Ethernet Gateways for Safe Process Data in Zone 2

With the first zone 2 Ethernet gateway for its high-availability excom I/O system, TURCK is now introducing Ethernet communication to explosion-protected areas

Quick read

With the first Ethernet gateway for the excom I/O system, TURCK is opening up the world of the process industry to digitalization and Industry 4.0. A parallel data channel is used to send all process data to IT systems for analysis and evaluation at, for the first time, a sufficient speed — the quick and easy way to efficient condition monitoring and predictive maintenance. Controllers and control systems remain completely unaffected and protected from access. Because it is so compact, the system is not only suitable for installation in the field, but also in MSR rooms.

The longer-lasting innovation cycles in process automation require a focus on the future, especially when it comes to new plants – the future of the plant and that of the automation technology. You don’t have to be a prophet to realize that a keener diagnostic focus on processes and instrumentation will become even more important in the future.

Plant planners face the question of how to design automation systems on every level to allow effective use of more detailed data as well. And even if its use is not required today, production plants that often operate for decades need to integrate a channel for data-driven optimization today. Anyone who already has specific projects on the books must open up its automation system for monitoring and optimization (M+O), as NAMUR refers to it.

The fieldbus bottleneck

When classic fieldbus solutions are used, whether with Profibus-DP, Profibus-PA or Foundation Fieldbus, the bus physics form a bottleneck for more detailed diagnoses that do not originate from the sensor itself, and instead are made in higher-level systems outside the control systems. This means that many of the metadata that HART, Profibus PA or Foundation Fieldbus field devices are already able to supply and transmit today are only used sporadically in the event of device replacement or calibration due to the limited bandwidth of the fieldbuses (31.25 kbit/s with Profibus PA and Foundation fieldbus, 1.5 Mbit/s with Profibus-DP-IS). However, opportunities for data-driven process optimization or early identification of wear and contamination, known as predictive maintenance, are not being exploited.

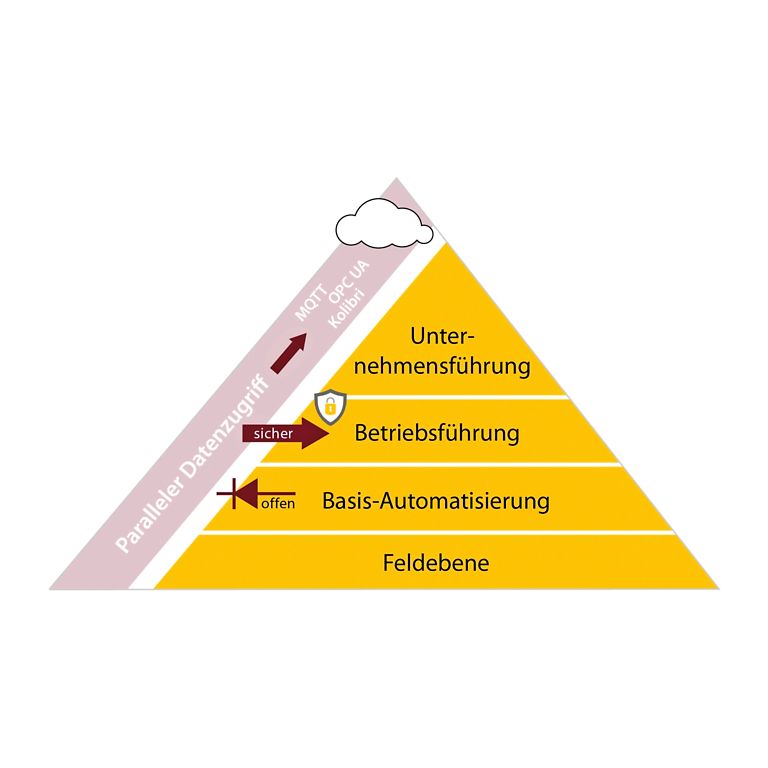

Parallel data access for monitoring and optimization

NAMUR identified this need and responded to it with its NAMUR Open Architecture (NOA) concept: NOA allows an additional data channel to be set up parallel to the automation pyramid. The leaves the lines between field devices, I/O and control system levels unchanged. The data is moved to the parallel channel below control system level, where it can be analyzed separately from the classic automation technology. The parallel channel can thereby benefit more from the shorter innovation cycles of the IT world than would ever be ventured in “operational technology” for plant automation and control. What’s more, this architecture prevents external access to control systems.

