Modular conveyor system with decentralized controllers

Self-powered, electric e-Carts from Krups Fördersysteme optimize the assembly and test interlinking in the battery production of a German car manufacturer; TURCK's robust IP67 PLCs control the sequence of individual conveyor technology modules decentrally

Quick read

With its e-Cart system, Krups conveyor systems respond to the increased requirements of modern assembly and test automation in terms of safety, maintenance-free operation and communication. A maintenance-free running rail and intelligent, driven carriages, bundled with decentrally controlled standardized system components, ensure flexible and safe assembly automation. This increases availability and enables flexible processes with minimal batch sizes. The individual modules of the line are controlled autonomously by TURCK's TBEN-L-PLC. With the multibus-capable IP67 PLC, Krups offers standardized and optimized control processes for the individual components. This allows customers to reduce wiring and commissioning time and easily expand the system.

In many places, automobile manufacturers' or Tier 1 suppliers' production halls work like clockwork. At the individual stations, robots and employees devote themselves to closely timed work steps in order to then guide the processed object back into the process flow. However, if a gear wheel jams, the entire production process comes to a halt, particularly if that gear is part of the production conveyor system.

Maximum availability and flexibility are at the top of the customer requirements list. This puts conveyor technology manufacturers under pressure to innovate. The goal is to provide maintenance-free and more flexible conveyor systems that are easier and faster to integrate, and which, after deducting all direct and indirect costs, are available at best at a lower price and faster than alternative solutions.

With its main plant in Dernbach, Rhineland-Palatinate, Krups is one of the market leaders in assembly and test automation. The company specializes in automation systems that efficiently connect assembly and test stations. The new e-Cart system enables the implementation of actively powered, intelligent workpiece carriers that can rotate, lift, clamp, or tilt workpieces.

Krups' recent development is a high-availability conveyor system that is taking, or driving on, completely new paths. , second-generation head of the company, explains the basic idea: "In a classic roller conveyor system, the drive is located in the conveying system. We have a lot of mechanical stress on the line, which also results in corresponding wear. Maintenance is therefore always a problem with permanently installed systems. That's why we wanted to turn the system around and eliminate maintenance. So we have developed a passive line that is completely maintenance-free. All the technology and electrics are now in the carriages, the so-called e-Carts. These electrically powered vehicles are equipped with a self-diagnosis system and can be removed for maintenance as a precautionary measure if required. As a result, the service life is reduced and the line remains in operation. In addition , it is also very easy to extend the conveyor line at a later date. The e-Cart system also enables more flexible production processes to be mapped with smaller batch sizes. It could also be said that it is an Industry 4.0 promoter."

e-Cart revolutionizes conveyor technology for e-mobility

Krups has introduced the new conveyor system under the name "LOGO!MAT e-Cart". And who, if not the automotive industry, should be one of the first adopters of this material handling technology, given that the automotive industry is known as an early adopter of industrial automation. A home game for Krups, the company makes about 95 percent of its sales in the automotive industry. The customers of Westerwald are partly integrators who supply complete systems for automobile manufacturers, or even the integrators of the automobile manufacturers themselves. For example, a large German automobile manufacturer will use an e-Cart system in its battery production for electric vehicles in the future.

To avoid having to reinvent the wheel with every system, Krups relies on a modular concept. The system consists of a few standardized modules: rotary modules, transverse shuttle, stopper and indexer. These units are individually compiled to meet the customer's requirements and connected to the plant control system on site. The conveyor system provides the customer's production system with report data and enables bidirectional communication interfaces.

"However, running cables for 24 V and signals to the 12 controllers on the stoppers and labeling them would be very time-consuming. That alone would easily cover the cost of the TBEN-L-PLC."

