Compact Ex isolation in paint and coatings production

Wilhelm Niemann Maschinenfabrik ensures reliable operation of its machines with safe and efficient explosion protection solutions from TURCK, consisting of precise sensors and fast, compact interface devices.

Quick read

Wilhelm Niemann Maschinenfabrik manufactures mixers and mills for the paint, coatings and chemical industries. Customers use them almost exclusively in hazardous areas. In the control cabinet, the manufacturer based in Melle installs space-saving isolating switching amplifiers and temperature measurement amplifiers from TURCK's IMX12 interface series. These send signals from the operator pushbutton to the field and transmit intrinsically safe digital and analog input signals. For vertical positioning of toothed discs, Niemann has also relied on IM36 potentiometer amplifiers for several years. TURCK inductive NAMUR proximity sensors have been in use even longer and have impressed Niemann with their long switching distances.

"What's written on the label has to be inside"—this principle carries special weight at Wilhelm Niemann Maschinenfabrik. From custom screws to pneumatic cylinders, the Lower Saxony–based company manufactures a wide range of components for its industrial and laboratory equipment in-house. Customers can be found on every continent, most of them manufacturers of paints, coatings, adhesives or silicones. "We follow the premise: made in Germany, made by Niemann," says Hendrik Werges, Workshop and Project Manager for Electrical Engineering.

To outsiders, the diversity of Niemann's machine configurations is not immediately apparent, especially since only three basic machine types are ultimately produced in Melle-Neuenkirchen. The dissolver is suitable for mixing processes as well as for dispersing: a rotating toothed disc breaks up solid materials in a liquid, grinds them and mixes them. The result could be wall paint. Even finer grinding of pre-dispersed material is achieved by the basket mill. Here, the suction generated by a pump disc draws the product through a basket filled with ceramic beads—a principle relied upon, for example, by manufacturers of automotive coatings.

Customized machines

As product viscosity increases, so do equipment requirements. "There are highly viscous products where the dissolver disc would only bore a hole into the material," explains process engineer Michael Diddens. To ensure that the contents of the vessel are moved at the same time, Niemann's third machine series, the 'Butterfly' circular dissolver is also equipped with a centrally positioned butterfly tool with scrapers mounted on the outside. Rotating slowly, this tool ensures homogeneous mixing of the material, for example in the production of sealants, and feeds it into the dispersing zone of the eccentrically mounted dissolver toothed disc.

Depending on product requirements, customers select one of these basic machine types, but in practice place far more extensive demands on the machine design. The engineering office of the family-owned company must prepare its project drawings in accordance with the on-site conditions at the customer's facility, whether a 5000-liter vessel is required despite limited ceiling height, or the cooling circuit of the mixing vessel needs to be supplemented with a heating function to manufacture a specific product. In addition, Niemann supplies its dissolvers either in a standard version or as a mounted version for installation on steel platforms or intermediate floors.

"TURCK's sensors in this design have the advantage that their switching distance is usually one to two millimeters greater than that of competitors"

Hendrik Werges | Werkstatt- und Projektleiter Elektrotechnik | Wilhelm Niemann Maschinenfabrik

Safety in the tightest of spaces

Nearly all of the machines have one thing in common: they are used in potentially explosive atmospheres. This has to be addressed in the control cabinet outside Zone 1. Niemann generally uses one of two approaches, depending on whether a complex control system is required. Touch panels on the machines require PLC support anyway and in about 90 percent of cases, this also applies to operation of the 'Butterfly' dissolver. In that setup, safely encapsulated Profinet or Profibus cables can run from the PLC in the control cabinet to the operator interface.

