Complete sensor-to-cloud solution for assembly machine

High product diversity with minimal setup times: Eberhard AG builds a powerful assembly system for M8 and M12 connector sockets

Quick read

As a strong partner in the field of automation, Eberhard AG develops, manufactures, and sells customized automation and assembly systems worldwide. Depending on customer requirements, individual stations are combined individually to form complex systems and then integrated into production lines. For the production of M8 and M12 female connectors for use in TURCK's block I/O modules, Eberhard AG developed an assembly machine and benefited from the use of these very block I/O modules during its construction. In addition, Eberhard AG was impressed by TURCK's pressure sensors and the photoelectric sensor components from Banner Engineering. The assembly system excels with its minimal setup times and high precision.

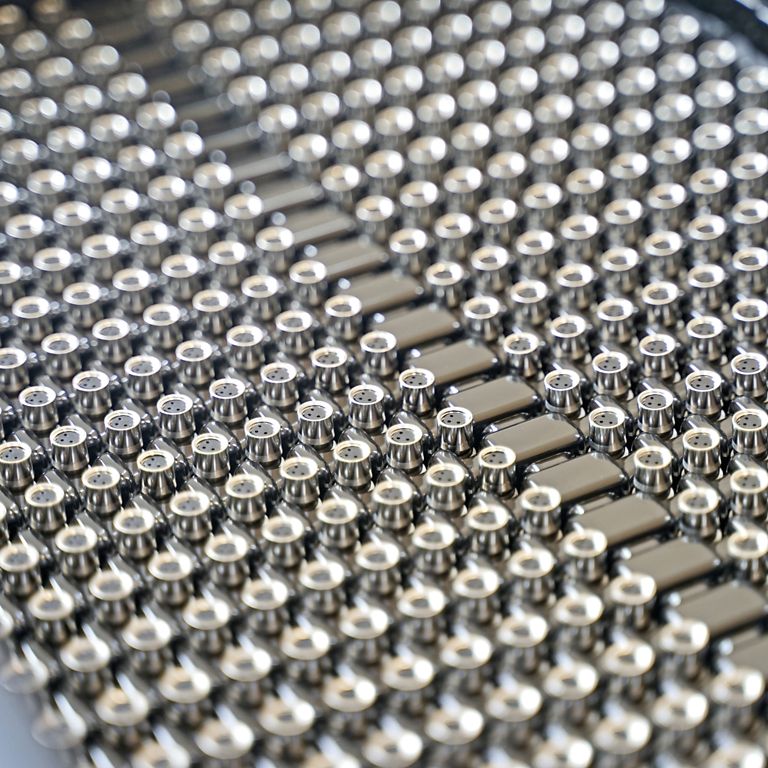

When it comes to wiring industrial systems, machines, and devices under demanding operating conditions, circular connectors are one of the most widely used physical interfaces worldwide. M8 and M12 have become the standard sizes for more compact devices. For the automated assembly of M8 and M12 circular connectors with different codings for use in TBEN block I/O modules, each with or without a protective earth (PE) connection, TURCK was looking for an assembly solution that offered fast throughput times, scalable quantities, and maximum process reliability. The assembly of millions of round connectors places high demands on automated systems. This is especially true when regular changeovers are required depending on the variant. In addition, the machine should not only perform the actual assembly, but also the visual inspection of the assembly and finally the packaging of the round connectors in trays.

Experienced special machine manufacturer

The production planners at TURCK had already had good experiences with special machines from Eberhard AG at various production sites. So the company from Schlierbach in Baden-Württemberg was also awarded this contract. For over 50 years, the company has been supporting electronics manufacturers and automotive suppliers worldwide with modular and powerful solutions for the production of connectors and other electromechanical components. Our core competencies include all standard processes in assembly technology, contact placement and bending, testing and packaging, and product handling in accordance with customer requirements.

