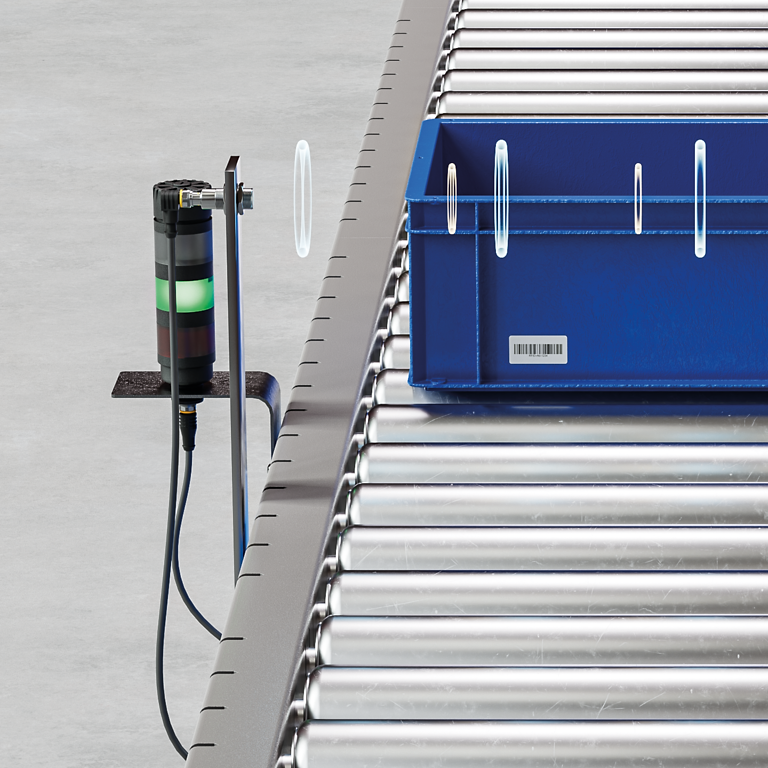

Detection of reusable containers

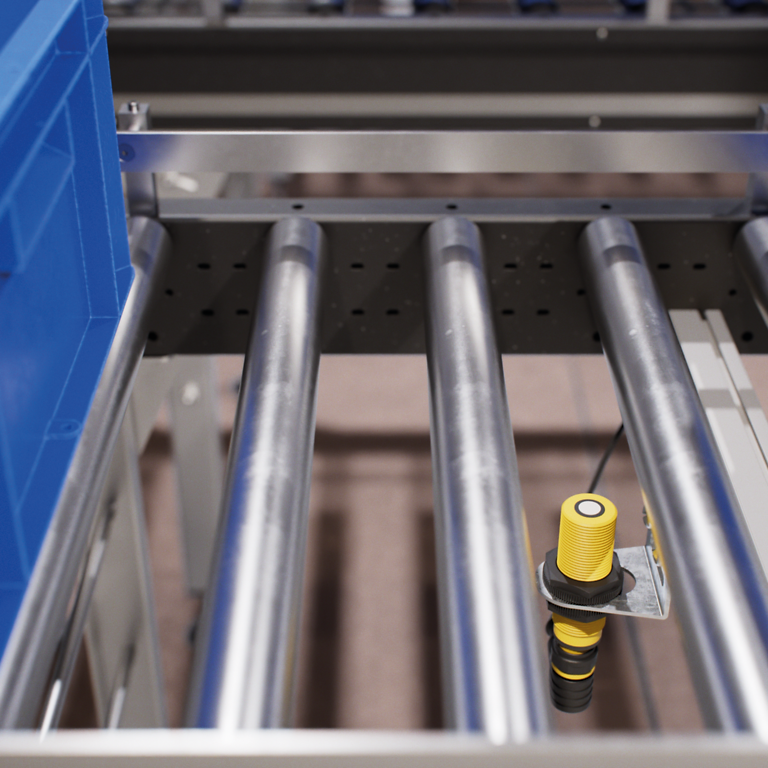

RU50 ultrasonic sensors reliably and efficiently detect transport boxes on roller conveyors

Benefits

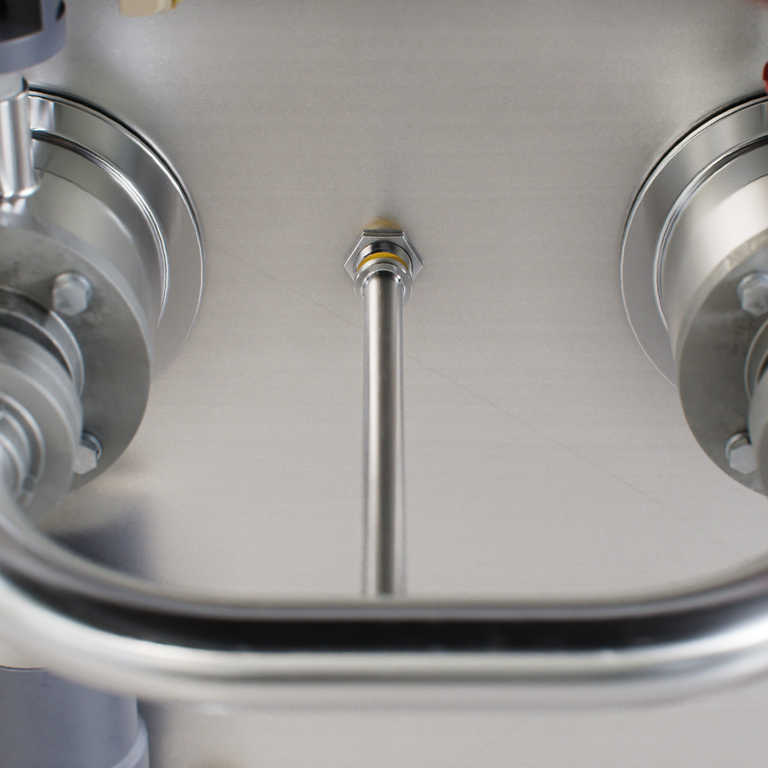

Minimal contamination thanks to the smooth transducer front

A translucent end cap enables quick diagnostics from almost any viewing angle

Energy-efficient conveyor technology, as the drive runs only when a container is present

