RFID system identifies solar cell carriers

Chinese solar cell manufacturer uses TURCK's RFID system to increase the quality and efficiency of its production

Quick read

A Chinese system integrator automates the quality assurance and traceability of its customer's solar cell production using RFID technology. It chose TURCK's BL ident® RFID system, which can be seamlessly integrated into existing plants. This solution enables real-time control and monitoring of the individual production steps, provides reliable data for production management and enables comprehensive, timely and exact production monitoring on site.

A Chinese system integrator was therefore commissioned by a manufacturer to collect this data for its solar cell production in order to derive well-founded production decisions. An automated solution was required to guarantee smooth production and quality control. Consequently, the customer relies on RFID to implement data acquisition and processing as efficiently as possible in the entire production process. Non-contact RFID technology enables products to be tracked and anomalies identified in real time, enabling informed, data-based decisions to be made in a timely manner.

Production tracking by recording wafer carriers

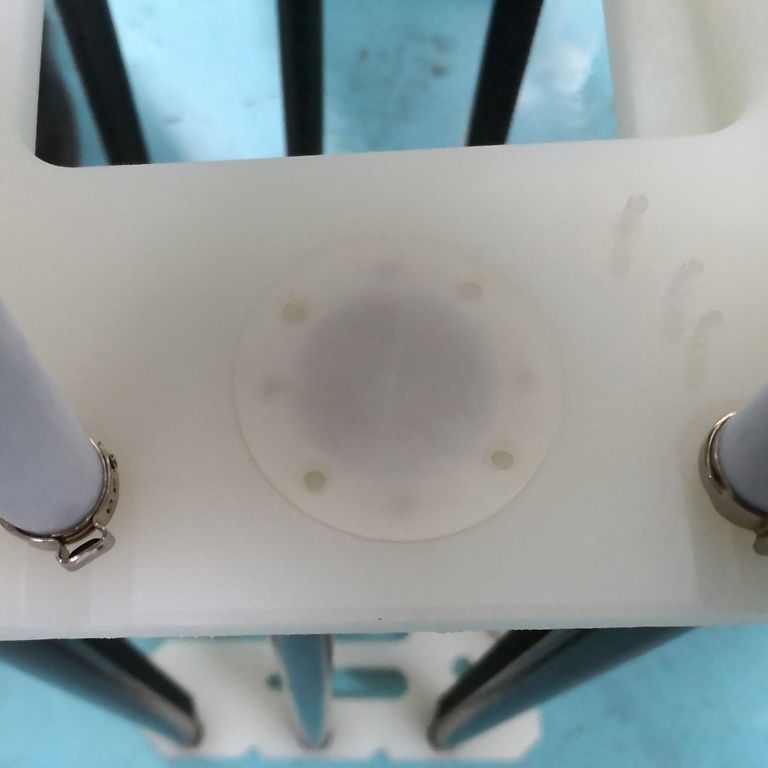

Quality assurance and control play a crucial role in the production of solar cells. The complex manufacturing process requires precise assignment of production batches down to the individual silicon wafers. The solar cell wafers are transported and stored in special wafer cartridges between the production steps. These wafer carriers are designed to protect the solar wafers from external influences such as dust, moisture, and mechanical stress. By installing RFID tags, each wafer carrier receives a unique identification code to which a production order is assigned.

Read/write devices are installed at the stations of each process step, which capture the information from the tags as soon as they enter their reading range. Based on the collected process data, an RFID data acquisition system was set up that automatically feeds the information into the system and interacts with it in real time. This allows real-time wafer information to be retrieved and analyzed on each production line, enabling accurate on-site production monitoring and real-time decision-making.

RFID solution impresses integrator

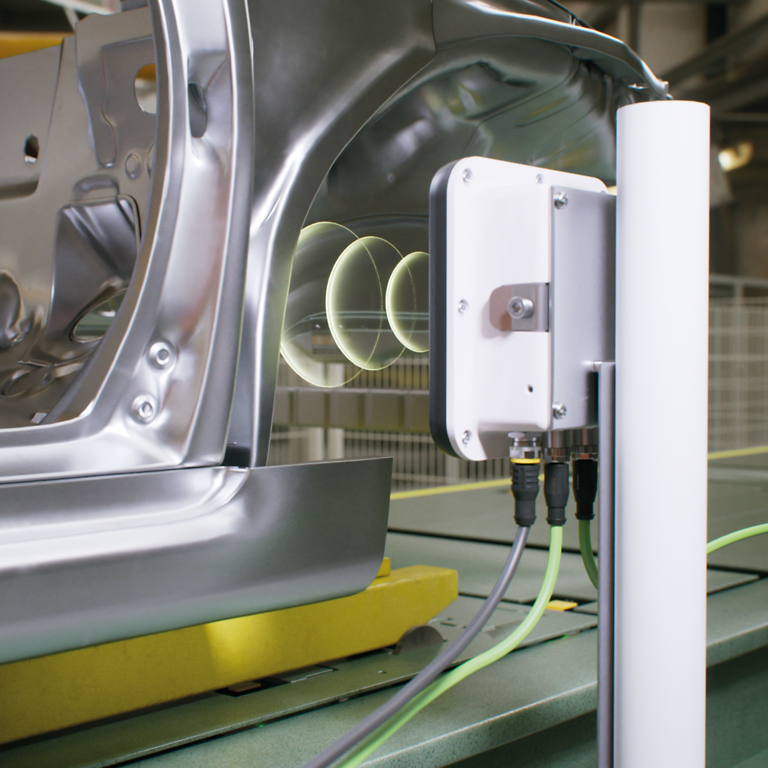

Thanks to its modular and varied structure, TURCK's BL ident® RFID solution can be easily adapted to any application and integrated into existing plants. Standardized software modules are available for easy system integration and commissioning. The system could be easily integrated into the complex process of solar cell production.

TURCK's TBEN RFID modules support three Ethernet protocols with Profinet, EtherNet/IP and Modbus TCP, which in turn are compatible with the controllers of many manufacturers. The user is thus able to reduce the number of different variants in the warehouse and also to reduce the products to be held in stock for each project, which saves considerable costs. During maintenance and repair, the system integrator appreciates the possibility of replacing the components of the RFID system during ongoing operation and thus minimizing downtimes for its customers.

The tags, which are robust enough for this application in solar cell production, also impressed in this specific project. Tags in protection class IP68 can be stored for up to 100 hours at temperatures of up to 140 degrees. Thanks to the 16-kilobyte data buffer of the TBEN RFID interface, the wafer carriers no longer have to wait in front of the read/write devices until all read/write processes have been completed. This allows the manufacturer to achieve a higher production speed without reducing the quality. The TBEN module also offers an integrated switch that enables a line or ring topology and thus simplifies network cabling.

All of these features impressed the customer and enable it to achieve decisive efficiency gains in its production. "By using TURCK's RFID solution, the company is now able to track all production processes continuously and ensure high process quality. The RFID system not only improves the flow of information, but also provides a reliable basis for well-founded decisions on future optimization," the system integrator summarizes.

Autor | Lin Qiang | Marketing & Product Management Department | Turck (Tianjin) Sensors Co.