Pick-by-light solution simplifies assembly processes

How the digitization of picking, assembly and logistics processes reduces employee workload and increases efficiency

Quick read

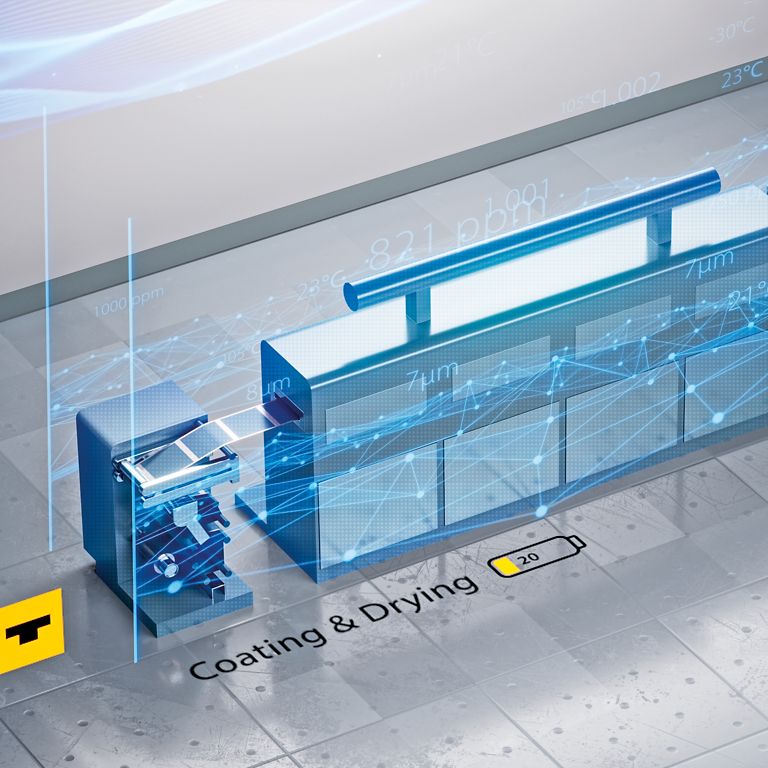

Whether in assembly, order picking or logistics, errors occur repeatedly—and they cost time and money. To achieve the lowest possible error rate, processes must be optimized and available resources used as efficiently as possible. With its "Smart Light Touch" pick- by -light solution, CSAE GmbH, a system integrator based in Wolfsburg, supports this approach. The solution is a modular, automated, end-to-end system for visual operator assistance based on TURCK components. The system reliably guides employees through assembly and picking processes using light signals.

Wherever people work, mistakes can occur. In production and assembly processes, even the most conscientious and experienced employees occasionally make errors. Components may be picked incorrectly from a bin, either selecting the wrong part or the wrong quantity, or they may be assembled in the wrong sequence. The consequences can include rework, recall campaigns or even damage to the company's reputation. For this reason, error-free operation is of critical importance for high-quality products. To achieve maximum throughput, assembly must also be performed as quickly as possible. The challenge, therefore, is to combine fast assembly with the highest possible level of quality.

