleware, TVS uses the hardware best suited to each application. “Detecting pallets with liquids in an RFID gate is not possible with a conventional gate design,” recalls Robert Paulus, Business Development Manager at TVS, who oversaw the proof of concept at Merck. The tags located on the inside were surrounded by liquids on all sides. Because ethanol absorbs the waves, the tags on the inside are not detected. “In applications like these, we’ve had good experience with our Shipment Verification Station (SVS),” says Paulus. The SVS is a metal enclosure whose three walls and ceiling are equipped with UHF read/write heads. The pallet with the objects to be identified is pushed in through the remaining opening. “In the SVS, we take advantage of the way the waves reflect off the metal walls; the effect can be compared to a hall of mirrors. The electromagnetic waves are reflected again and again, allowing them to reach points on a pallet that conventional RFID gates can’t.”

Polarity decisive for readability

Tests with the first three pallets showed that the three solvents reacted differently to ultra-high-frequency waves. While capturing the 120 tags on the pallet with ethanol bottles took up to 30 seconds, the bottles containing other solvents could be read within two seconds. The tags on the bottles were read almost as quickly as those on the cartons, meaning the difference had to lie in the properties of the solvents themselves. Until then, the literature had only noted that liquids have an attenuating effect on electromagnetic waves. Although the three liquids had similar viscosity, they differed significantly in their damping characteristics. Kleppinger therefore looked for another molecular property that distinguished the three solvents. According to the results of his investigation, the decisive factor was the polarity of the substances; if this finding is confirmed by further tests, it would establish a new state of research on how liquids affect readability with UHF RFID.

Tag selection and positioning are critical

In addition to the factors mentioned above, successful read results also depend on selecting the right tag. Turck Vilant Systems supported this selection, as well as determining the optimal positioning of the tags on bottles, drums or cartons. In the test involving the fourth pallet with ethanol containers made of plastic, the key to good read results was placing the tags above the ethanol fill level. This allowed all 21 tags to be read within two seconds. In addition, the tags must not be obscured by metallic objects.

“On-metal tags” use metal as an antenna

When testing tags on metal drums, the position of the tags was less critical. Special “on-metal” tags were used that utilize the metal drum as an extension of their antenna. All nine tags on the pallet were read within two seconds. The test with eleven smaller drums confirmed this result. In general, for all read operations, the tags should be oriented as uniformly as possible in the same direction.

Mixed pallet with non-oriented tags

On the mixed pallet loaded with drums, plastic containers, cartons and bottles, consistent tag orientation could not be ensured. Small plastic items that are automatically packed into cartons end up scattered in all directions inside the boxes. Nevertheless, the SVS read results were fully sufficient and suitable for the process. All 82 tags were detected within two seconds, despite the arbitrary orientation of the tags.

Proof of concept successfully completed

“After our initial test setups and the insights we gained from them, we were very skeptical about being able to record certain products,” says Kleppinger. “Through the proof of concept we carried out with Turck Vilant Systems, we now know that even difficult products can be recorded reliably and consistently with the right method.”

With a read system such as the Shipment Verification Station, the tested pallets containing all the substances examined can be used reliably at Merck for shipment verification in logistics processes, with very good to acceptable read times. Even for the most challenging substance, ethanol, bulk reading methods can deliver convincing results with read times of up to 30 seconds. Metal containers are likewise not an issue when suitable on-metal tags are used.

In summary, Kleppinger’s work – including the proof of concept – not only demonstrated the practical viability of RF identification in Merck’s processes, but also revealed that the polarity of the liquids determines the RFID read result. This finding should be taken into account in future evaluations of UHF RFID applications involving liquids. Not every bachelor’s thesis can claim that kind of impact.

Customer | www.merckgroup.com

Holger Anders is a sales specialist at TURCK