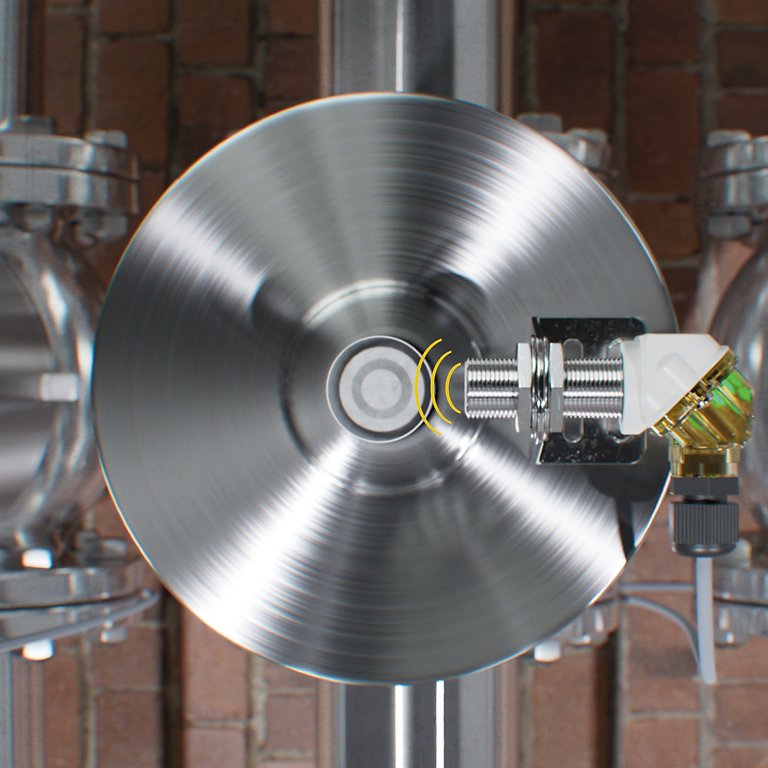

Fast sensor replacement in beverage production

Pull like a plug: Thanks to the uprox + WDTC with terminal chamber connection, the sensor can be replaced without the need for a specialist