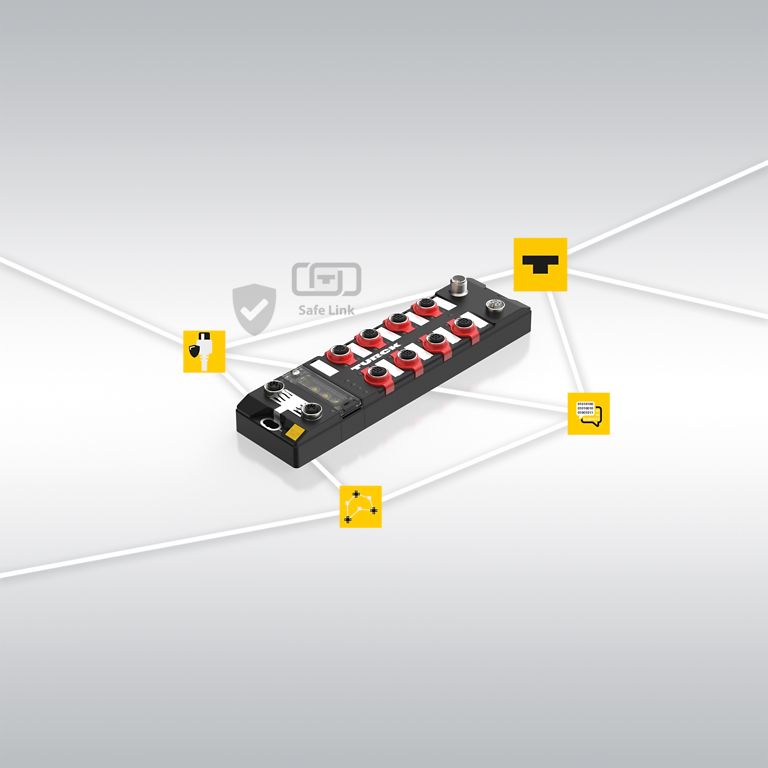

Ethernet for excom opens parallel access to process data

With its first zone 2 Ethernet gateway, TURCK is opening up its high-availability excom I/O system for parallel data access in explosion-protected areas. The automation specialist first presented an Ethernet gateway for excom in the safe zone in the fall of 2019. The gateway now being introduced is designed for use in zone 2. A replacement of the gateway, for example, has no impact on the modular excom system with different electronic modules for inputs and outputs, as well as other signal types. As before, suitable intrinsically safe field devices can be connected for use up to zone 0. Modules and module racks in existing installations can still be used with the new Ethernet gateways.

In greenfield projects, the automation system of a plant can already be designed for parallel data access with excom today. When it comes to brownfield projects, converting to Ethernet would only be viable for most operators if the control system had to be updated anyway. In this case, excom allows the plant to be designed for parallel data access using Ethernet in a range of scenarios, while retaining the existing field devices. excom can be installed both centrally in the MSR room and as a distributed installation in zone 2.

