Become independent of your customers' control systems!

With TURCK's multiprotocol Ethernet gateways and MTP, your machine modules communicate fully automatically with the most important control systems

Biotech and pharmaceutical industry: short time to market thanks to modular plant engineering and MTP

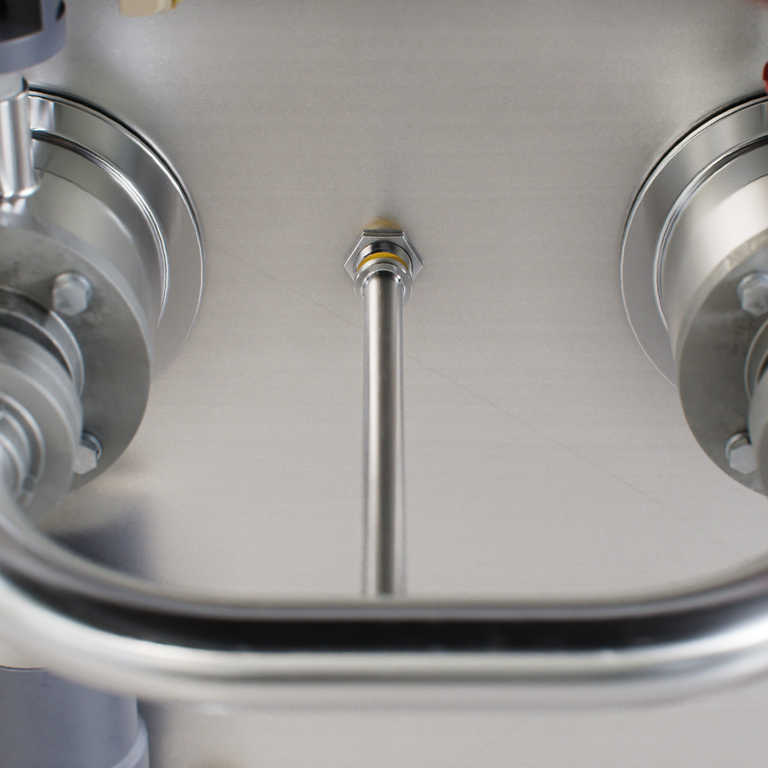

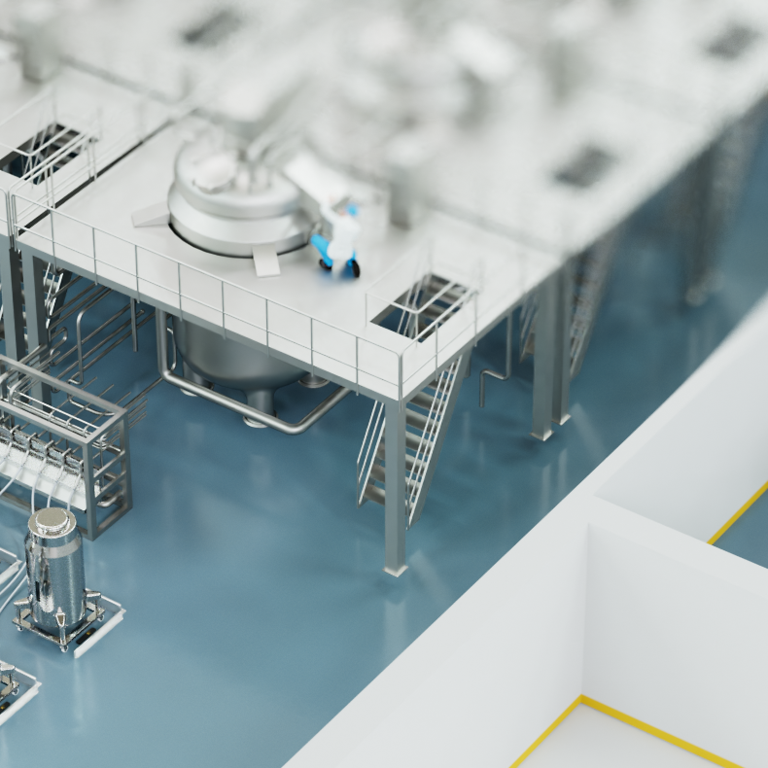

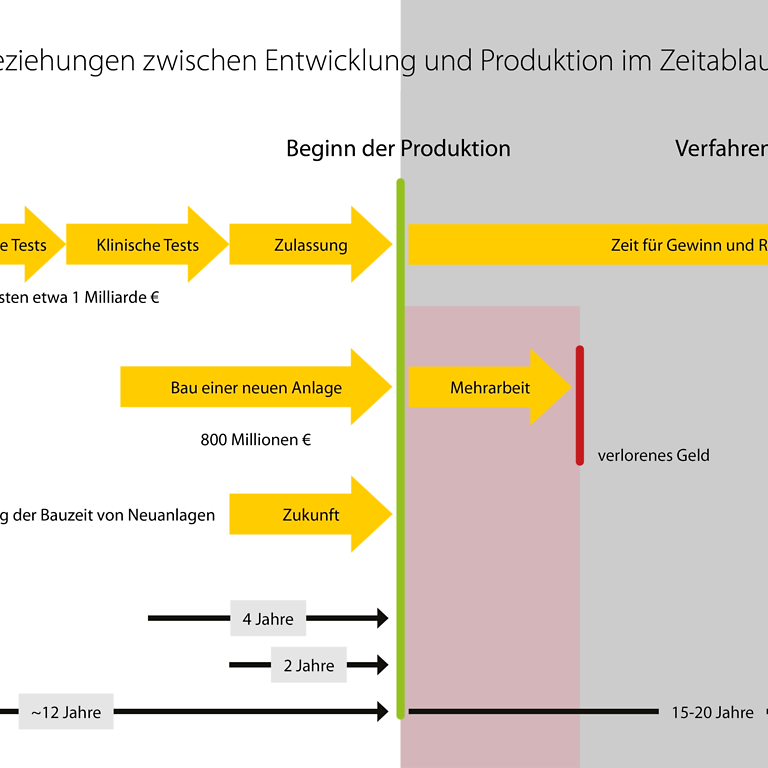

The growing demand for pharmaceuticals poses challenges for the biotechnology and pharmaceutical industries: rapid reaction to market needs and a short time to market (TTM) for new plants are in demand. But how do you speed up the development, production and assembly of your modules? With multiprotocol Ethernet. The integration of PROFINET, EtherNet/IP and Modbus TCP in one technology enables integrators and active ingredient producers to combine modules from different manufacturers with a large number of control systems. The MTP capability of TURCK Edge Controllers increases flexibility and simplifies integration. With TURCK multiprotocol I/O devices, you can modularize plants faster and more easily than ever before, regardless of the customer.

In order to meet the increasing demand for medicines, modular biopharmaceutical systems are increasingly needed, which can be quickly installed anywhere in the world. The use of tried-and-tested modules for biopharmaceutical systems of identical construction saves time and money in plant engineering. Module-based plant engineering in the pharmaceutical industry benefits from the increasing standardization of components. TURCK's multiprotocol I/O solutions are exactly what machine and plant engineering companies need.