Benefits

Easy commissioning and maintenance of the system thanks to removable terminals

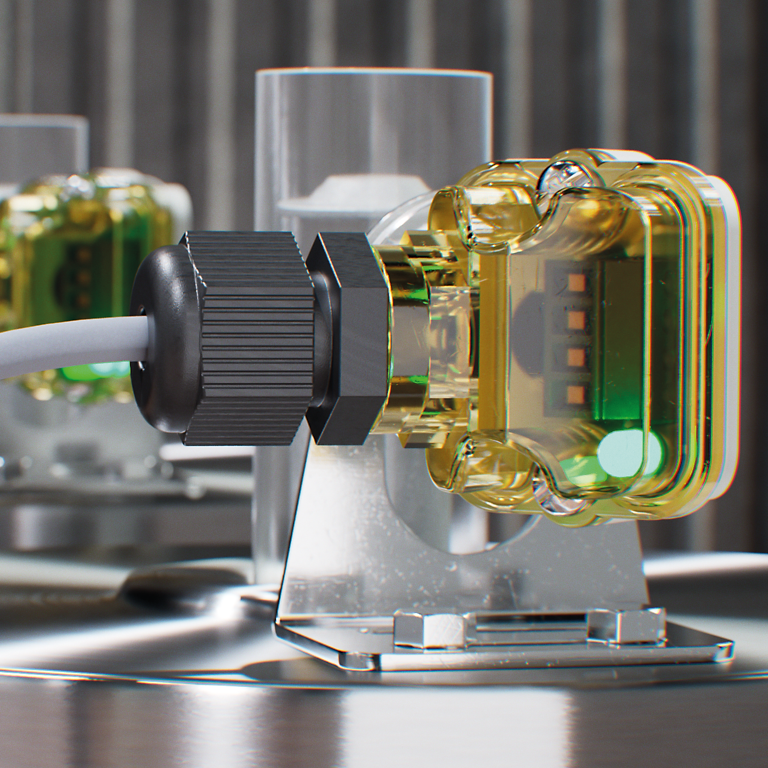

High degree of leaktightness and resistance to chemicals

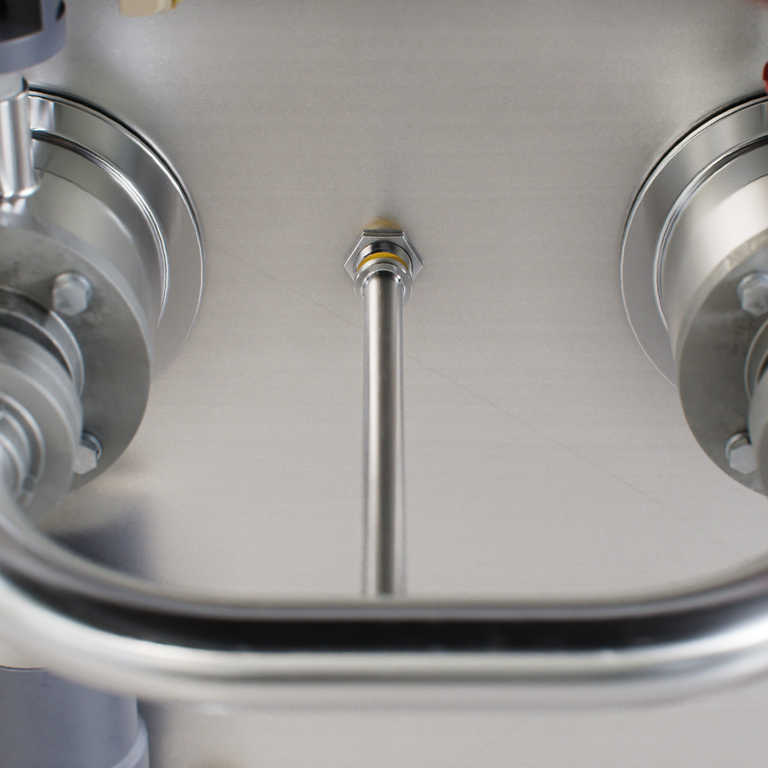

Increased switching distance on all metals

Challenge

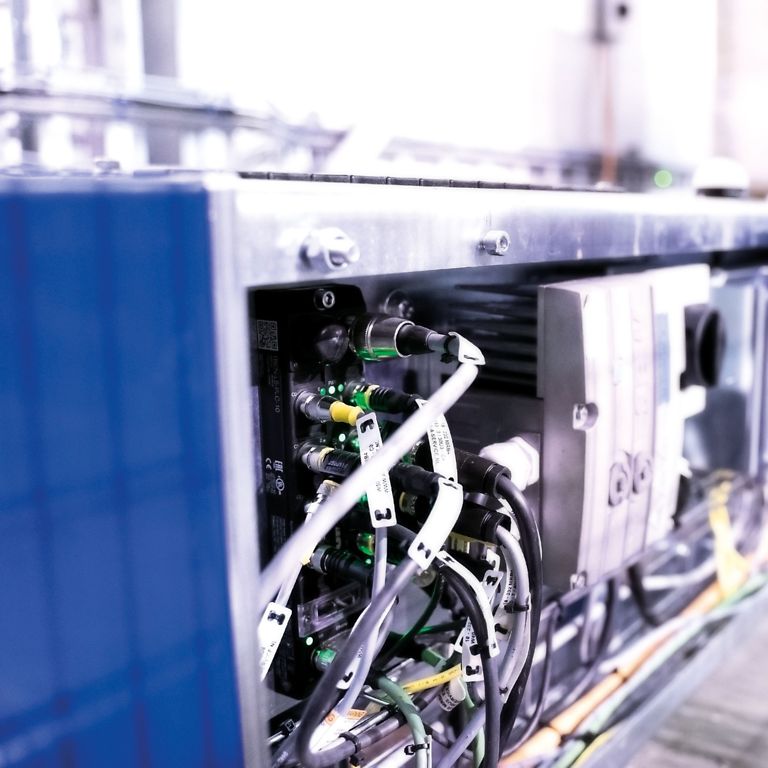

When sensors or valves with sensors are replaced or removed for maintenance in the food industry, the electrical connection is disconnected and then reconnected. Conventional sensors with terminal compartments require a specialist for the wiring process, which increases downtime. Since qualified personnel are not always available on site, a solution is needed that allows sensors to be replaced without electrical expertise in order to minimize production downtime and reduce maintenance costs.

Solution

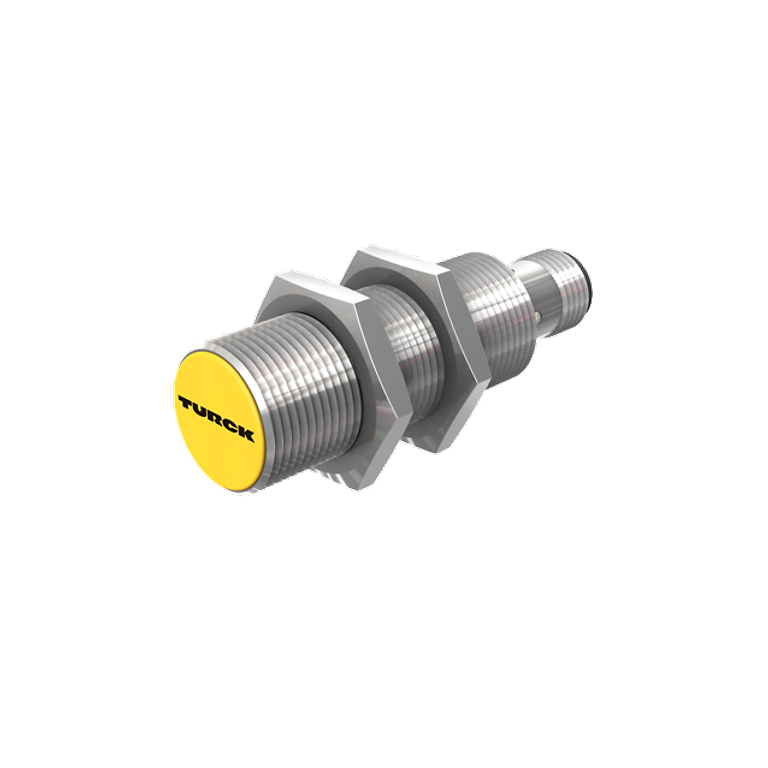

The uprox + WD sensor from TURCK with terminal compartment connection allows for quick, tool-free replacement without the need for specialist personnel. Instead of disconnecting and rewiring each individual wire, the terminal block can simply be pulled out of the old sensor and inserted into the new one – similar to a plug connector. This significantly speeds up maintenance and prevents unnecessary downtime.

The sensor also offers a high degree of protection and chemical resistance, making it ideal for use in the food industry. Due to the increased switching distance for all metals, the uprox + WDTC can be used flexibly in a variety of applications without the need for shielding measures. This solution makes the maintenance of production facilities more efficient and cost-effective, while also increasing operational safety.

"The uprox + WDTC supports tool-free sensor replacement, simplifying maintenance and minimizing production downtime.“

Sander Makkinga | Director Product Management Position/Proximity Sensors | TURCK GmbH