Integrated pharmaceutical tracking with RFID

Together with partners, Turck Korea has implemented continuous serialization and identification of drugs from the production plant to the shipping warehouse

Quick read

Pharmaceutical counterfeiting is a problem for health authorities and competition regulators worldwide. For this reason, the entire production and distribution chain for drugs is to be completely transparent in the future. In Korea, TURCK and other partners introduced this so-called serialization for the pharmaceutical manufacturer Daewon Pharm Co. Ltd. The cloud-based solution tracks the drugs from production to storage in the shipping warehouse. Depending on requirements, identification is carried out using barcodes or data matrix codes, OCR text recognition, or RFID. All identification technologies refer to the same database in the central data cloud.

Around the world, efforts are currently underway to find ways to put a stop to pharmaceutical counterfeiting. After all, in addition to the economic damage (€50 billion per year in Germany alone), there is a serious risk to the health of consumers of counterfeit drugs. The goal is therefore to introduce seamless serialization of pharmaceutical products within the major economic areas. In this context, serialization means identifying all saleable drug packages by serial number throughout the entire production chain. For automated identification of the serial numbers, they are not only printed in plain text but also applied as barcodes, data matrix codes, or RFID codes, depending on the packaging unit.

Serialization in the EU by 2019

Complete serialization is to be introduced within the EU by 2019. All drug packaging must then be identifiable beyond doubt, and this must be possible at every point in the manufacturing and distribution chain. As soon as the medicines end up in the first packaging unit (primary packaging), for example a blister pack, they are assigned to a manufacturer and a batch. This identification must also be possible in larger packaging units, for example at wholesalers or logistics service providers, and ultimately also in pharmacies. Every packaging unit – from blister packs and classic drug packaging (secondary packaging), as sold in pharmacies, to containers consisting of several packages (tertiary packaging), and to entire cartons or even a complete pallet of drugs – must be fully identifiable.

Such a system is relatively complex. Numerous interfaces between the different systems are required, and last but not least all read and write devices must use the same database – in real time.

Pilot project

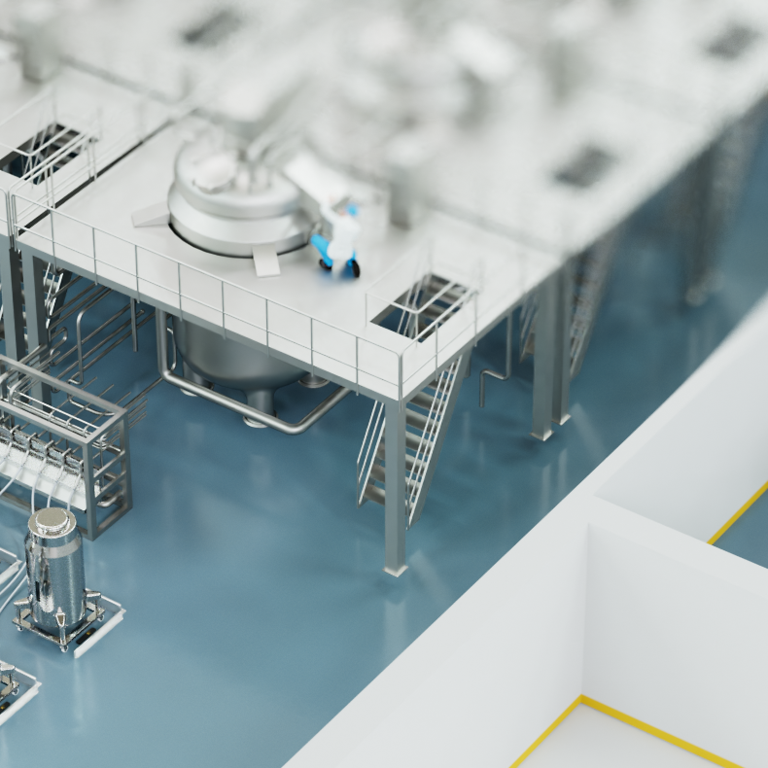

Last year, Turck Korea, together with other partners, launched a solution for the South Korean pharmaceutical manufacturer Daewon Pharm that could also set a precedent in Europe. The company is equipped with state-of-the-art production facilities and produces around 150 different products. Almost 700 employees generate sales of around 137 million euro at Daewon.

The pilot project is an example of automated serialization of pharmaceutical products. This requires more than just the actual identification through barcodes or RFID tags: the data must not only be available in the system at individual points, but also in a network that runs through the entire production and distribution chain in the final stage of development. Currently, serialization takes place until the drugs are stored in Daewon's warehouse. In a final expansion stage, wholesalers and each individual pharmacy can also be integrated into the system and the data cloud. In addition to TURCK, other partners with experience in higher-level IT infrastructure and data connectivity to ERP and MES systems were involved in the pilot project.

The project partners

The biotechnology and pharmaceutical company Hanmi was the main contractual partner in the project and contributed a wealth of knowledge and experience from the implementation of its own RFID solution. Hanmi revolutionized its distribution system with RFID which, among other things, enabled it to expand into the American market. In particular, its subsidiary Hanmi IT had already gained experience with its self-developed supply chain management system "Keidas" on which the Daewon pilot project was based. The software can track all operations in production management – from the start of production to packaging, shipping, goods receipt and the sale of products. All data is not stored locally, but is made available and kept up to date for all members of the supply chain via a data cloud at every point in the production and distribution chain.

This is where other project partners come into play. South Korea Telecom (SKT) provided the data cloud. The company is certified with the IT security standard ISO 27001 and guarantees that the cloud services are set up reliably as well as in a tamper-proof and fail-safe manner. The consulting firm Agathon also supported the project partners in computer system validation.

