IO-Link solution reduces commissioning time for filling machines

Elopak relies on IO-Link and ultra-compact block modules from TURCK for its new Pure-Fill filling machine platform – significantly increasing commissioning speed, flexibility, and cost efficiency

Quick read

Elopak develops and produces bottling machines for beverage cartons in Mönchengladbach. The packaging specialist uses IO-Link as the basic technology to automate its new Pure-Fill machine platform. Key factors in selecting TURCK's Ethernet and network components were their flexibility, ease of wiring, and seamless integration into Profinet Engineering. The ultra-compact multiprotocol I/O modules TBEN-S2-4IOL, -4AI, and -8DXP, as well as the Ethernet switch TBEN-LL-SE-M2, were particularly impressive to the planners at Elopak .

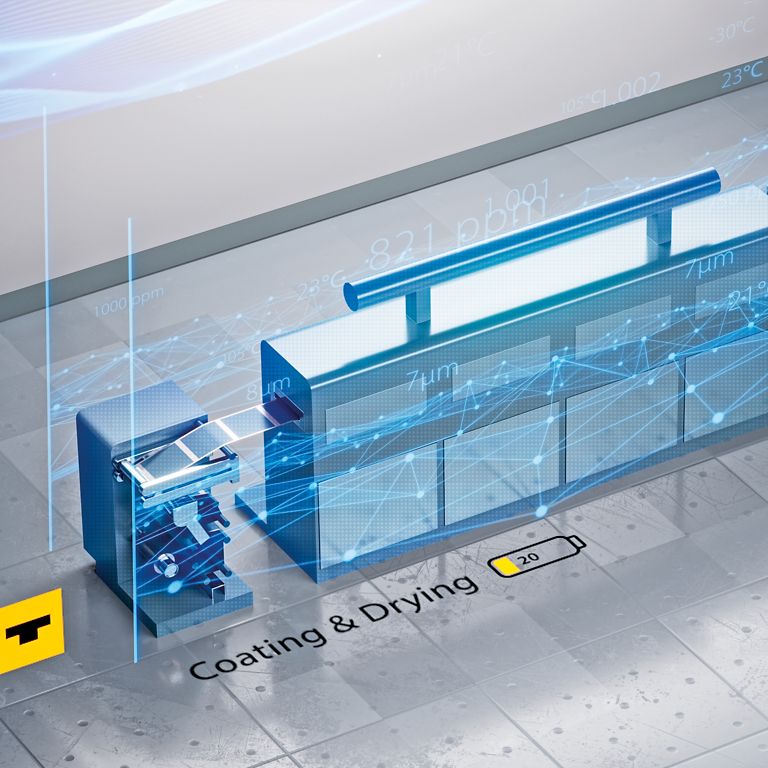

Everyone has probably held one in their hands at some point: the "Pure-Pak" beverage carton from Elopak. As one of the world's leading system providers of carton packaging and filling machines, Elopak, based in Spikkestad, Norway, offers innovative packaging solutions made from renewable, recyclable, and sustainably sourced materials. The German subsidiary Elopak GmbH develops and manufactures filling machines at its Mönchengladbach location. The highly specialized systems unfold the carton, dose the liquid, and fill it aseptically before sealing the beverage cartons airtight at the end. The systems can clean themselves without dismantling. The beverage cartons are filled directly at the installation site of the system in compliance with the highest hygiene standards.

New generation of machines with a wide range of applications

The new Pure-Fill machine platform, based on its predecessor, the E-PS120 A, should be particularly flexible in terms of adapting to customer requirements. "Our primary goal was to create a modular machine that could be easily adapted to specific customer requirements while maintaining the same overall design," explains Horst Klesse, Electrical Design Manager, Product & Development at Elopak. The new filling machine platform must be flexible in order to cover a wide range of applications – beverages with low acidity such as milk or those with high acidity such as fruit juices, in different volumes such as one- or two-liter cartons, at filling speeds of up to 12,000 beverage cartons per hour and production on two to five lanes.

