Anyone who has followed the technology and IT press closely may have read the obituaries for the smartphone a few years ago. Its time was supposedly up—most recently, prominent Silicon Valley CEOs predicted as much. Frequently cited successors include smart glasses, smartwatches and digital assistants such as Amazon's Echo with the Alexa assistant, as well as similar devices. When technologies transition, they create room for innovation. In this respect, consumer and B2B business are alike: when existing device types are replaced or become obsolete, their function—what they provided for a plant or machine—has to be taken over by another device.

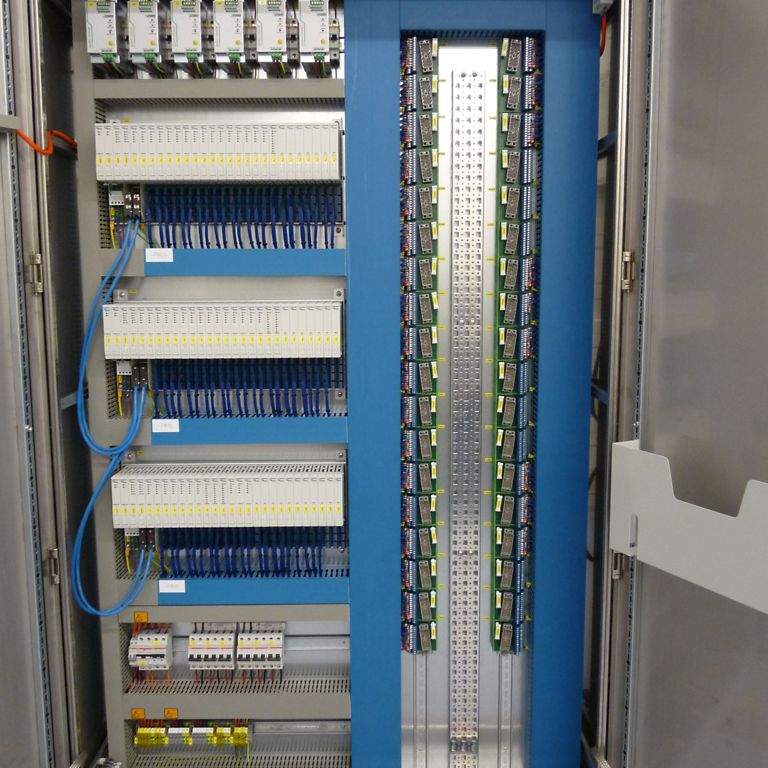

Seen in this light, brownfield projects in the chemical industry can be viewed the same way. At petrochemical group Chevron Phillips Chemicals International NV (CPChem), TURCK's excom now replaces the previous I/O system and the formerly separate Ex isolation in a single enclosure. This frees up space in the I&C room, creating room for plant expansions and innovative technologies. The Beringen site has been part of CPChem since late 2011 and was founded in 1991 by Finnish refining company Neste. Polyalphaolefins (PAOs) are produced in Beringen and used in synthetic oils and lubricants, and customers for these oils include the automotive industry and other industrial sectors.

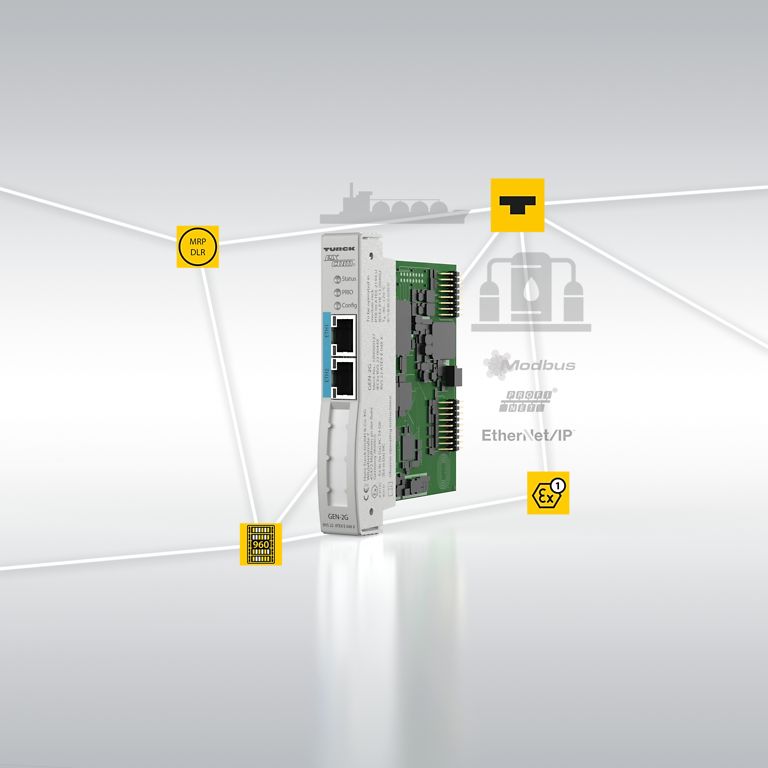

In 2013, the Finnish manufacturer discontinued the I/O system for the Honeywell control system used in Beringen. CPChem's responsible technicians therefore began looking for alternatives. They needed a system that could be connected to the Honeywell control system via Profibus DP and that would provide Ex isolation of the signals—i.e., supply both intrinsically safe and non-intrinsically safe devices. In addition, the system needed to be flexible and support modern diagnostic capabilities and open standards. The new I/O layer also needed to occupy as little space as possible and not affect plant availability.

CPChem approached control system manufacturer Honeywell, which proposed TURCK's excom I/O system as a replacement solution. Honeywell and TURCK have already demonstrated their strong collaboration worldwide on numerous projects—both in terms of the teams involved and the systems deployed. In addition, CPChem researched other potentially suitable systems independently.