"We were particularly impressed by the variety and flexibility of the distributed block I/O modules. TURCK's hybrid TBPN Profinet /Profisafe module in IP67 combines standard and safe inputs/outputs in one device, which can be flexibly parameterized."

Andreas Wißt | Eberhard AG

Automated assembly

The assembly system inserts the metal contacts into the plastic cores of the future sockets and fits the metal socket body over the plastic core like a sleeve – a ground connection is added beforehand. Process control is handled by a Siemens PLC. The remaining automation tasks were mainly solved with TURCK components, including sensors, safety light curtains, block I/O modules, HMI operating devices with direct cloud connection, and connection technology.

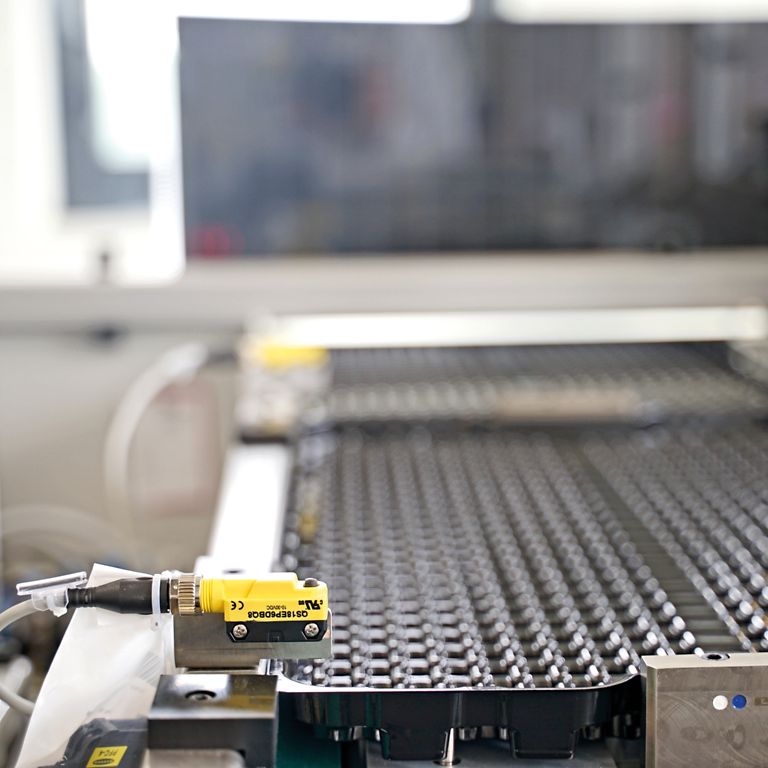

Like the metal bodies, the plastic cores are fed via a spiral conveyor. A QS18 photoelectric sensor detects the tray on which the finished sockets are placed. The opto-sensor from Banner Engineering thus ensures the orderly inflow and outflow of the plastic carriers. In the palletizer, Banner Engineering safety light curtains are used in tunnel mode to protect the system operators from accidentally reaching into the danger zone of the machine. After feeding, a camera system measures the position of the plastic parts based on the guide and the hole geometry. The system reports a degree value to the control system so that the robot can pick up the plastic parts in the correct position or correct their position. Once the actual and target loading positions have been compared, the robot moves the plastic part to the rotary table, where it rotates it into the correct position and inserts it.

