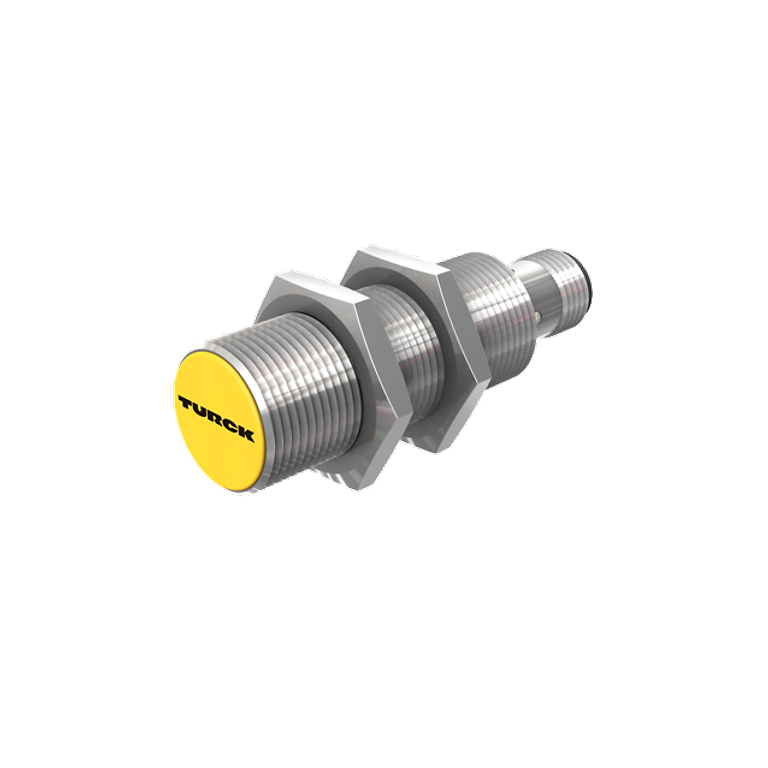

Inductive Sensors

Induktive Wash-Down-Sensoren mit IO-Link vermeiden in der Lebensmittelproduktion Fehler bei der Montage von Rohrbögen und erkennen Dichtungsverschleiß.

Precise information about irregularities reduces plant downtime

Secure functioning thanks to large switching distance with all metals, even when seals are worn

Wash- down design for reliable use in food environments

In food production, pipelines with numerous pipe bends are installed, which require precise assembly and tight connections. Incorrect assembly or worn seals can lead to leaks, production downtime or hygiene problems. Reliable and automated control of the pipe bend position and early detection of wear are therefore crucial to ensure production safety and plant availability.

TURCK's inductive washdown sensors with IO-Link offer reliable detection of the pipe bend position. A switching flag attached to the pipe bend enables the sensor to check the correct position. Thanks to the high switching distance and the option of setting two switching points, the sensor can not only check that the assembly is correct, but also indicate seal wear at an early stage.

Additional diagnostic data, such as switching distance, temperature or operating hours, can be read out via IO-Link. This information enables predictive maintenance and helps to avoid unexpected downtime.

The robust washdown sensors are specially designed for hygienic applications and feature a stainless steel housing with a liquid crystal polymer front cap. They are resistant to aggressive cleaning agents and can withstand temperatures from -40 to +100 °C.

"With our IO-Link-enabled wash down sensors, we ensure reliable assembly control and enable early detection of wear."

Sander Makkinga | Director Product Management Position/Proximity Sensors | TURCK GmbH