RFID access control for autonomous inspection robots

At BASF's Antwerp site, a four-legged inspection robot helps ensure the safety of the water treatment plant and TURCK's RFID solution provides reliable access to its charging station

Quick read

To make inspection processes safer and more efficient, BASF's Antwerp site uses an autonomous inspection robot that performs key monitoring tasks independently. A Turck Multiprox RFID solution controls the robot dog's access to its 'charging hut' and also protects the area from unauthorized entry using TURCK's UHF RFID reader and the compact TBEN-S-RFID interface.

With a broad portfolio ranging from chemicals and plastics to performance products and crop protection agents, BASF SE is headquartered in Ludwigshafen am Rhein, operates in more than 90 countries and supplies a wide range of industries. The Antwerp site plays a key role in this network as Belgium's largest chemical production plant and the second largest within the BASF Group worldwide. The plant benefits from its strategic location near the Port of Antwerp which enables efficient feedstock and product logistics, and provides strong connectivity to Europe's infrastructure.

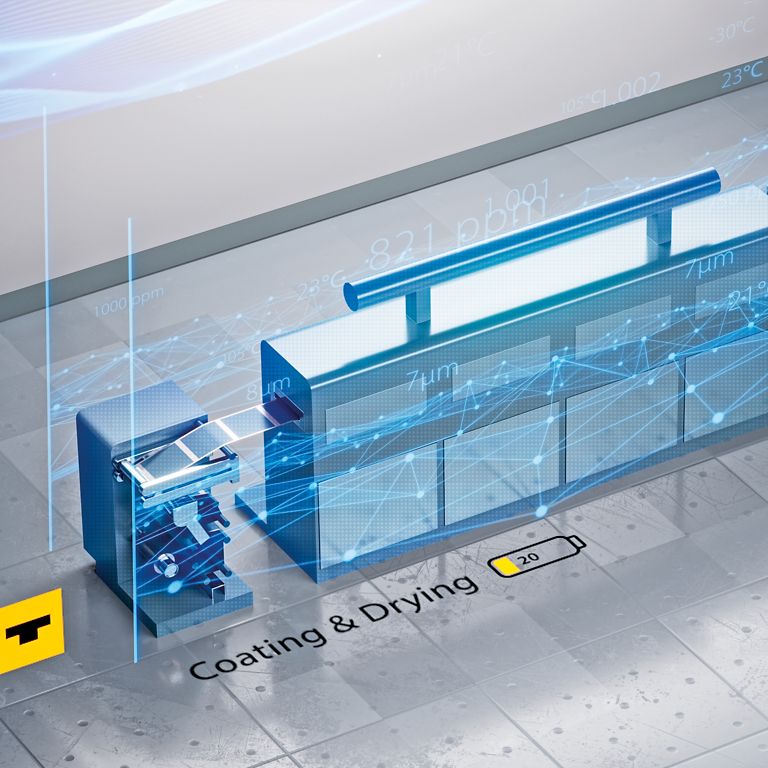

To improve the safety and efficiency of inspection processes in the extensive water treatment plant, BASF uses 'Spot', Boston Dynamics' four-legged inspection robot. Equipped with a wide range of sensors and cameras, the robot performs inspection tasks independently, helping optimize operations and maintain the highest safety standards.

"Fortunately, for this application we were able to rely on the experience of the Turck Multiprox team who quickly concluded that an RFID solution was ideal here."

Tom Delbecque | Projektmanager | BASF

Inspection rounds in the water treatment plant

The water treatment plant is critical for regulatory compliance and reliable operation. In the past, employees had to physically inspect the facilities on a regular basis and measure values at numerous checkpoints to prevent environmental violations and detect emerging technical issues at an early stage. Today, these time-consuming, repetitive tasks are handled by the inspection robot. It performs three inspection rounds per day at 150 checkpoints across eight different routes. During these rounds, data such as pump and motor temperatures, oil levels and potential leaks are captured accurately and reliably. Using artificial intelligence, the robot detects deviations from the target state and automatically triggers an alarm. The robot dog operates around the clock and returns to its station after each inspection round to recharge its battery.