Turck Korea handled the automation part of the project, developing and building complete machines that can print, fix, check and read the necessary codes and tags on different packaging units. These machines in turn communicate with the Keidas system and map the production and packaging processes there.

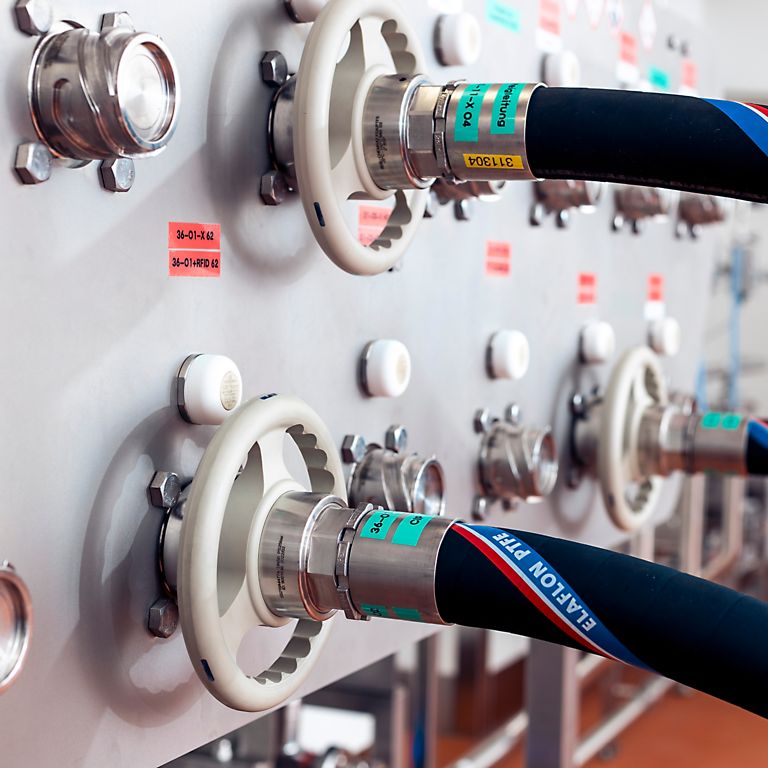

Integrated labeling machine

At the start of production, the Daewon plants use a labeling machine that is integrated into the production process. The drug packets are provided with an RFID tag that is written with the corresponding serial number. In addition, the packets are printed with a 2D code and plain text containing the same information. The RFID tags are checked for correct function directly in the machine and ejected if necessary. The print quality of the data matrix codes and the OCR labeling is also checked. TURCK developed special machines specifically for the project and equipped them with a number of products from its own portfolio: In addition to inductive sensors, cable sets, power supplies, VT250 HMI control systems, and BL20 fieldbus gateways, these also include a number of products from opto-sensing partner Banner Engineering, such as light barriers, emergency stop buttons, cameras, and vision sensors in the system.

Hanmi/TURCK RFID Bulk Reading Machine

Before storage, the individual drug packages must be grouped into larger units, but they must remain individually identifiable to ensure complete traceability. To this end, TURCK has developed and built the RFID Bulk Reading Machine in collaboration with Hanmi. It uses RFID to identify all packages contained in a carton, even if it is sealed. This is a major advantage of RFID over barcode technology: in a bulk reading, RFID can read the entire contents of a carton – up to 500 individual tags.

The packager simply places the carton in the opening of the machine. The reading process starts automatically. A total of ten RFID antennas detect all tags inside the carton. One antenna moves inside the machine to prevent double readings or unread packages. Following identification, the machine initiates the printing of a label with barcode and serial number which is affixed to the outside of the carton for further identification and shipping. TURCK built both a manual version of the machine in which employees place the cartons in the opening, and an assembly line version in which the cartons travel into the machine on a conveyor belt and, after identification, continue on to palletizing. The compact machine is just 1.6 meters high and very mobile..

Identification by forklift

Palletized cartons are then identified on the pallet using RFID tags. The assignment of the data is complete. All readers are connected via Ethernet to computers that always access real-time pharmaceutical data via the central data cloud. This complete identification goes right through to delivery to the pharmacies and the sale of the products to the customer.

The strength of the solution lies in the combination of state-of-the-art RFID technology with equally powerful optical sensor and camera technology. Both technologies – optical identification via bar and data matrix codes or OCR text recognition as well as RFID – have their strengths. The system solution for Daewon Pharma draws its performance and process reliability from the clever combination of both identification methods. The central linking of all data in one place eliminates data synchronization errors and other disadvantages of an asynchronous solution.

Identification

If the costs of RFID and data matrix identification are compared superficially, RFID is about ten times more expensive as long as you only consider the costs for data media and label printing. However, as the pilot project has clearly demonstrated, RFID is the cheaper option when considering all costs (total cost of ownership), including labor costs and equipment. The advantages of RFID lie in the speed and reliability of the processes: identification is not only faster, it is now possible to read up to 500 tags simultaneously without having to unpack the carton – optical processes create a maximum of 200 tags at the same time and also require visual contact. However, since most recipients at the end of the logistics chain, i.e. pharmacies, do not usually have RFID readers, optical identification is also used.

Customers benefit from project experience

TURCK has gained a wealth of experience in the serialization of pharmaceutical products through this pilot project. The expertise gained with fully automated machines and pharmaceutical-specific requirements, as well as in handling projects of this magnitude with multiple partners, is particularly valuable for TURCK and its customers. In Korea alone, ten follow-up projects have already been created, and further discussions are ongoing on comparable projects in Europe, America and Asia.

User | www.daewonpharm.com