Christian Mies | Steuerungsentwickler | Krups Fördersysteme

Decentralized controller for modular conveyor system

"In the past, there was always a main controller to which all signals were routed. In some cases still in point-to-point wiring, but increasingly with decentralized I/O units. The problem was the programming. Traditionally, a system programmer programs everything in one step sequence. However, if any condition occurs at the time of switch-on or after an emergency start that is not mapped in this step sequence, then the users would have to move units manually in order to have a known picture again," explains Christian Mies, controller developer at Krups. "To avoid manual intervention, a conveyor system must be programmed differently. You create conditions and define responses that are suitable for all situations." If the control of the modules takes place in the overall controller, customers sometimes make changes here that disrupt the overall process. If faults occur as a result, they fall back on Krups – even though the company was not responsible for them. This experience has taught Krups one thing: Ideally each module controls itself independently.

Autonomous control increases process reliability

Today, each module acts externally as a black box, which communicates with the main system controller only via a bus connection in both directions. In doing so, the module performs its intended functions: rotating, lateral shifting, monitoring traffic, and reporting its status. Thus, each module – precisely tailored to the development – is controlled and perfectly reproduces all possible processes. Above this is a system controller that controls the entire flow. However, the actual motion sequences and condition monitoring are performed by each controller on the module.

For example, Krups does not have to intervene in the control system of the entire plant, nor does the plant operator have to control the conveyor system modules. Only the communication between the overall control system and the modules has to be implemented at a basal level. These conveyor technology modules, which have their own intelligence, are called smart modules internally by Krups. Ten years ago, the company was already looking for autonomous controllers that could be mounted directly on the modules in the field.

"In the longer term, we not only want to be a supplier of mechanics, but also a supplier of plug and play conveyor systems, i.e. smart systems whose components control themselves and only require a master control system."

Philipp Krups | Geschäftsführer | Krups Fördersysteme

In-house IP67 controller

"We were already looking for small controllers with IP67. But there was nothing on the market," reports Christian Mies. So Krups initially helped themselves: "We had our own controller built on a PCB, attached all M12 connectors and put everything in one housing. This housing had to be drilled, plus pneumatics and display. These were very large boxes, relatively complex to produce. We had to have the PCBs manufactured, assemble the housings and wire everything. That worked, but it was cumbersome," senior manager Peter Krups explains the path to in-house module control.