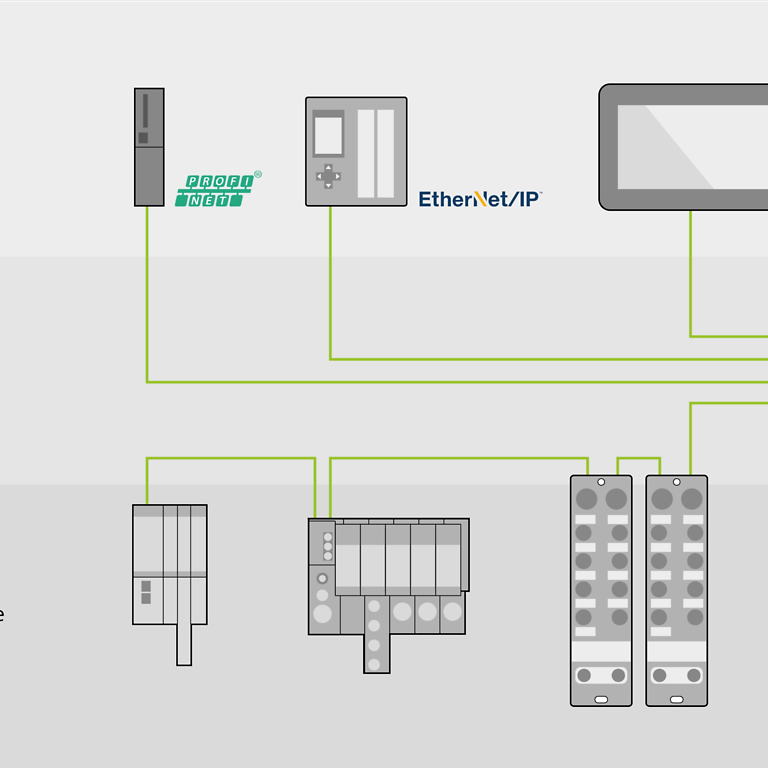

Your customers adhere to their respective plant standards, which is why you need to develop and implement strategies for Skid integration. TURCK's multiprotocol gateway enables your modules to work in PROFINET, EtherNet/IP, and Modbus TCP networks without hardware adjustments. So you only need one gateway model – no matter for which customer. You benefit from reduced development and delivery times as well as reduced storage costs. At the same time, you also enable your customers to significantly shorten their TTM.

