Identifikation von Transportbehältern

RFID-System BL ident sichert die Rückverfolgbarkeit von Lebensmitteln

Benefits

- Zuverlässige Erkennung fahrbarer Lebensmittel-Container

- Erhöhte Produktionseffizienz, Qualität und Rückverfolgbarkeit der Lebensmittel

- Für Lebensmittel-Applikationen optimierte Datenträger und Schreibleseköpfe

Challenge

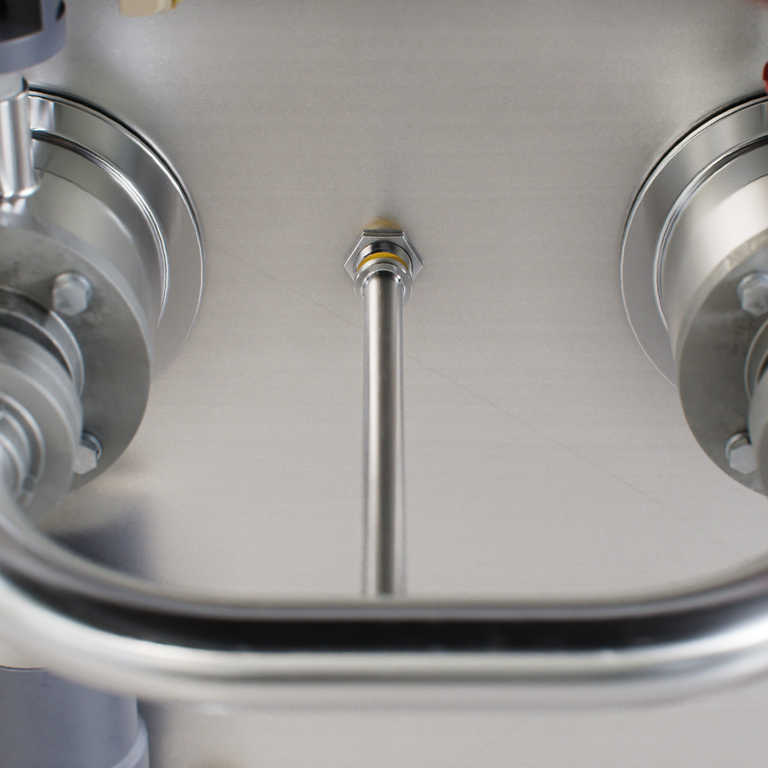

In food production, transport containers and their contents must be clearly identifiable at all times in order to ensure quality standards and traceability. Conventional identification methods such as labels or barcodes can become illegible due to moisture, cleaning agents or mechanical abrasion. A solution is required that functions reliably under the demanding conditions in the food industry and integrates seamlessly into existing automation processes.

Solution

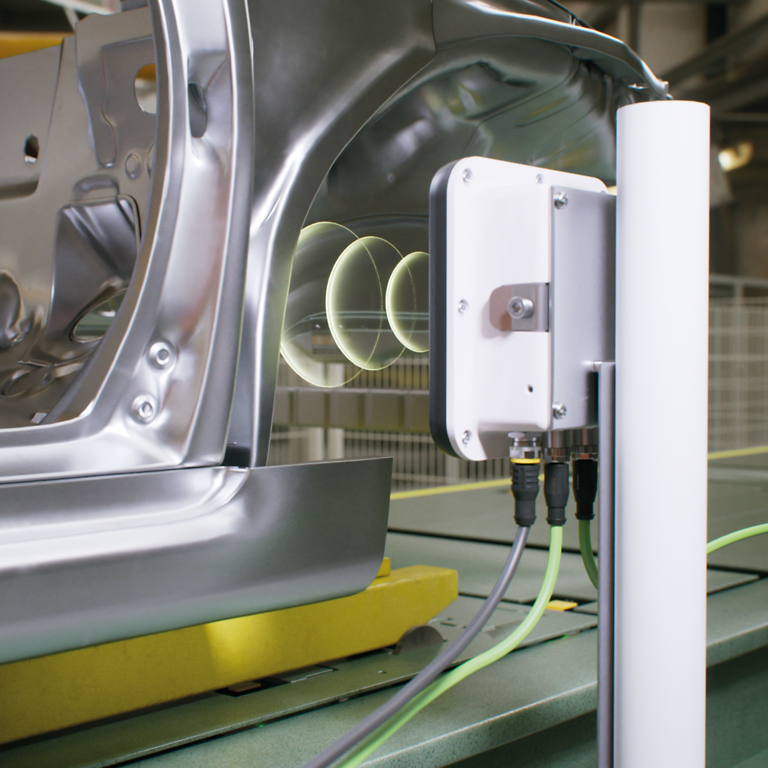

The BL ident RFID system from TURCK enables contactless identification of transport containers and ensures continuous traceability in food production. RFID transponders (tags) are resistant to moisture, heat, chemicals and mechanical load. Since they do not require direct visual contact with the reader, they can also be installed in hard-to-reach areas.

The data on the RFID tags can be updated at any time so that information about the batch, production date or destination can be processed automatically. In conjunction with an ERP system or a control unit, BL ident optimizes the material flow and reduces errors in production. The system also supports complete automation by recording container movements in real time and controlling processes without manual intervention.

"RFID facilitates seamless traceability and makes food production safer and more efficient, even under demanding conditions."

Thorsten Enthöfer | Product Manager RFID HF Systems | TURCK GmbH