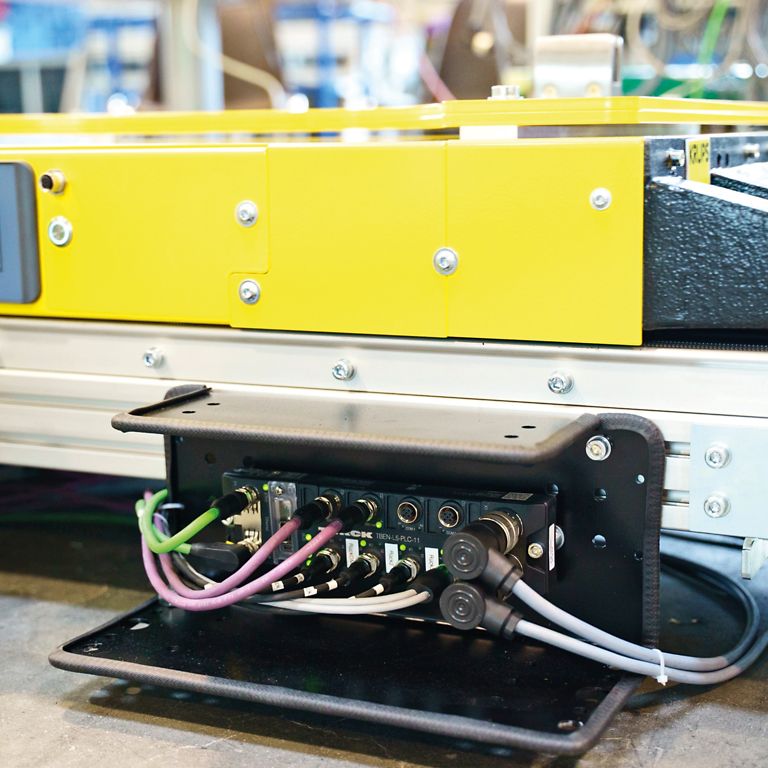

Since TURCK introduced its TBEN-L-PLC block controller a few years ago, Krups has been able to dispense with the complex in-house development. Today, the company uses the IP67 controller in many machine models – not just in the e-Cart system. The controller for each conveyor system element was written with Codesys. Communication with drives or valve clusters and other components of the module occurs via a bus interface, while communication with the main controller of the entire system usually occurs via Profinet. “We have the advantage that the modules are identical and can be used without an additional field programming device, making it easy to exchange, insert, and back up data. Ideally, the customer only needs to connect the 7/8-inch plug for 24 volts and the Ethernet plug for the bus connection," says Mies, explaining the benefits for the users. According to IT manager Mies, the variety of protocols used by the compact controller also has its advantages for an internationally positioned company like Krups: "We have the American market with EtherNet/IP, as well as the European and Asian markets, where the protocols are mixed. We are currently focusing on EtherNet/IP and Profinet, but Modbus TCP would also be possible in principle if a customer wanted it. The nice thing is that the TURCK device contains all the licenses of Codesys. No matter what the customer has for a fieldbus, the license is included and we can use it. We can even use it if we need a small main controller because the master licenses are also included," says Mies, describing the different application scenarios of the TBEN-L-PLC.

e-Cart system saves power in battery production

The dimensions of the e-Cart conveyor system in battery production already make it clear that the manufacturer is serious about e-mobility. With 130 self-propelled carriers on one kilometer of conveyor track, the stage of small series production has been left behind. On the track , Krups installed 70 rotary tables and around 140 stoppers. 10 stoppers use a TBEN-L-PLC together as a gateway to the customer's main controller. This significantly reduces the number of bus participants for the customer.

To change the direction, the carriages are steered by transverse sliding units on parallel tracks or changed in their direction of movement via rotary tables. In contrast to most traditional systems, communication with the trolleys of the e-Cart system is possible. Near Field Communication (NFC) units are located on the stoppers to exchange data via the TBEN-L-PLC as a gateway between the main control unit and the carts, allowing carriages to be ejected at an early stage, depending on their status or pending warning messages. Another advantage is that when the carriages are serviced, you do not use any electricity – unlike conventional roller conveyor systems, in which the drives usually pass through – even if no box has to be moved.

BL compact provides additional I/Os via CAN

The sensors and actuators of the individual modules are directly connected to the TBEN-L-PLC. The block controller provides eight universal channels on four female connectors, which automatically adjust to the required configuration as input or output. If additional I/Os are required, Krups expands the number of signals required with the BL compact I/O modules via the CAN bus connection. The BL compact modules are also designed in IP67 and are mounted directly on the units.

IP67 saves wiring work

Krups has recognized the work saved by using IP67 technology. "Just running cables for 24 V and signals to the 12 controllers on the stoppers and labeling them would be very time-consuming. That alone easily covers the cost of the TBEN-L-PLC," estimates IT manager Christian Mies.

The e-Cart system is not only energy-saving and more fail-safe, it also enables more flexible processes, as outlined in Industry 4.0 model scenarios and as has already been implemented. Communication with the workpiece carrier allows for a higher degree of product variance to be represented, as another application example shows: The e-Cart conveyor system also transports vehicle axles of two models in the automotive industry. Nevertheless, there are 140 different types of axles that drive the carts through production. The actively driven workpiece carriers allow different production steps to be easily controlled or omitted. Waiting times are minimized and different speeds can also be assigned to the carts at the stations.

With its smart control technology in the field, the e-Cart system contributes to the smooth and efficient operation of even flexible production processes. In view of this, it becomes clear that the image of production as well-timed clockwork comes from a different time. Even if one gear wheel engages in the other in production 4.0, the clocks of production 4.0 must be flexible, like Salvador Dali's clocks.

Customer | www.krups-online.de

Frank Paluch is a sales specialist at TURCK