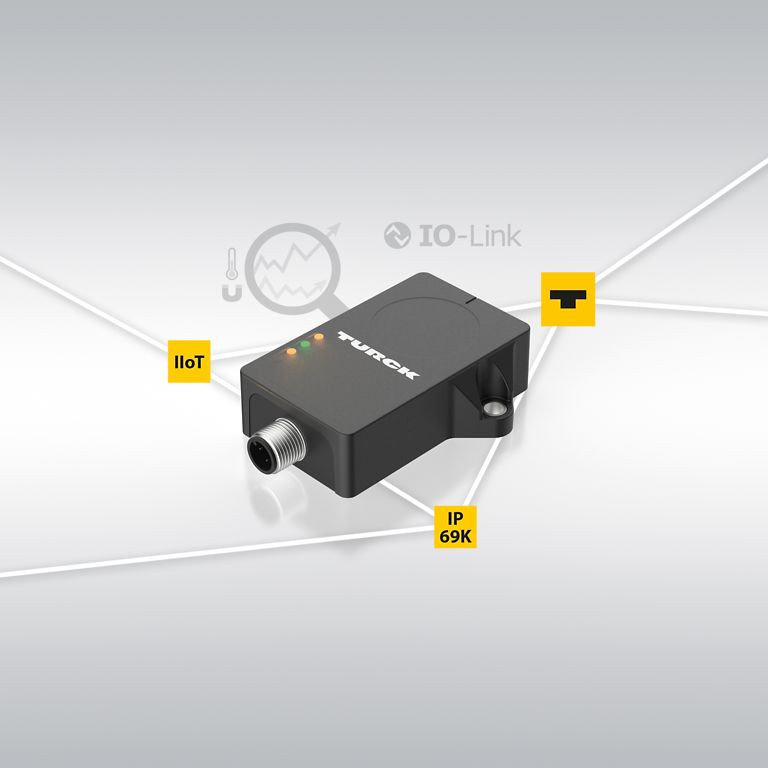

During the placement process, a QM30 sensor attached to the placement head records vibration data, which is visualized via a dashboard and can be used for condition monitoring and predictive maintenance.

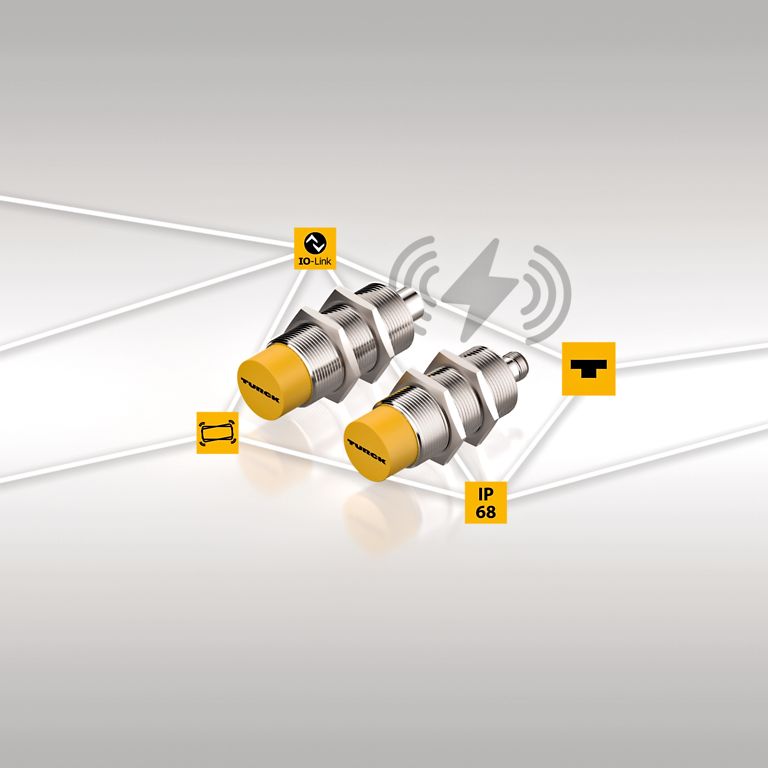

Plug-and-play device replacement with IO-Link

One requirement was to be able to replace sensors on the machine using the plug-and-play principle so that they could be replaced in the event of a defect and used immediately without having to be re-parameterized. This requirement was met with smart IO-Link sensors. Parameter sets from IO-Link devices can be stored in the IO-Link master and applied to any replacement device. Other IO-Link components in the system include valve terminals, including the large main terminal on the loading head, and pressure sensors from TURCK. “The PS+ pressure sensors deliver on their promise of intuitive commissioning and operation,” confirms Andres Wißt, Head of Software Engineering at Eberhard AG. The PS+ sensors monitor pressure changes in the pneumatic system. If the system delivers values that deviate from the norm, the user is alerted.

