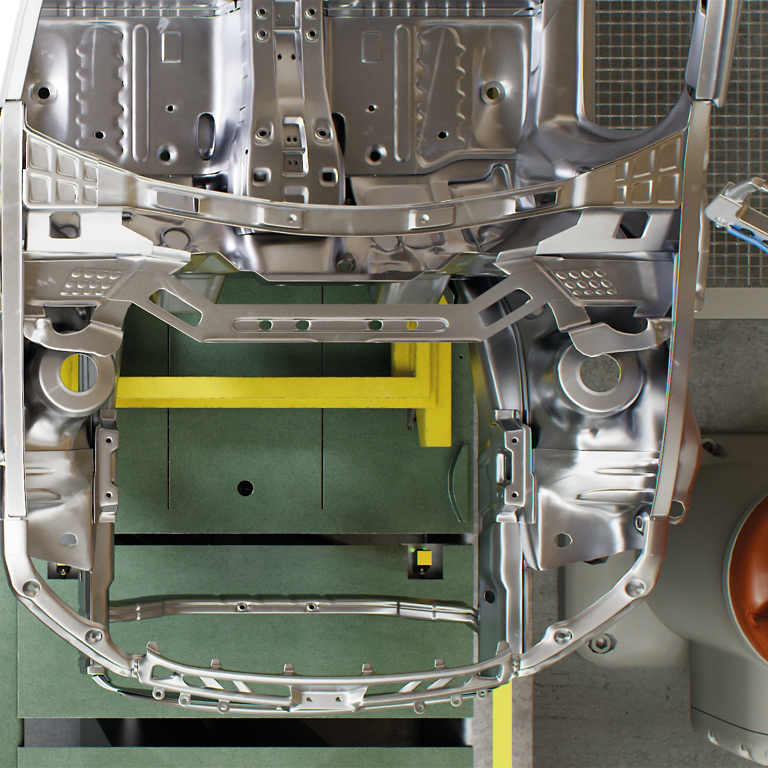

Body identification

TURCK's UHF RFID solution reliably tracks vehicles across all trades with just one tag

benefits

- Cross-trade identification with just one tag

- Maximum detection rate through polarization switching

- Minimal installation effort thanks to Power over Ethernet (PoE) and integrated I/Os

Challenge

A key challenge in digital production and logistics in the automotive industry is to reliably identify all vehicles across all independent trades. Since different identification technologies are often used, networking is severely limited and central data collection is difficult. In addition, important information is still partly recorded in paper form, which reduces the transparency and efficiency of production processes and increases maintenance costs.

Solution

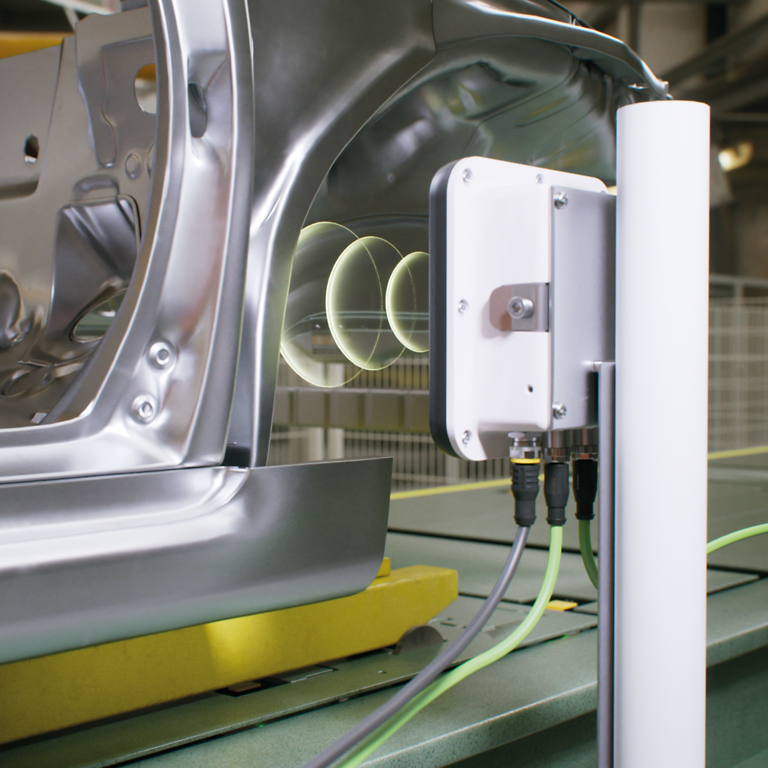

Robust UHF RFID solutions enable the identification of body and body parts across all trades. A high-temperature-resistant RFID tag accompanies each vehicle through the production process and enables continuous identification and tracking from the body shop to delivery. The Q150 RFID UHF reader with polarization switching ensures that tags are reliably detected on several polarization levels, which can increase detection rates, especially in metallic environments such as production lines. The devices can be connected directly to controllers via Ethernet without additional interfaces, which greatly simplifies installation and reduces costs. These measures enable more efficient production control and increased investment security, as the RFID reader can be used flexibly in various network architectures and a separate power supply is not required thanks to Power over Ethernet.

"Our RFID solution provides reliable, end-to-end vehicle identification in multiple production steps."

Hendrik Schnabel | Product Manager RFID Systems | TURCK GmbH