Standardized interfaces to the control system

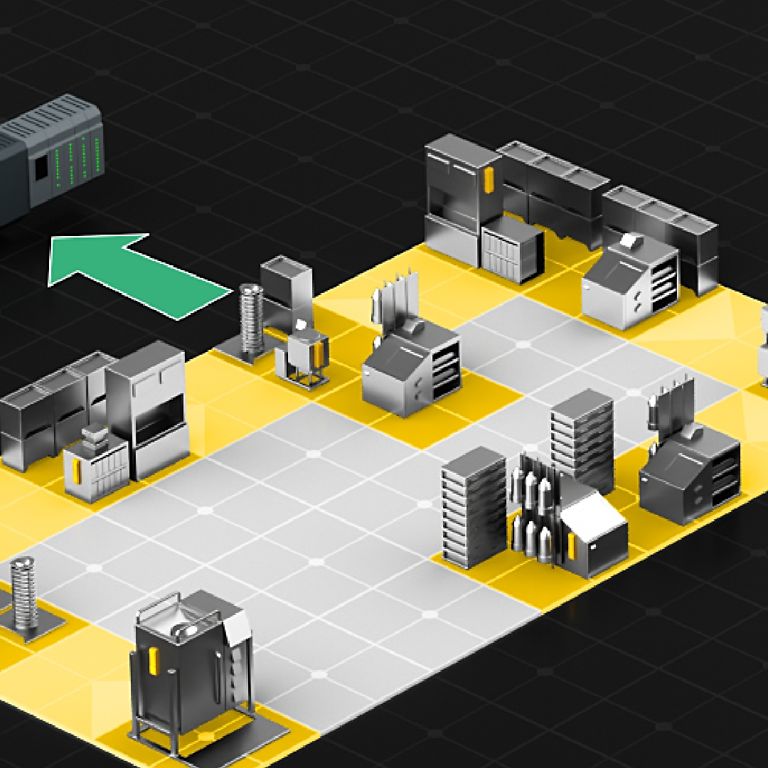

Modularization and standardization

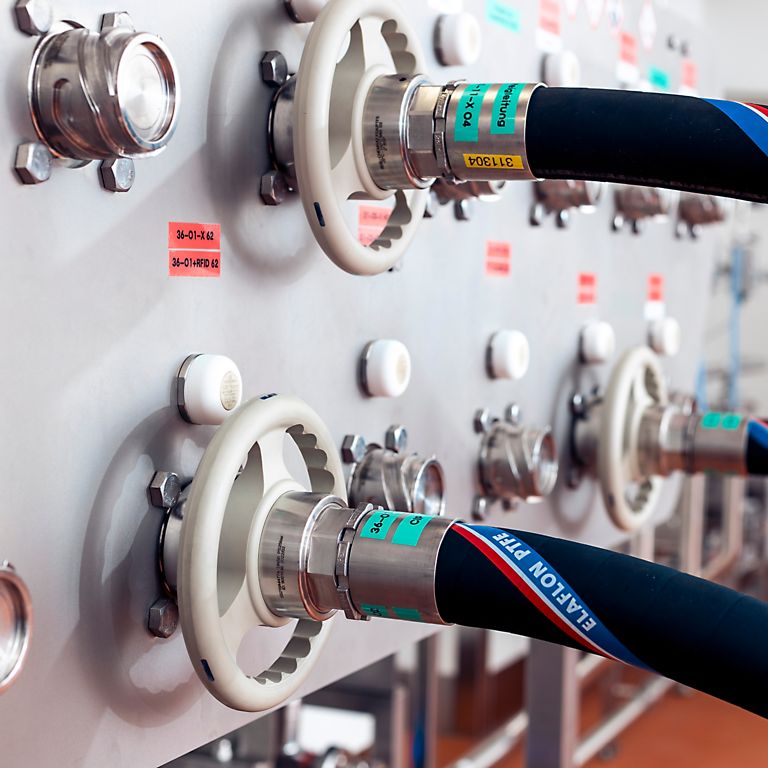

The interfaces are crucial for the high flexibility that comes with modularization. The standardization of these systems ensures that Skids can be replaced and combined. Equipped with TURCK's multiprotocol gateway, your modules are automatically connected to any end-customer control system. This means that you only need one gateway model – no matter for which customer. Thanks to IO-Link or RFID, handling is easier than ever. This will shorten your delivery times and enable you to meet your customers' needs more quickly.

What is MTP?

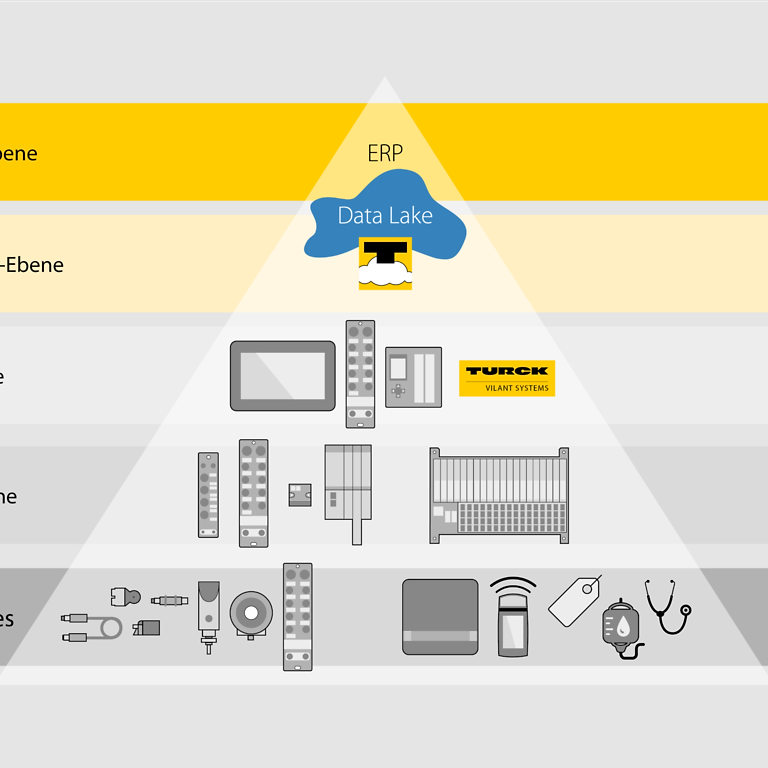

MTP stands for Module Type Package and refers to a standard for the modularization of plants. The modules have decentralized intelligence and provide your services in a standardized manner. MTP files act as a device driver. The higher level, the Process Orchestration Layer (POL), can detect the function of the MTP modules and build their process control accordingly. MTP thus considerably reduces the engineering effort required for modular systems. MTP is the final milestone for the construction of a real plug-and-produce plant.

What is Multiprotocol Ethernet?

TURCK's multi-protocol devices automatically adapt to the Ethernet protocol spoken in the network – and that's the case every time they start up. Multiprotocol devices support the protocols PROFINET, Modbus TCP and EtherNet/IP. TURCK's I/O offering is also available almost consistently with multiprotocol technology, including compact block I/O modules and flexible modular systems – each for use in a control cabinet (IP20) or for use directly in the field (IP67). TURCK offers multi-protocol devices for its BL20 series gateways for control cabinet installation and for the BL67 series for field installation. IP20 and IP67 block I/O modules including the space-saving BL compact series are also available as multi-protocol devices.

Multiprotocol Ethernet gateways and block I/Os

TURCK offers powerful solutions to efficiently record data flow and to prepare existing machines and products for the future. Thanks to key technologies in the fields of fieldbus, RFID, sensor technology or connectivity, such as NAT routing, IO-Link or multiprotocol Ethernet, TURCK's solutions can be used without any problems for the interaction between OT and IT. While RFID and IO-Link contribute to greater flexibility and process reliability, the diagnostic data of a module is passed on to the controller via IO-Link for quality assurance purposes, for example. Thanks to RFID or IO-Link, the modules can also be detected more quickly in the control system via the multiprotocol gateway.