Flexible I/O and safety modules

Eberhard relied on TURCK's TBEN I/O module portfolio to connect the IO-Link signals as well as the classic digital input and output signals. “We were particularly impressed by the diversity and flexibility of the decentralized block I/O modules,” says Andreas Wißt. “TURCK's hybrid TBPN Profinet/Profisafe module in IP67 combines standard and safe inputs/outputs in one device, which can be flexibly parameterized. I was very surprised by what this device can do.”

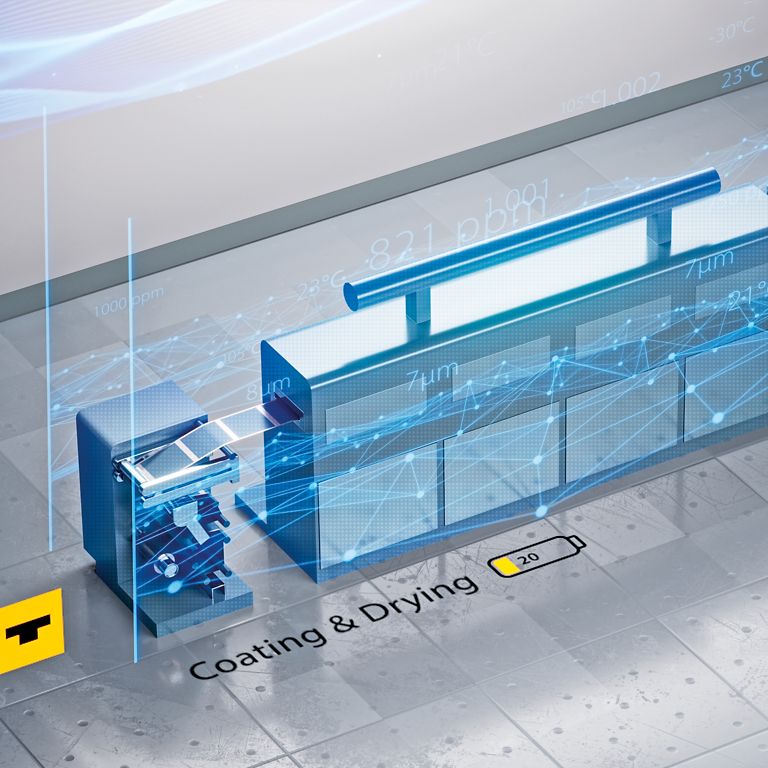

An HMI from the TX700 series serves as a fixed panel for visualization and is also used as a cloud gateway. “A big advantage,” says Wißt. “One of the requirements was to provide data for the cloud. This was only possible with the TURCK HMI – and without any problems.” The HMI accesses the control data via OPC UA. Relevant data can thus be uploaded to the cloud, where key figures such as parts produced, fault messages, or machine downtimes are derived. These are visualized on a central monitor in the factory.

Further applications are being examined

Based on the positive experience, the project participants at Eberhard AG are examining additional scenarios for the use of TURCK components in other projects. “This applies to the sensors and, above all, the TBEN modules as a whole,” says Wißt. “This allows us to benefit from their diversity and flexibility, especially with the hybrid safety module.”

The assembly system is now running successfully at the production site in Lublin, Poland. Following the positive experience with the machine and in anticipation of continued high demand for M8 and M12 sockets, another machine has already been ordered. “The cooperation with the project management and those responsible was excellent—also on a personal level. Very communicative and relaxed,” says Wißt. “This is especially true considering that it was the first machine of its kind and everyone involved was able to learn something new. I look forward to further projects.”

Customer | www.eberhard-ag.com

Ralf Moder is a sales specialist at TURCK