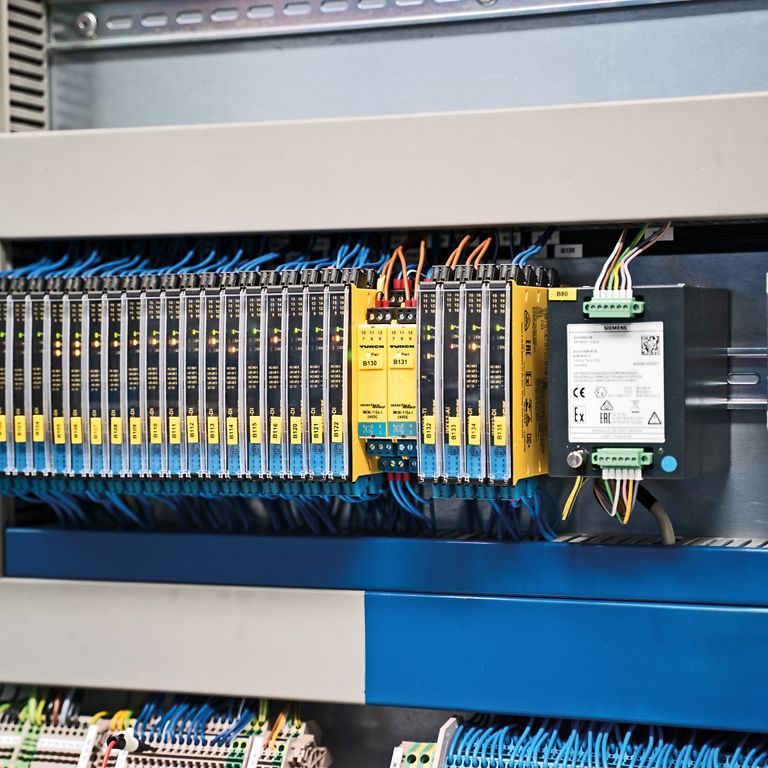

However, not every company has PLC programming expertise and in some cases a fieldbus is simply not needed. In those situations, Niemann uses a second approach based on hardwiring rather than PLC technology. Pushbutton signals are sent to the field via TURCK IMX12 isolating switching amplifiers. Devices from the IMX12 interface series are also used when operators need to bring specific digital or analog values out of the hazardous area. This allows proximity sensor signals or temperature values to be transmitted in an intrinsically safe manner to the control cabinet.

A slim design and a power distribution rail were key requirements for purchasing the new isolating switching amplifiers. TURCK's IMX12 devices met both requirements with a width of just 12.5 millimeters and power delivery via a power bridge. This means the individual enclosures are powered via the DIN rail in the control cabinet, eliminating time-consuming jumper wiring for panel builders. In addition, the IMX12 eliminates the need for a separate power infeed module since a single connector is sufficient for the linked row.

Three environments, three sensors

Niemann had been using TURCK sensor technology long before the interface devices. As a result, the interface modules now also convert some of the signals supplied by field sensors. "TURCK's sensors in this design have the advantage that their switching distance is usually one to two millimeters greater than that of competitors," says Hendrik Werges. And these differences in range can make many things easier.

