Identification of chocolate molds

Chocolate molds with RFID technology control their own production, reducing energy consumption and waste

Benefits

- Automatic control of pouring and cleaning processes

- Reduction of waste and energy consumption

- Seamless traceability of each individual mold

Challenge

In industrial chocolate production, molds need to be efficiently controlled, cleaned and tracked to minimize waste and improve product quality. Traditional identification and process control procedures are prone to errors and require manual intervention. An automated solution ensures that each mold is correctly filled, and cleaned, and discarded if problems occur repeatedly.

Solution

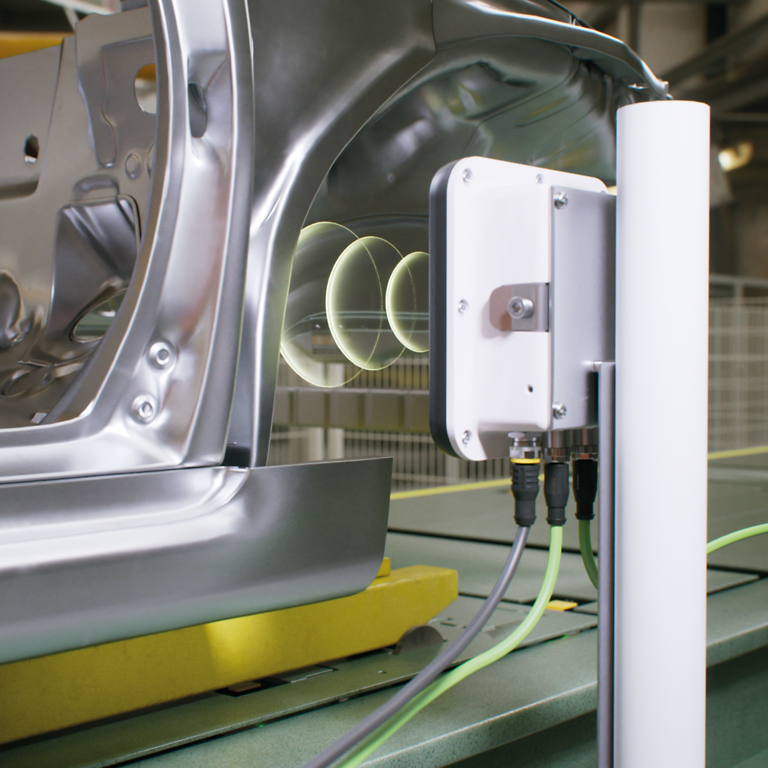

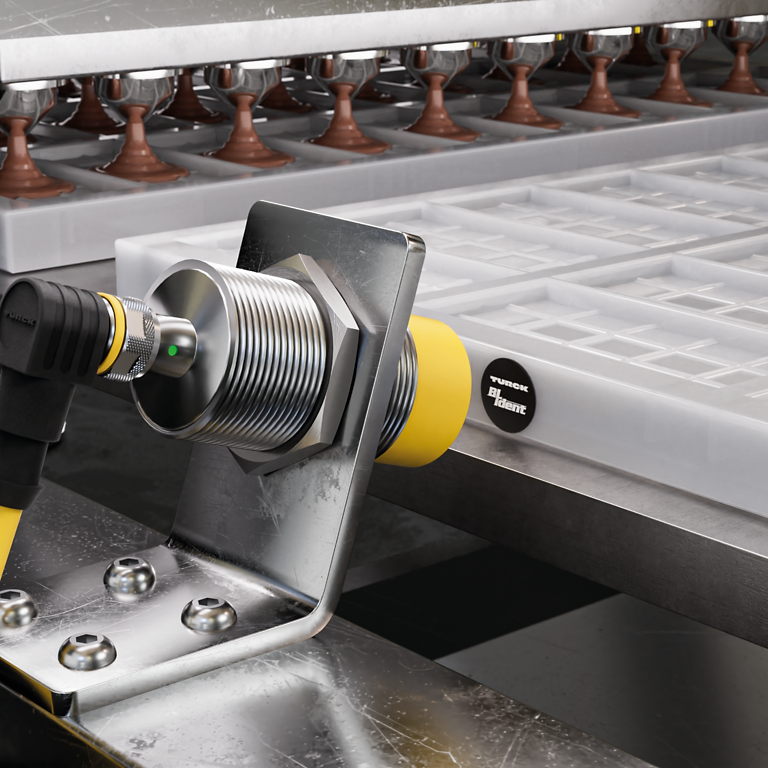

The RFID system from TURCK enables intelligent production control by equipping each chocolate mold with an RFID tag. These tags contain all relevant information about the mold, such as the filling quantity, cleaning specifications and production history. As soon as the mold reaches a station, the RFID system reads out the stored data and gives the pouring machine instructions for how to fill the mold correctly. At the same time, incorrectly filled molds are automatically detected and rejected.

After production, the system also controls the cleaning process by sending the cleaning system the optimal settings for the respective mold. Molds that have been detected with multiple errors can be specifically removed from the production cycle to further increase process reliability.

„ With RFID, chocolate molds can control their own production path – to achieve less waste and consistently high product quality.“

Thorsten Enthöfer | Product Manager RFID HF Systems | TURCK GmbH

Learn more about our products