Over the past five years, many companies have had to check their own crisis resilience more frequently than they would have liked. Starting with coronavirus and the resulting damage to supply chains, through the gas shortage and the resulting sharp increase in energy costs in 2022, right through to the emerging customs conflicts. But how can crisis resilience be built up if no one knows what the nature of the next crisis will be? If you can derive advice from the multiple crises, it is that you must never rely on the status quo and the current solution.

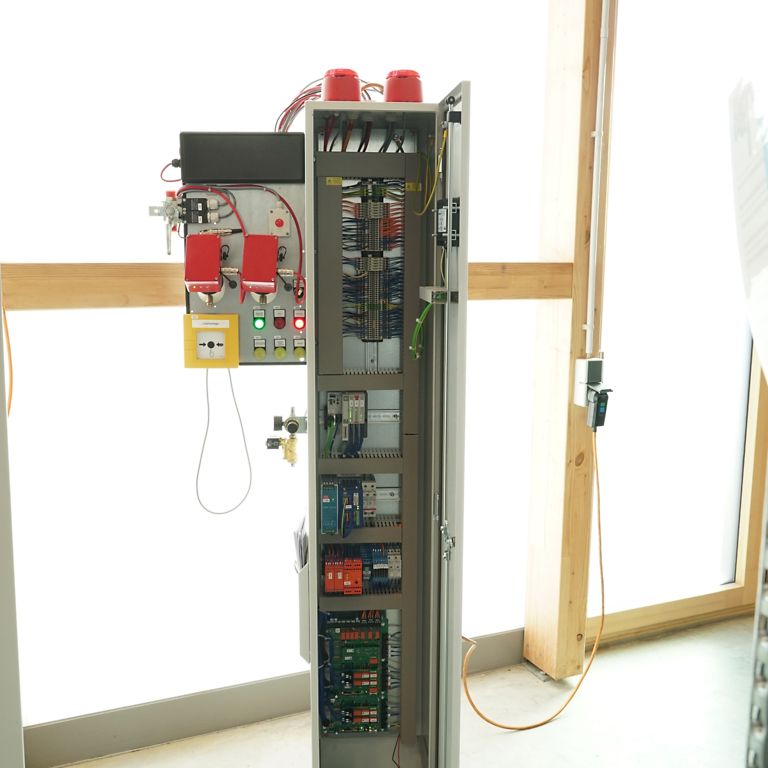

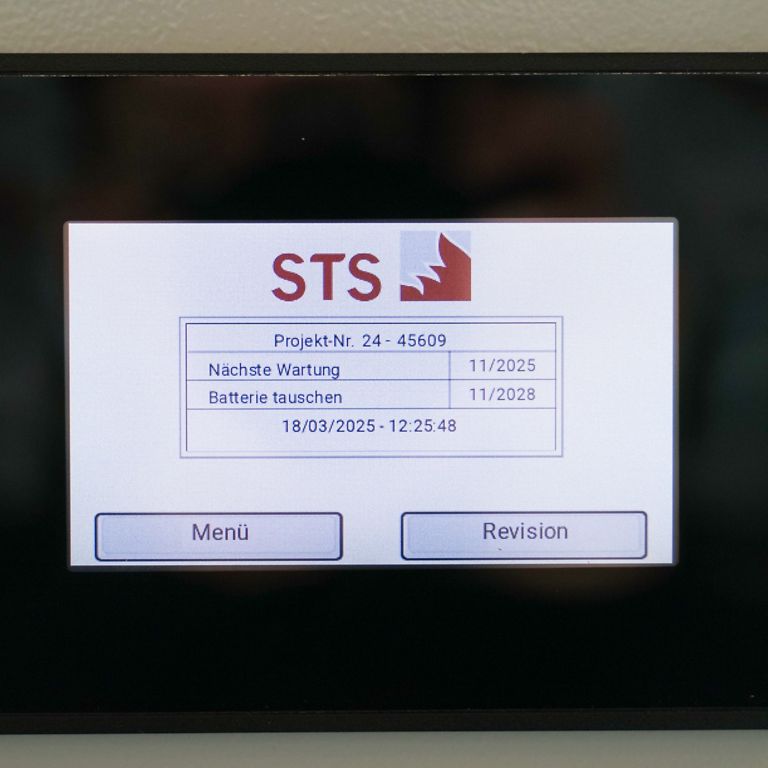

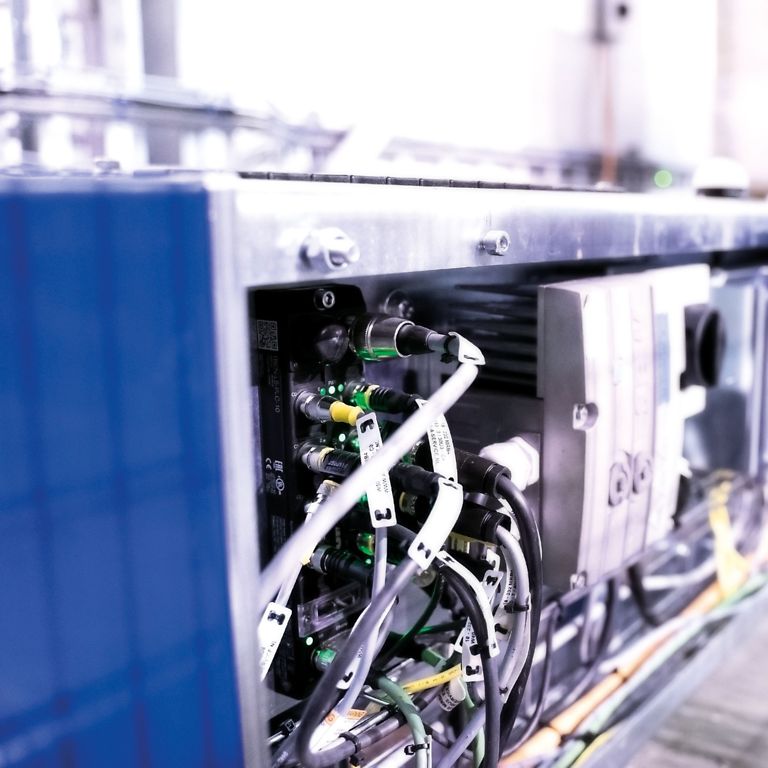

STS Brandschutzsysteme GmbH, based in Friolzheim, Germany, also had to recognize this when its supplier of HMI controllers virtually discontinued its deliveries for months. STS Brandschutzsysteme specializes in the planning, delivery, installation and maintenance of customized fire protection systems for industrial machinery and equipment. The solutions offered include fire-fighting systems for filter and suction systems, machines, and wet paint and powder coating systems.

Standards separate machine and building fire protection

As in many other industrial and economic sectors, standards and regulations structure the business. For example, the market for building fire protection systems may logically be in direct proximity to the fire protection systems of STS. However, different standards apply in the area of building fire protection than in the area of machine and plant construction – and STS therefore does not offer any systems for building fire protection. STS Brandschutzsysteme focuses on its market and its customers. With many of them, the company has a long-standing partnership and a relationship of trust that has grown accordingly on many levels. They understand and rely on each other – especially in crises.