Modular plant solutions shorten time-to-market in the pharmaceutical industry

Able to reduce time- to- market in the pharmaceutical and biotech industries in the same way as machine manufacturers and integrators

Quick read

In many industries, modularization and standardization are seen as effective strategies to reduce costs, and production, delivery and development times. This is a particular point of interest in the biotech and pharmaceutical industries due to the time pressures caused by approvals and patent protection. Components that automatically adapt to the customer's requirements are a method of dealing with conflicting interests between customer requirements and standardization. TURCK supports this approach with its multiprotocol Ethernet I/O and control system components. With the three Ethernet protocols, Profinet , EtherNet/IP and Modbus TCP, the devices reach a broad range of control systems used on the market, which helps to maintain company standards and still meet the preferences of the global pharmaceutical manufacturers.

Since before the COVID-19 pandemic, companies in the pharmaceutical and biotech industry have been faced with the challenge of developing, approving and producing active ingredients on a large scale as quickly as possible. Speed is of the essence because patent protection for a drug expires after 20 years. Revenue from products based on the patent, however, only lasts for a part of this time because it typically takes a number of years to move from the patent grant to the marketable product. It is therefore important to have products available on the market as soon as possible following the approval of a drug. The entire process from development to saleable product in pharmacies usually takes around twelve years. Companies must start setting up their production capacity before the drug is granted final approval. If the approval is not granted, the company will simply be left with the production facilities and must reconfigure them at a cost of millions of euros.

However, it is more common for plants to be unable to start production directly following the approval of a grant due to delays in the construction of the production line. As a result, the drug goes into overtime, which comes at a great cost. Those involved in integration and plant construction hope to find a way out of this dilemma—or at least achieve a less severe outcome—by rapidly expanding production capacities. The unique design of most plants also results in overly long engineering, commissioning and testing times.