Secure access control using RFID technology

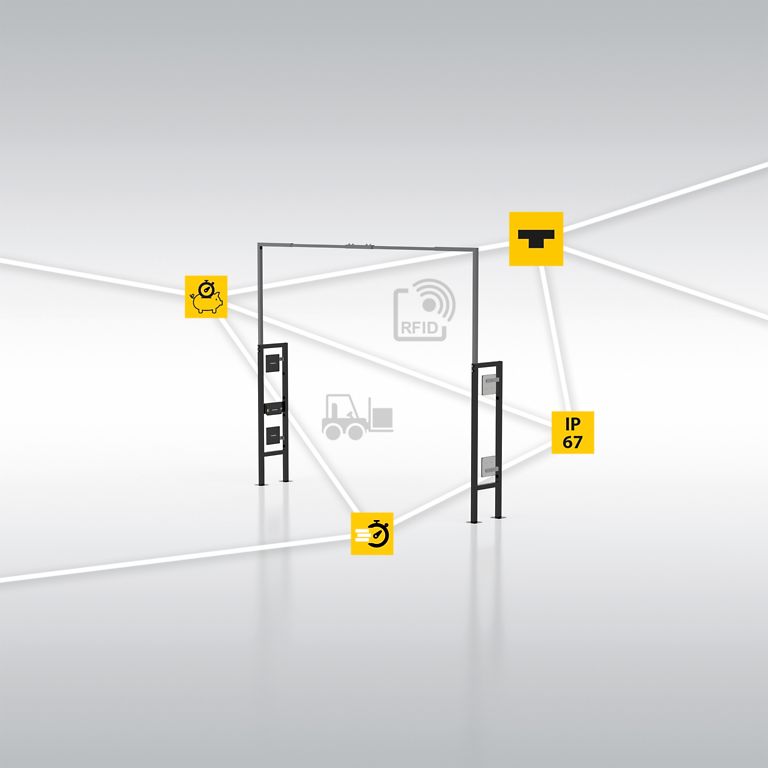

To ensure that the inspection robot always has unrestricted access to the charging area while reliably preventing unauthorized entry, Tom Delbecque, project manager at BASF, set out to find a system that would automatically open the station door exclusively for the robot. The decision was made in favor of a smart RFID solution developed in close cooperation with long-standing partner Turck Multiprox. Alternative approaches such as optical or radar-based systems proved unsuitable because they respond to any movement and could therefore open the door unintentionally. "Fortunately, for this application we were able to rely on the experience of the Turck Multiprox team, who quickly concluded that an RFID solution was ideal here," he explains.

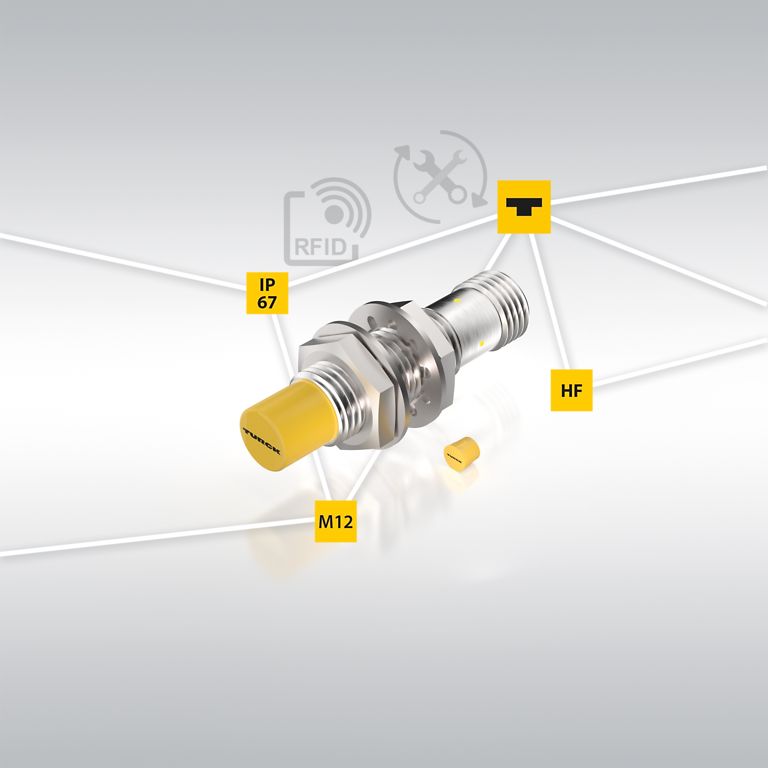

TURCK's TN865-Q120 UHF RFID reader reliably detects the inspection robot at ranges of up to 1.5 meters. For this purpose, the robot dog carries an RFID tag with a unique ID which is read as soon as it enters the reader's detection range. A TBEN-S2 RFID interface with integrated ARGEE logic control continuously sends read requests to the reader so the robot can be identified at any time. Once the robot is identified, the door opens automatically. After the inspection robot docks at the charging station, the TBEN-S2 module initiates automatic door closure to protect the charging station from unauthorized access. Turck Multiprox's system experts created this control logic directly in TURCK's ARGEE programming environment on the TBEN-S2-2RFID interface.

Optimized security and efficiency with RFID technology

The RFID-based access solution is an efficient way for BASF in Antwerp to automate inspection processes. By precisely detecting the robot dog and automatically controlling access, the charging area is reliably protected from unauthorized entry. The robust design of the components used and the high IP67 protection rating also ensure reliable operation in the demanding industrial environment. Especially in times of high demand for skilled labor, this solution shows how companies can use intelligent automation to relieve employees of time-consuming, repetitive tasks without compromising operational safety or environmental protection.

Customer | www.basf.com

Hans De Craemer is a marketing manager | Turck Multiprox in Belgium