Reliable skid detection

Flexible NI40UE Efficiency Line sensors ensure precise skid positioning

Benefits

- Small metal-free zones, magnetic field immunity and factor 1 design make it highly versatile

- Tool-free adjustment of the active surface for quick and easy installation

- Fewer variants reduces costs

Challenge

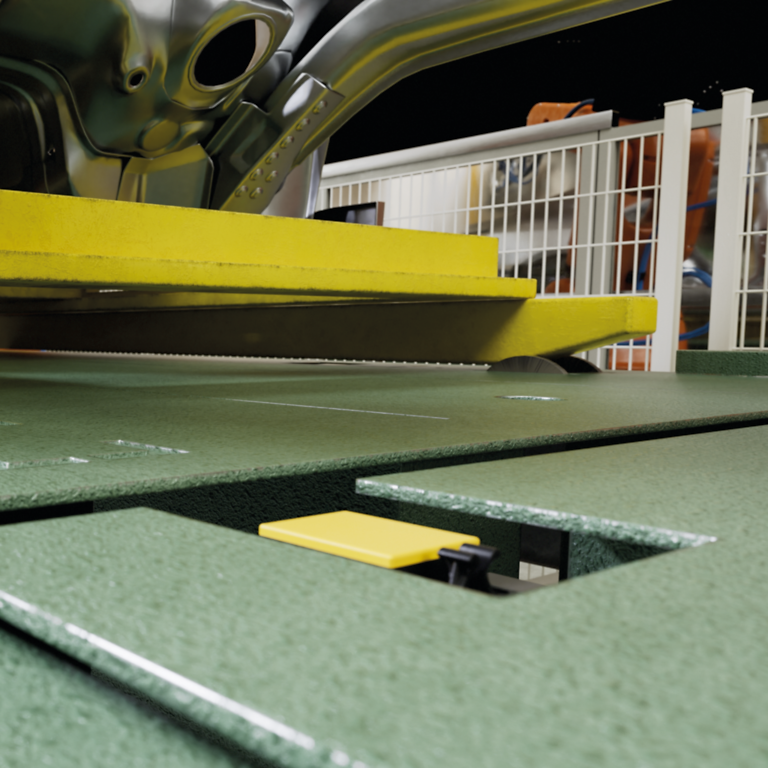

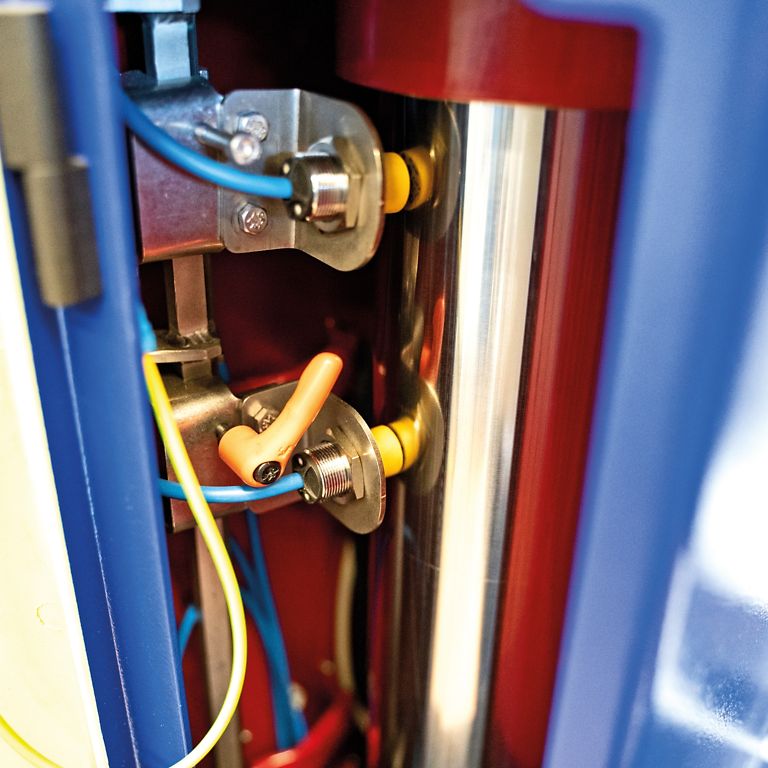

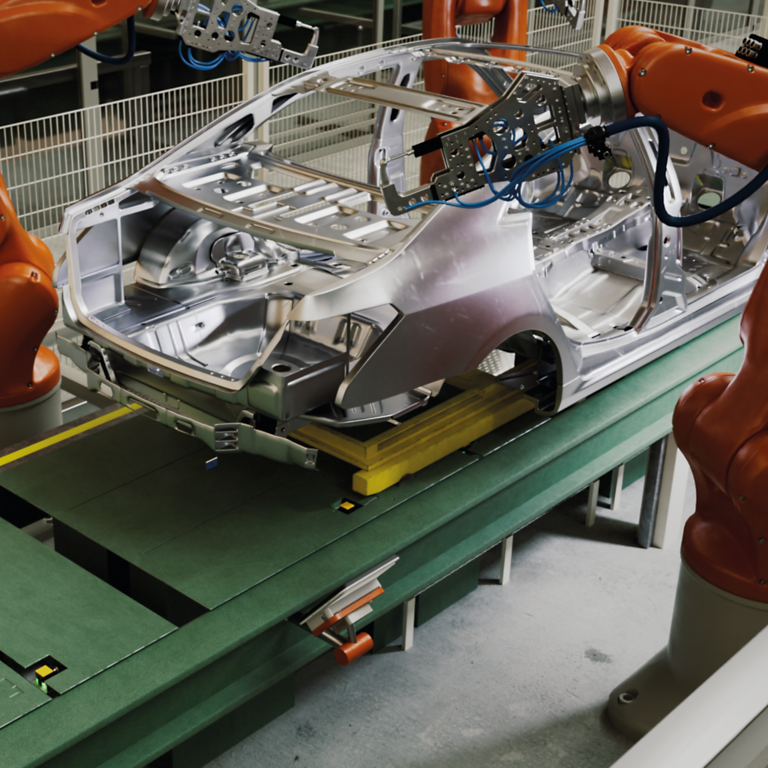

Skid conveyor systems are used to transport workpieces in automotive production. The skids must be reliably detected to help control downstream processes, which requires compact, flexible sensors that are resistant to interference. When installed in confined spaces, the sensors must still offer a high level of precision to avoid downtime or incorrect positioning.

Solution

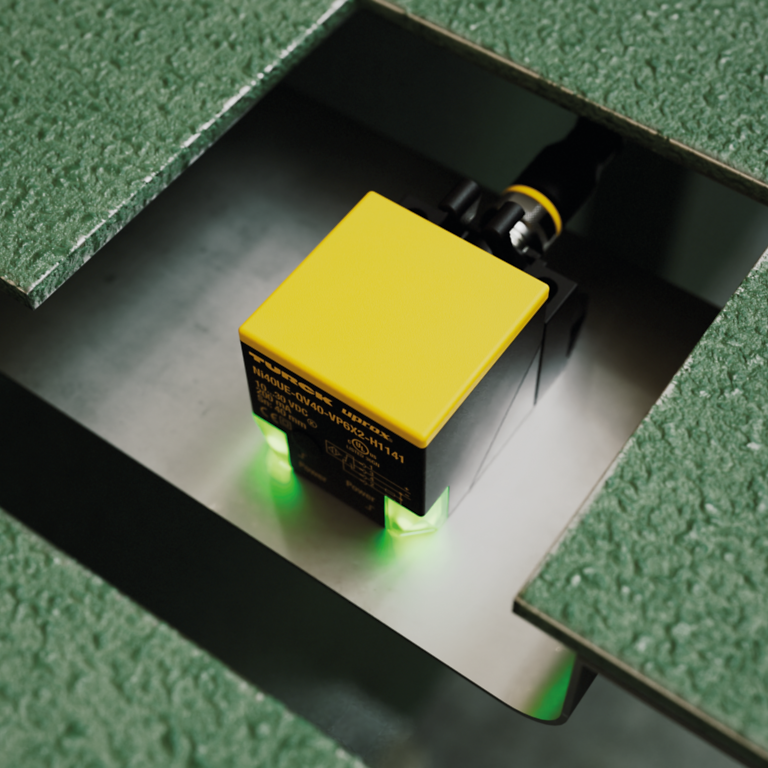