"The compact TBEN-S2 devices from TURCK prove to be the ideal solution for our application, as there are no comparable alternatives."

Horst Klesse | Manager Electrical Design, Product & Development | Elopak

More flexibility with the same footprint

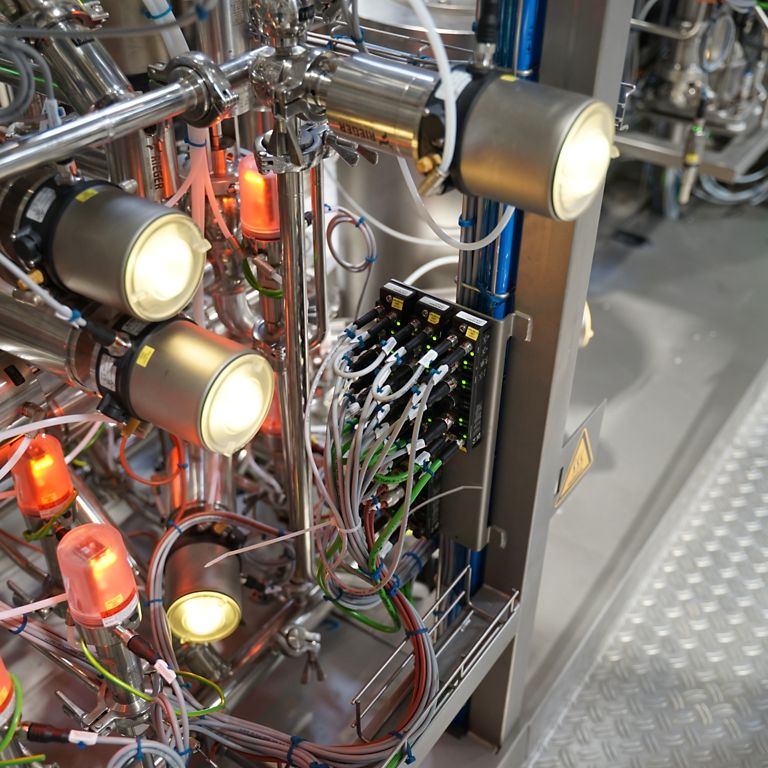

When integrating IO-Link into the machine platform, the overall size of the plant should remain the same despite the greater flexibility. Elopak used IO-Link in some cases in the predecessor machine to reduce the wiring and commissioning effort. There, IO-Link was used in the so-called process node, which is located on the top of the machine and controls all media and product flows with 34 IO-Link-capable valve heads. Thanks to IO-Link, only eleven cables had to be connected to the control cabinet instead of the original 375 single wires and 73 cables in the process node. "In the new platform, we now wanted to use IO-Link consistently throughout the entire machine, but the size of the master modules previously used was a problem," says Horst Klesse, describing a challenge in development. "Devices without an IO-Link connection also had to be integrated into the system."

Communication problems when controlling the valve heads posed another challenge to the team. "Up to now, this has led to considerable additional effort for the software engineers during programming and commissioning," says Klesse. "As a consequence, we were looking for an alternative solution." In addition, the M12 supply lines of the IO-Link masters used to date were too rigid due to their diameter to connect modules placed very close together.

Ultra-compact IO-Link master: space-saving and combinable design

The solution was the TBEN-S2-4IOL, TBEN-S2-4AI and TBEN-S2-8DXP multiprotocol I/O modules and the IP67 8-port Ethernet/IP-Switch from TURCK. With a width of just 32 millimeters, the ultra-compact TBEN-S2 devices are ideal for systems with limited space. This means that module groups can be easily mounted at a wide variety of locations in the plant – even directly on the profile rails. The use of smaller M8 connectors and thinner cables allows easy connection – even if the modules are mounted directly next to each other and connected with small bridges. "In addition to the compact design, the requirements for the optimal IO-Link master for the filling machine platform were multi-protocol capability, M8 power supply, PROFINET connectivity, as well as suitable connection options and a wide range of mounting options," explains Klesse. "The TBEN-S2 modules from TURCK meet these requirements best."