Challenge

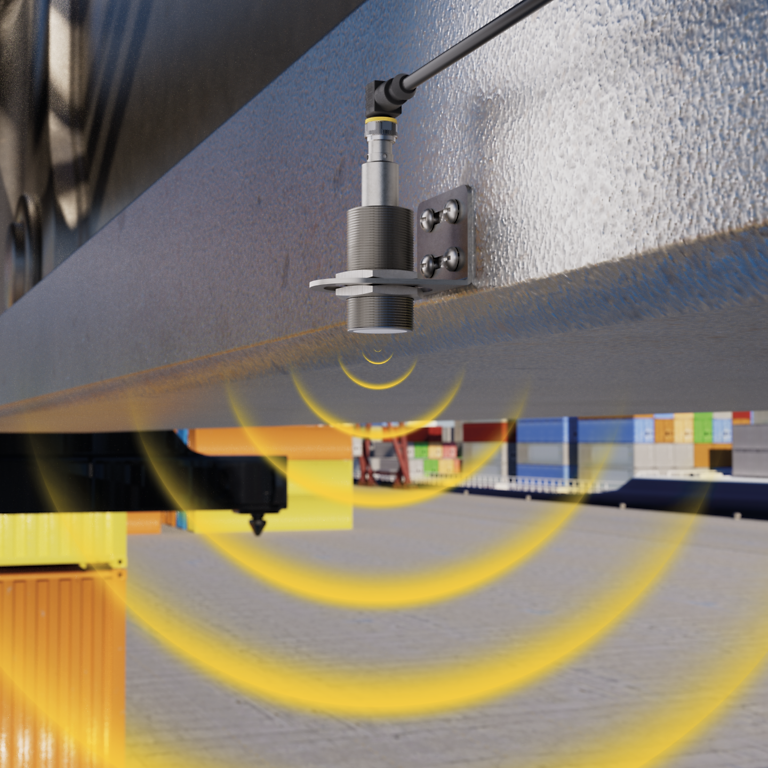

Sensors on roller conveyors must precisely detect containers to efficiently control material flow in production facilities. Optical sensors reach their limits in poor lighting conditions, with contamination or on reflective surfaces. A reliable object detection solution is essential to ensure smooth operation, save energy and reduce wear.

Solution

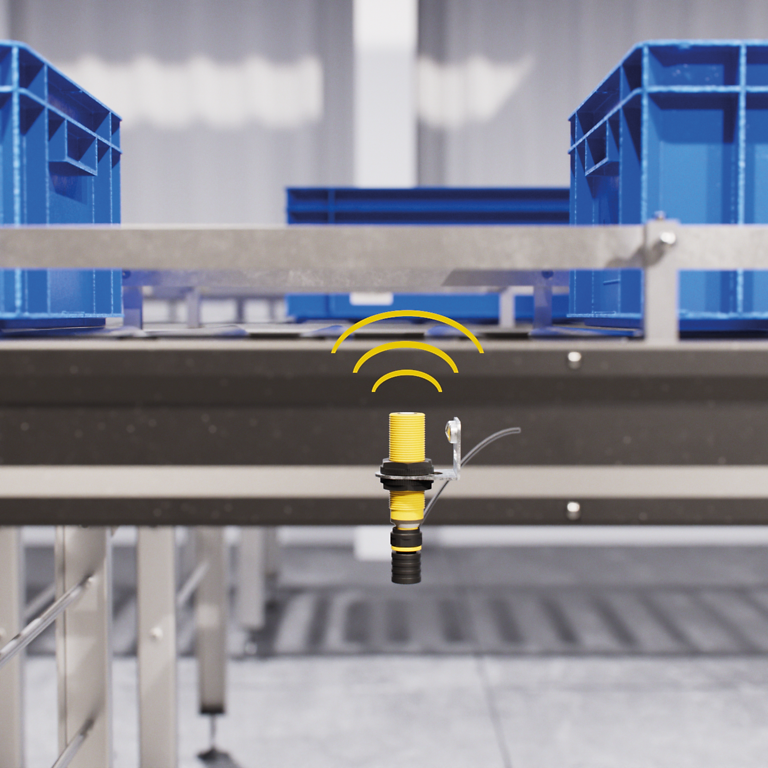

TURCK's ultrasonic sensors in the RU50 ECO product series detect transport containers regardless of color, material, transparency or lighting conditions. They operate reliably as a reflective barrier by using an opposing guide plate as a reflector. If the container leaves the detection area, the sensor immediately detects this and reports the change to the control system.

By connecting directly to the drive, roller conveyors can operate more energy efficiently: The drive runs only when a container is actually being transported. This reduces energy consumption and minimizes wear. The sensor's translucent end cap allows quick identification of the switching state from almost any viewing angle, which is an advantage during maintenance and commissioning.

The ECO product series has been specifically optimized for cost-sensitive, high-volume applications. Thanks to their compact design and easy integration, the sensors are ideally suited for use in modern conveyor systems.

"Our ECO product series is an efficient, cost-effective solution for container detection that brings together material flow, energy savings and process reliability in an optimal way." "

Jannik Suchowitzki | Product Manager Distance Sensors | TURCK GmbH