The NI40UE-QV40 inductive factor 1 sensor has a switching distance of 40 mm for precise skid detection even in small spaces. It is mounted in a recess in the skid frame, with the surrounding metal parts providing protection. The sensor has minimal metal-free zones, making it ideal for applications in confined spaces.

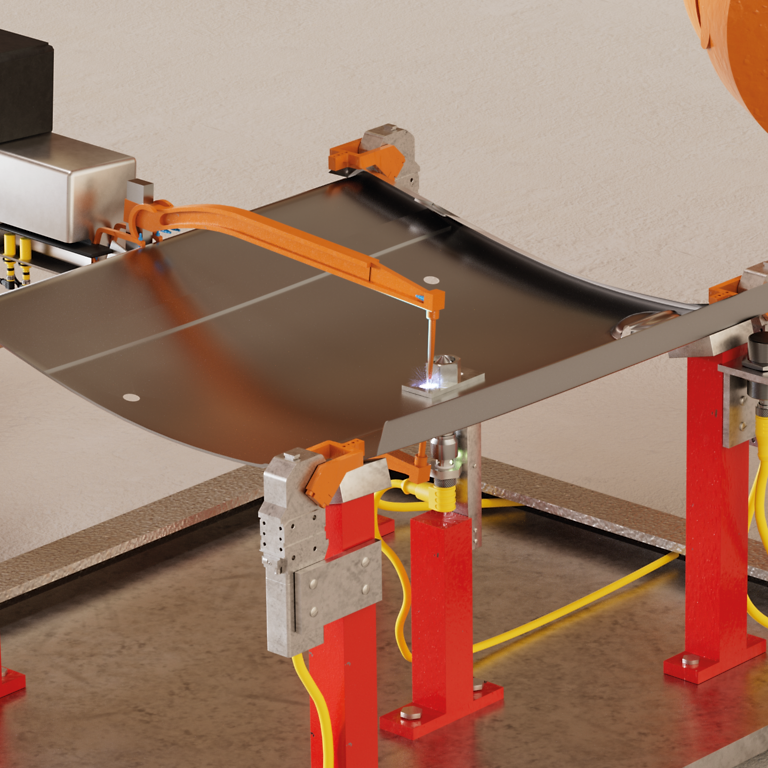

The tool-free adjustment of the active surface in five directions makes installation considerably easier and allows the sensor to be flexibly adapted to any application. Its high magnetic field immunity of up to 300 mT, IP68 protection and temperature resistance from -30 to +85 °C also make it highly resistant to environmental influences, which is ideal for cells with welding robots, and increases system availability for reliable skid detection in production.

"The robust NI40UE sensor is easy to install and provides reliable skid detection in compact spaces."

Sander Makkinga | Director Product Management Position/Proximity Sensors | TURCK GmbH