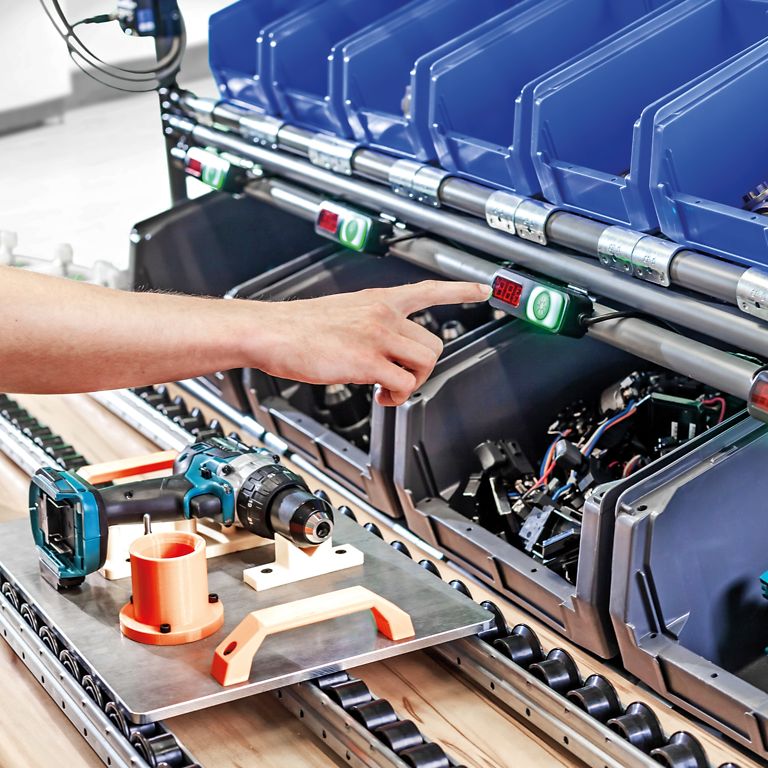

To increase efficiency and accuracy in assembly, it is essential that employees can quickly and easily identify the next parts bin. A customer-specific, light-guided operator assistance system clearly indicates which bin the employee needs to pick the next part from. In addition, the system records the pick and immediately highlights the subsequent bin.

Because custom solutions are typically very expensive due to high development costs, system integrator CSAE has developed a pick-to-light software platform based on experience, ideas and customer requirements gathered over the past 25 years. Its functional scope covers the majority of conventional requirements as well as the needs of new customers. This control software forms the basis for customer applications and is significantly more cost-effective than programming a tailored solution. Only customer-specific interface requirements are addressed on a project-by-project basis. "This is—and will remain—customization effort on our side," explains Oliver Gundlach, Team Lead Automation Engineering at CSAE. "It is not the customer who has to adapt to our solution, but the other way around. Depending on the customer's system, we adapt our solution so that it works within their application."

"The TBEN-L-PLC is robust and suitable for direct use in the production environment. It is an ultra-compact device that offers a wide range of capabilities—particularly when it comes to interface diversity."

Oliver Gundlach | Teamleiter Automatisierungstechnik | CSAE

Modular and easy to expand

Within the modular "Smart Light Touch" end-to-end system, the control software is the central component. Another key element is the shelving; however, the system is fundamentally independent of the shelving type and can be adapted both to new shelving systems and to existing customer shelving. Modbus/TCP-capable components from TURCK complete CSAE's pick-by-light solution. These primarily include the PTL110 pick-to-light devices with a 7-segment display, illuminated pushbutton and acknowledgment sensor; the compact K30 Pro LED indicator with illuminated pushbutton; and the WLS LED task light without a pushbutton element.

Depending on customer requirements, the system can be expanded with additional visual components from the TURCK portfolio. The prerequisite is that these devices support Modbus/TCP, as this protocol enables fast, flexible and efficient communication in industrial networks. For lighting components, CSAE's specialists rely on Modbus/TCP because the protocol offers a high degree of flexibility and provides secure, proven communication. To further increase safety and, for example, display assembly steps, a panel PC can be integrated directly on the shelving. This gives employees clear, detailed overviews of the work process.