Standardization reduces time- to- market

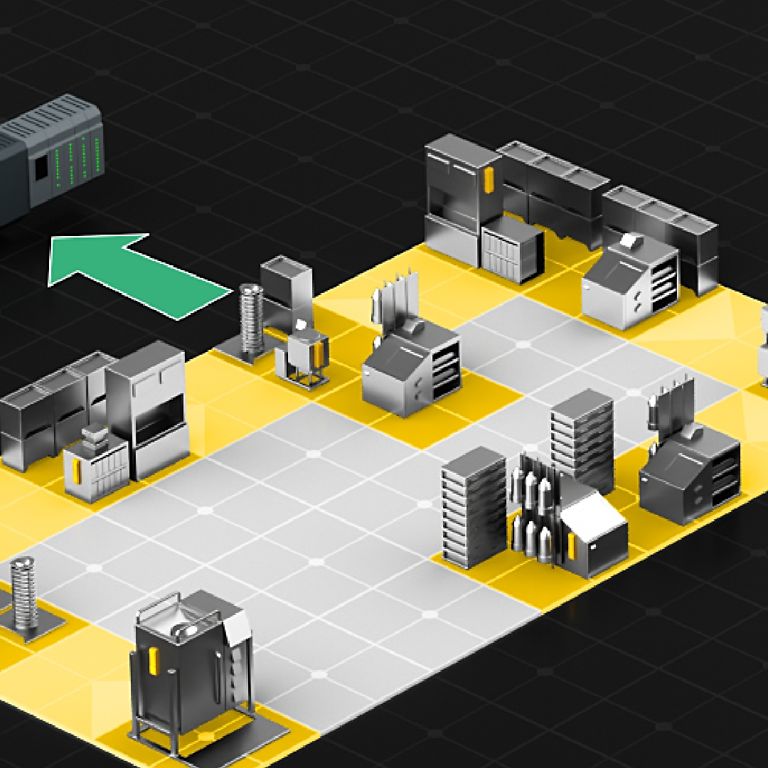

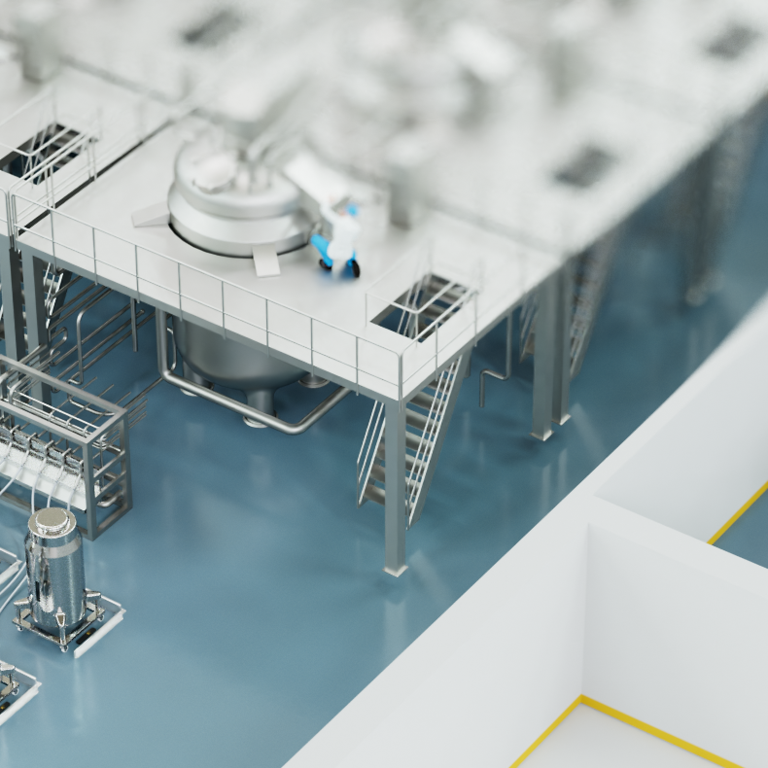

Modular plant concepts aim to accelerate and improve the planning of these project phases. Many plant components or machines in the biopharmaceutical industry can in principle be standardized—from upstream bioreactors and filtration units to midstream centrifuges, microfiltration and ultrafiltration units, all the way down to the downstream process. By combining all of these units, such as blocks with standardized interfaces, into a complete system, engineering, actual production and commissioning times can be significantly reduced.

Different end-customer network protocols often create barriers for standardization and modularization. They usually require the use of different I/O components, actuators and sensors, which in turn increases expenditure in engineering, e-planning and, ultimately, in warehousing.

With its multiprotocol Ethernet I/O and control modules, TURCK offers efficient solutions without the need for user intervention in Profinet , EtherNet/IP or Modbus TCP. The devices themselves recognize which protocol is used on the network and adapt to it. The machine manufacturer can therefore install devices of this standard independent of the end customer's network.

Offline tests shorten commissioning time

Machine manufacturers achieve further acceleration via the testing of machine modules and skids that are already in their own production area. Thanks to the integrated TBEN-I/O module control functions, Factory Acceptance Tests (FAT) can even be carried out offline, without connecting to downstream system control modules. Due to their integrated ARGEE logic software, TURCK's I/O components enable the simulation of live operations by emulating the inputs of connection machines. If I/O modules with ARGEE are not a viable option, TURCK offers a complete control system programmable with CODESYS 3, which includes an IP67-rated TBEN-PLC controller and supports the three protocols in the multiprotocol standards.

IP67 components and quick connectors reduce wiring costs

The high degree of protection provided by the TBEN family also accelerates plant commissioning. Thanks to IP67 protection, the construction and wiring of large control cabinets can be minimized. In conjunction with quick connectors, only process connections, power supply and network cables need to be connected on site. Realistically, not all components are always available with IP67 protection, but control cabinet construction is significantly minimized or can be largely preassembled. With TURCK's new IP67-rated PSU67 power supply units, switch cabinets are no longer required to provide a power supply.

Multiprotocol I/O systems for all zones, degrees of protection, levels of availability

The TURCK multiprotocol device product series has expanded over the years. For example, customers who want the flexibility of a modular system will find these system solutions for installation in control cabinets or directly in the field with BL20 and BL67. If I/O blocks are required, TURCK offers devices for cabinet-free installation directly on the machine via the TBEN family, or I/O blocks for installation in protective housings via the FEN20 series.

If an application in hazardous areas requires maximum availability and configuration options during operation, users can select a system from the excom product series, which also supports the three multiprotocol networks with the latest Ethernet gateways; both as a system for installation in Zone 2 and as an N-series for installation in the safe area.

Modbus TCP as a parallel channel for diagnostic data

The multiprotocol capabilities of the devices offer further benefits in addition to the reduced number of variants, and simple standardization and modularization: The devices can also be used for data access in parallel to Ethernet communication via Profinet or Ethernet/IP using Modbus TCP. Through this channel, user and analysis data can be easily branched off in outsourced IT systems and evaluated independent of plant operations for diagnostics and monitoring purposes.