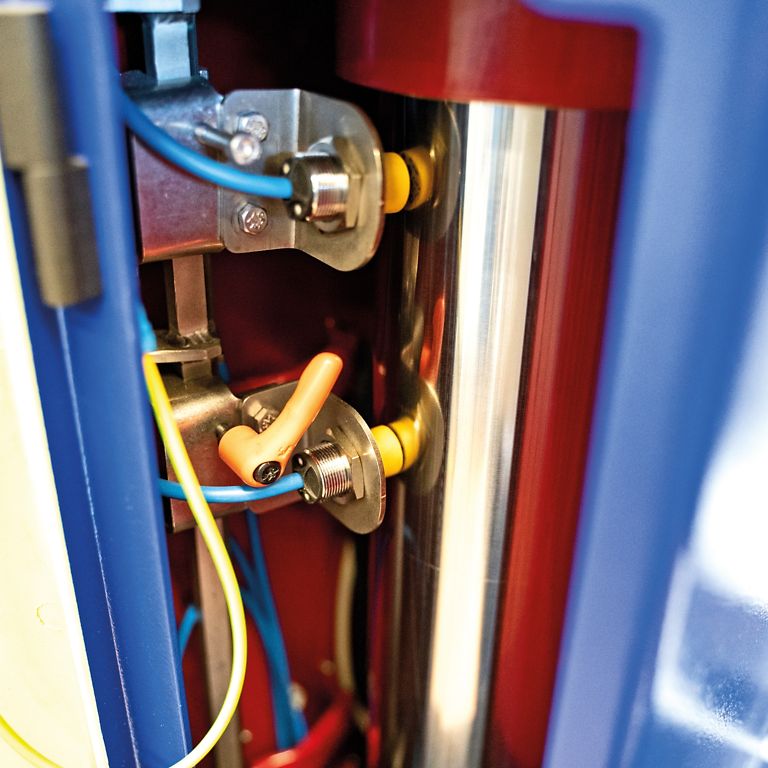

Space-saving installation in an MSR room

Since excom integrates explosion protection, there is no interface technology or corresponding control cabinets. The system replaces the I/O modules in the control system and receives the signals directly from the field devices. This makes these installations much more compact than solutions that use conventional interface technology. TURCK’s excom system generally also requires less space in comparison to other I/O systems with integrated explosion protection. This can have a decisive benefit in the event of retrofit projects in particular, but also in modular process plants.

One and the same system for all three zones

The unique selling point of excom is its comprehensive system concept: the system is suitable for use in the safe area, as well as in zones 1 and 2. Although the gateways and modules for the safe area are slightly different from the intrinsically safe modules, the system is identical from the perspective of the control system. The user can therefore use one DTM and the same operating philosophy across all zones and system components, which in turn minimizes the training required and allows flexible assignment of operating personnel.

System approval makes a new approval unnecessary for extensions

Another characteristic originates in the consistent system concept: excom has approval as a complete system. The approval therefore not only covers electronic modules and module racks, but also installation in the housing together with any customer-specific components. This approval allows for any configuration combination with I/O modules and gateways of the system. This not only enables replacement of a fieldbus with an Ethernet gateway, but also a complete reconfiguration with excom components – without requiring another acceptance process by the approval board. The plant operator completes the required re-evaluation of the temperature values in the housing itself.

Multiprotocol Ethernet

TURCK’s multiprotocol standard has been a familiar feature in factory automation for many years now. Multiprotocol devices can be operated in the three Ethernet protocols PROFINET, EtherNet/IP and Modbus TCP, with or without user intervention. The excom Ethernet gateways benefit from this development, because the system is ready for immediate use with all control systems that support EtherNet/IP, Profinet or Modbus TCP: these include Siemens, Honeywell, Rockwell, Yokogawa, Emerson or Supcon.

Maximum availability

In addition to Profinet S2 redundancy (two controls), excom also supports ring topologies. Even for Ethernet protocols that do not have a redundancy specification of their own, excom uses it to establish system redundancy in the same way as the S2 standard, gateway redundancy or combinations of the two. This means that maximum availability can be achieved even with Ethernet protocols that do not actually feature native support for this function.

Cloud connection

In addition to the transmission of time-critical user data to the control system, excom also features a second channel that establishes the parallel data stream to any other system. There is also the option of analyzing data on an Edge device first, and then sending the results to the cloud.

Autor | Jorge Garcia ist Produktmanager Feldbustechnik Prozessautomation bei TURCK