RFID-based self-service concept

To implement this idea, ProMart was looking for a system that could identify all of the goods that had been utilized on site as well as several hundred users working as employees of subcontractors, for example on a shipyard site. This would ensure that the goods used could be billed without the need for staff. The RFID technology is particularly well-suited to automated warehouse management. With more than ten years of experience designing self-service stores, Turck Vilant Systems (TVS) was the ideal partner for this project. ProMart decided to make a few adjustments to the standard TVS self-service store package.

Within the TURCK Group, Turck Vilant Systems is the specialist in turnkey RFID solutions, particularly in production logistics and goods tracking. The company advised ProMart on all issues relating to the installation, operation and optimization of the EasyMart Store and provided both the hardware and the software and IT infrastructure, including server landscape, for the permanent operation of the systems.

The Ready-to-Business approach employed by TVS means that the self-service stores can be optimized to ProMart requirements with just a few adjustments to the standard software, significantly accelerating the commissioning process. The software is designed to cover the most key requirements of automated warehouse management. This includes administration for numerous users as well as various user roles with different rights, such as buyer or borrower, warehouse clerk, etc.

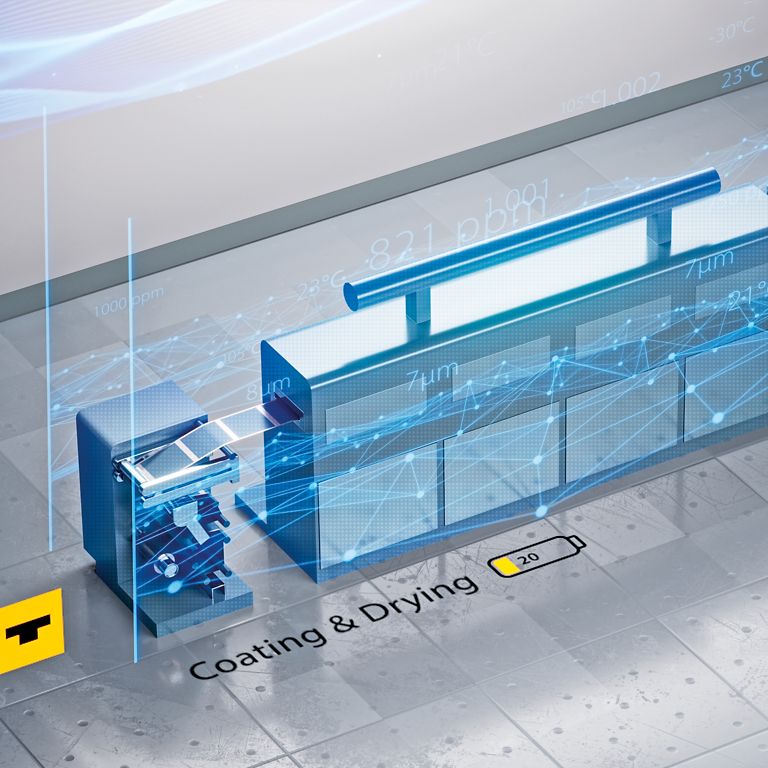

RFID real-time system replaces time-consuming inventory work

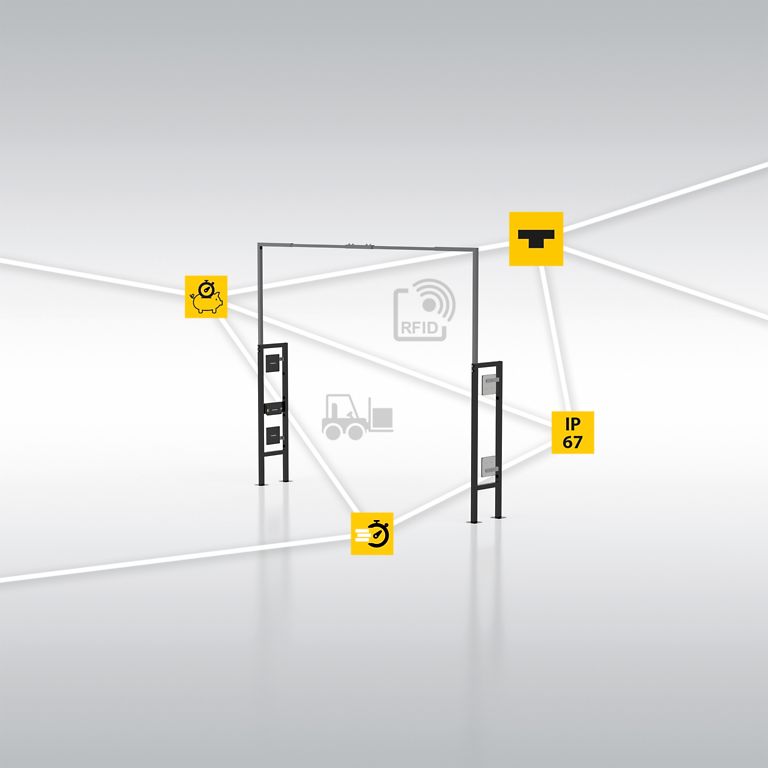

The key to ensuring a completely transparent flow of goods within this application is for the RFID readers to log relevant movements of goods and to transmit their data to the ProMart control center in real time for further processing. With this real-time inventory, the store's stock levels are always known, without the need for employees to pick, count and list each item in stock. Based on the scanning processes, the system automatically creates filling lists and bills. Furthermore, there is no need for costly downtime or equally costly overtime outside of working hours in order to conduct a full inventory.

The first step is for the ProMart customers, who in the application presented here are subcontractors on a shipyard site, to be given the opportunity to configure the EasyMart Store and to arrange the optimal product range. The employees of the subcontractors are then created as users in the system. The TURCK Vilant RFID platform offers the option of managing user access rights and roles for each individual EasyMart Store. For example, user roles can be created that allow users to purchase items and also to borrow them. Prebooking can also be displayed via the system.