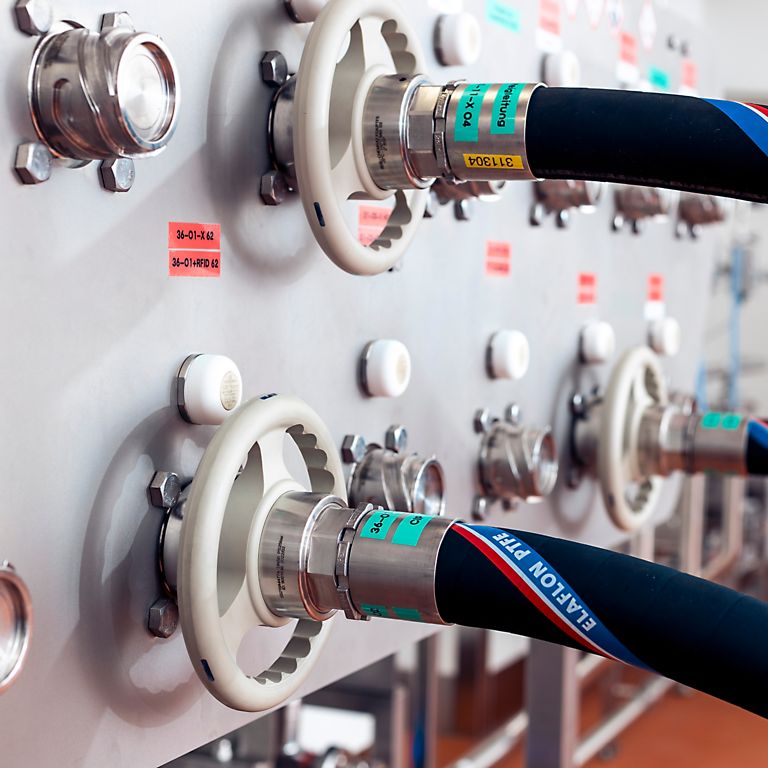

IO-Link and RFID for automatic identification of skids

Particularly for mobile units that are in use at different points in the plant system, and also usually specified according to certification guidelines or laws, it is advisable to document when and where they have been used. IO-Link or RFID makes the tamper-proof identification and documentation of the usage of machine modules simple but reliable. If the modules use IO-link components anyway, the full machine may be identified using the application- specific tag for these components. IO-Link can also be used to communicate diagnostic data for predictive maintenance. Many components already offer this option ex works without the need for complex programming. An increase in device temperature or a reduction in signal strength indicate premature wear, contamination or other problems. If there are no IO-Link components in use, RFID tags may be used to identify the modules using their UID. The UID is a unique, one-time identification number for the tag that cannot be changed after production. For identification in explosion-protected areas, TURCK is the only manufacturer on the market that offers Ex-e protection class RFID read/write devices that can be used directly in Ex zone 1/21 without a protective housing.

Modbus TCP as a parallel channel for diagnostic data

The multiprotocol capabilities of the devices offer further benefits in addition to the reduced number of variants, and simple standardization and modularization: The devices can also be used for data access in parallel to Ethernet communication via Profinet or Ethernet/IP using Modbus TCP. Through this channel, user and analysis data can be easily branched off in outsourced IT systems and evaluated independent of plant operations for diagnostics and monitoring purposes.

IO-Link and RFID for automatic identification of skids

Particularly for mobile units that are in use at different points in the plant system, and also usually specified according to certification guidelines or laws, it is advisable to document when and where they have been used. IO-Link or RFID makes the tamper-proof identification and documentation of the usage of machine modules simple but reliable. If the modules use IO-link components anyway, the full machine may be identified using the application- specific tag for these components. IO-Link can also be used to communicate diagnostic data for predictive maintenance. Many components already offer this option ex works without the need for complex programming. An increase in device temperature or a reduction in signal strength indicate premature wear, contamination or other problems. If there are no IO-Link components in use, RFID tags may be used to identify the modules using their UID. The UID is a unique, one-time identification number for the tag that cannot be changed after production. For identification in explosion-protected areas, TURCK is the only manufacturer on the market that offers Ex-e protection class RFID read/write devices that can be used directly in Ex zone 1/21 without a protective housing.

André Ammann, Key Account Manager for Pharma Europe at TURCK