TBEN-L-PLC overcomes the limitations of PC-based control systems

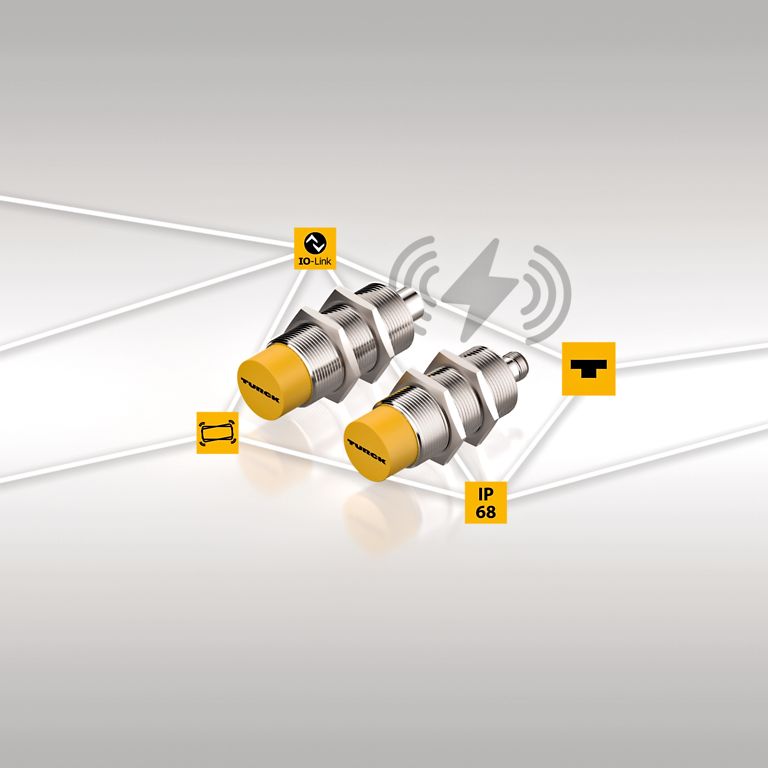

For the Smart Light Touch control software, CSAE was looking for a PLC that provides sufficient capacity for SAP connectivity and additional interface connections, as well as visualization capabilities. The choice fell on TURCK's robust compact controller, the TBEN-L-PLC. Designed for industrial use, the IP67-rated controller enables control-cabinet-free, modular machine concepts for Industry 4.0 and IIoT applications when used as a block I/O module. It not only features a CODESYS-based PLC onboard, but also supports direct cloud connectivity and, thanks to its multiprotocol technology, can communicate simultaneously via multiple Ethernet protocols.

By using the TURCK controller, the limitations of PC-based control systems can be overcome from the outset—such as difficulties in retroactively implementing system changes and the often lacking long-term support, which in PC-based systems depends on the respective Windows version. "For us, it was important to be able to connect to the network. The TBEN-L-PLC is robust and suitable for direct use in the production environment—an ultra-compact device that offers extensive functionality, particularly in terms of interface diversity," says Oliver Gundlach. "Another key prerequisite for implementing customer-specific interface requirements is the straightforward cooperation between TURCK support and our programmers. Technical modifications, such as firmware adjustments, are also implemented at short notice."

Simple installation and commissioning

The simple installation of the CSAE system is unique across the market: from assembling the shelving to commissioning. "You don't even need a screwdriver for installation," says Gundlach. "And commissioning is carried out easily via a website—nothing more. It's a unique selling point that is truly unmatched."

The system is designed so that any customer can easily plug together the Smart Light Touch hardware components directly on the shelving—without any technical background. The individual components can be mounted to the shelving using click-in and screw-fastening mechanisms. No IT specialists are required for commissioning, allowing customers to carry it out themselves. The CSAE customer portal provides continuous support through operating manuals, video tutorials and a support contact. "We also think about small and medium-sized enterprises that cannot afford to hire programmers," says Sales Director Sarah Wedekind. "We want to specifically address these companies as well and support them in digitizing their logistics. That's why we offer an intuitive and easy-to-use system that customers can configure independently."

Personalization with individual color settings

Using a higher-level system or a transponder, Smart Light Touch is able to identify at any time which employee is working and at what time. After logging in to the system, employees can individually adjust the system's colors to suit their personal preferences or needs. For example, an employee with red–green color vision deficiency can select alternative colors instead of red and green, enabling error-free operation. Company colors or simply an employee's preferred colors can also be configured. In addition, colors can be assigned so that they immediately indicate which tool should be used with the currently selected part. This means that employee can personalize their workstation according to their individual preferences.

High employee satisfaction

Smart Light Touch supports assembly operators and significantly reduces their error rate, thereby minimizing rework and recall actions. A major advantage of the light-guided operator assistance at the shelving, combined with visualization of the work steps, is a substantially higher assembly speed and the resulting increase in productivity. There is no longer any time lost thinking about the next work step or which tool is required for the part that has just been picked.

New employees or temporary replacements can also work independently after a short onboarding period and reach full performance quickly. Because operation of the pick-by-light system is based on light signals, it can also make it possible to employ workers who may previously have been excluded from the workforce—for example, due to limited language skills or minor impairments.

Summary

The simple installation of CSAE's automated, modular Smart Light Touch pick-by-light solution is unique across the market. Customers have the option to assemble and commission the system themselves—without programmers or any technical background. A direct cost advantage for customers lies in the proven control software, which was developed based on customer requirements gathered over recent decades and covers a large portion of market needs. Customer-specific interface requirements are addressed individually and are typically implemented very quickly thanks to the technical capabilities of TURCK's TBEN-L-PLC compact controller and the close collaboration between TURCK and CSAE experts.

Customer | www.csae.de

Christian Philipkowski is head of the Application and Service Center at TURCK