The TBEN-S2-4IOL master module has four Class-A IO-Link ports and digital I/Os. Despite its compact form factor, it offers a wide range of communication options and, thanks to TURCK's "Simple IO-Link Device Integration" SIDI, it enables the smooth integration of IO-Link devices in PROFINET engineering without the need for additional software. Up to four sensors or I/O hubs can be connected via the IO-Link master channels, which enables a total of up to 64 sensors to be connected. The two four-pin M8 Ethernet/fieldbus connections enable flexible communication via PROFINET, EtherNet/IP and Modbus TCP, while the integrated Ethernet switch allows simplified cabling through line topology. The integrated web server facilitates diagnostics and commissioning, which makes the TBEN-S2-4IOL extremely versatile and makes the integration of devices considerably easier.

The identical TBEN-S2-4AI offers a powerful solution for applications that process analog signals. With four analog inputs that can be configured for voltage, current, RTD or thermocouples, the module enables versatile adjustments to suit different requirements. Each analog input can be configured independently, allowing for flexible use. The universal use of these analog modules is unique on the market. Since only one module type is required to process all common analog value types, this also simplifies spare parts storage and ultimately maintenance of the machine. The integrated Ethernet switch simplifies cabling and optimizes communication.

The TBEN-S2-8DXP is TURCK's compact solution for applications that have to process digital signals. With eight universal, digital channels, configurable as PNP input or 2 A output, this module also enables application-specific adaptations. The diagnostic functions of the supply per I/O port and the output diagnostics per channel ensure reliable monitoring and fast error detection. "We can supply the machine with only three small modules that are identical in terms of shape, size and connections," emphasizes Klesse. "This makes it possible to install even simple sensors without IO-Link. In addition, groups of four to six or even more devices can be easily formed in the plant and connected to the thinner M8 cables." As a special feature, the module offers a third switching output on each M12 port, i.e. a total of 12 switching signals. In this way, for example, lights with three segments can be connected and controlled via a standard cable.

The standardized design of the TBEN-S2 modules with regard to their dimensions and connections enables the user to easily replace modules without having to make complex changes to the plant — regardless of whether analog, digital or IO-Link devices are required. "We can mix and combine modules without having to worry about power supply, connections or space requirements," emphasizes Horst Klesse. "This flexibility has greatly simplified our planning and installation. We can simply tell the mechanic how many modules we need without making a prior commitment to a specific type. This enables us to configure plants in an agile and efficient manner."

Installation time reduced by more than 50 percent

One of the biggest advantages of the IO-Link solution is that installation time has been reduced by more than 50 percent and commissioning time by around 30 percent. This significant time saving not only reduces production time, but also the overall costs. Offline parameterization of IO-Link devices directly from PROFINET engineering greatly simplifies commissioning and eliminates time-consuming manual settings for sensors and actuators. Maintenance is also significantly simplified: Since all device properties and parameters of masters and devices are located directly in the central project repository of the control system, automatic device replacement is also possible in the event of damage – both for IO-Link masters and devices.

Outlook

Elopak has been able to significantly increase the efficiency and flexibility of its machines through the consistent integration of IO-Link technology. Rapid commissioning and simple device configuration improve competitiveness and profitability. In addition, the machine platform is now equipped for future predictive maintenance solutions. "The decision to cooperate with TURCK has proven to be absolutely right," says Horst Klesse. "We were impressed by competent partners and reliable support, as well as the handling of the modules and the wide range of options. The compact TBEN-S2 devices from TURCK have proven to be the ideal solution for our application as there are no comparable alternatives."

Customer| www.elopak.com

Damian Maslowski is a sales engineer at TURCK