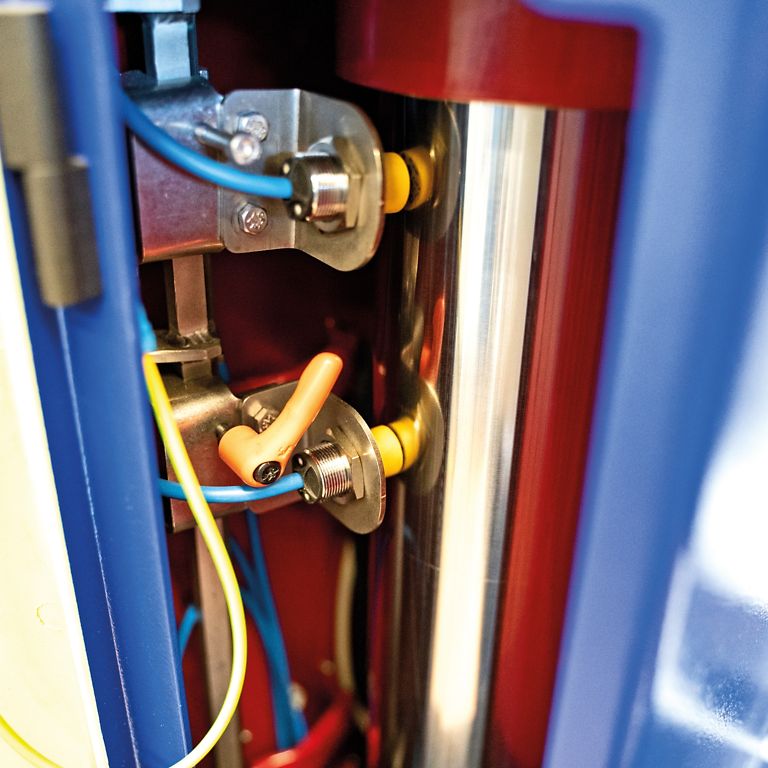

For example, the Lower Saxony-based company installs inductive M18 proximity sensors in the columns of its machines to monitor heights. To raise a machine, a hydraulic ram moves within the column. However, it must not exceed certain limits so that the toothed disc runs only inside the vessel or the lid remains in place. To limit the stroke and as a safety-relevant circuit, sensors are installed at suitable points to detect the central ram. Installation is complicated by a reinforcing ring about four millimeters thick at the lower end of the ram, which the sensor must not obstruct. Despite the distance, the sensor must detect the cylinder and the ring. This is where the advantage of the TURCK NI10-G18 proximity sensors with NAMUR output becomes apparent. They are suitable for Ex Zones 0 and 20 and are installed by Niemann in numerous products.

If you are looking for one of the smallest TURCK components in a Niemann machine, you have to look very closely. With a housing length of 31 millimeters and a height of six millimeters, the BIM-UNT-AY1X magnetic field sensor is concealed in the lid hinge of a vessel fill opening. There it detects whether the closure is open or closed. The miniature sensor has a clearly visible 360-degree LED and is securely clamped into the groove using a special screw.

A custom inductive sensor must withstand conditions in the drive unit. In this particularly demanding environment, it monitors a switching flag. The reason: mounted dissolvers with volumes of up to 15,000 liters require a scraper, but during filling it should not be positioned under the ball valves in order to avoid buildup. The designers therefore defined a park position for the vessel scraper and installed a detection plate at the top of the chain drive that the sensor detects.

IM36 passes the speed test

The position of the toothed disc within the vessel is determined by a draw-wire sensor. Via the contact of the measuring wire, it outputs resistance values that must be converted into an analog signal. For this purpose, a potentiometer amplifier converts the signal into 4–20 mA as quickly as possible in an intrinsically safe manner, so that connected systems can control the height smoothly without jerking.

As recently as five years ago, this process occasionally caused problems, as Werges reports from practical experience: "In the recipe, customers specify certain heights at which the toothed disc is to operate. If the conversion takes too long, the machine misses these points by a few centimeters and then continuously hunts back and forth." The solution required a signal converter with a cycle time of less than 700 milliseconds. That was how Niemann first came to use TURCK interface technology, specifically the IM36 amplifier, which converts within 30 milliseconds and enables stable positioning of the toothed disc within the hysteresis band. As a specialist for fast analog conversion, the IM36 has been installed in Niemann machine control cabinets for some time

and has recently gained familiar neighbors in the form of the slim IMX12 amplifiers. The Lower Saxony-based machine builder is currently testing another solution using TURCK sensor technology, in which initiators are intended to replace the previous solution for limiting the speed of older drives. "But that falls under spare parts business," explains Hendrik Werges. In current machines, the speed is controlled either by the frequency inverter or by the operator via a potentiometer in the control panel. Such tactile adjustment continues to be appreciated by customers.

Customer | www.niemann.de

Author | Joachim Ricker is a sales specialist at TURCK