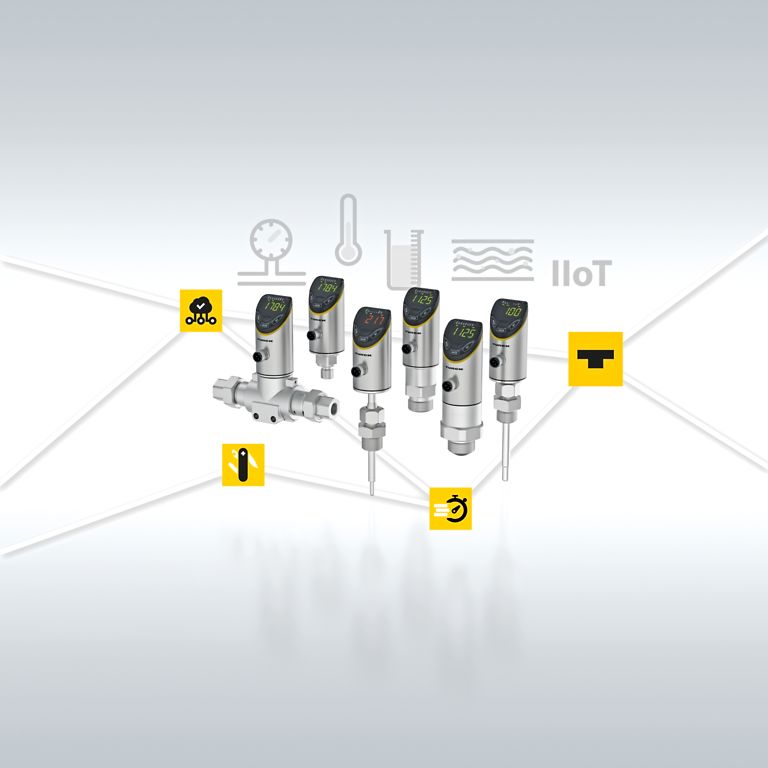

Generation Plus: Fluid sensors with added value

Flexible installation options, intuitive operation, maximum robustness and a uniform look & feel – This is what TURCK's Fluid+ platform promises across all sensor variants

Quick read

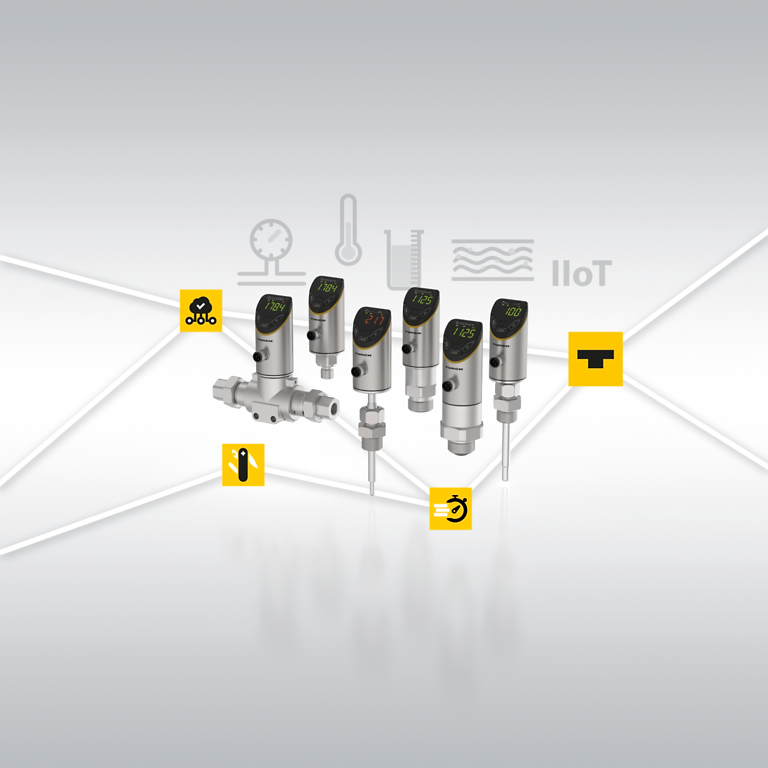

With a design that has received multiple awards, a unique user interface, and a consistent look and feel across platforms, the IO-Link-enabled sensors in the Fluid+ family set high standards and combine innovation, functionality, convenience and usability in an intelligent system – for recording pressure, temperature, flow or fill level.

Precise pressure, flow and temperature measurement as well as continuous fill level measurement and limit value detection require a wide range of tailor-made solutions, which involves increasingly complex fluid sensor portfolios. Logistical processes are becoming confusing, warehousing is time-consuming and leads to longer delivery times. At the same time, ever shorter development cycles pose additional challenges for development: speed, flexibility, scalability and efficiency are becoming more critical success factors than ever before. This is exactly where TURCK's modular Fluid+ family comes in.

Consolidation through platform strategy

The Fluid+ architecture divides the complex product family into its individual elements, which are assigned to specific modules. The interaction of the individual modules is limited to standardized interfaces so that the modules can be developed independently of each other. This freely configurable concept of the Fluid+ platform promotes a wide variety of devices, simplified warehouse management and shorter delivery times, meaning that sensors in particular demand are available within a few days.

Innovative design concept

TURCK's Fluid+ platform is based on the simple strategy that the same product is the same and looks the same for the user throughout the family. This means that all Fluid+ sensors have the same appearance and familiar handling, regardless of the application.

The characteristic feature of the compact sensors is their sensor head, which consists of a stainless steel housing and a one-piece, translucent front cap. Due to the reduced sealing surfaces, neither moisture nor dust enter the inside of the devices, as the sensors no longer have mechanical operating elements that need to be sealed. In addition, UV and salt spray-resistant materials ensure maximum protection in the outdoor area. As on a smartphone, users navigate using wear-free, capacitive touch pads. This makes it much easier to expand and maintain systems, as employees only need to be trained on a single operating concept. The neutral M18 x 1 union nut allows various process connections to be adapted to the respective application. In this way, the devices of the Fluid+ family are varied and can be combined, but at the same time share essential properties. Both the uniform look and feel and the input concept are unique in the industry.

Multiple awards

In 2019, the PS+ pressure sensor, the first sensor in the Fluid+ family, was awarded the iF Design Award in the "Industry/Tools" category. The prize, which has been awarded annually since 1954, is a recognition of special achievements in product design. The jury was particularly impressed by the platform-spanning, innovative operating concept of the sensor family.

However, TURCK's Fluid+ sensors were not only able to convince specialist juries. There was also a lot of support from interested users. The fluid sensors family therefore also received the Automation Award of the trade magazine elektro AUTOMATION in 2019. The majority of visitors to the SPS – Smart Sensor Solutions trade fair in Nuremberg chose the product series as number one in the standard components & sensor technology sector. The interaction of a uniform technology concept and functional design impressed the specialist audience.

The readers of the trade magazine Computer&Automation voted TURCK's smart FS+ flow sensor second in the Sensor Technology & Measurement Technology category as "Product of the Year 2021." More than 6100 readers took part in the online survey and selected their favorites from over 500 products in a total of twelve categories.

Simplified integration and commissioning

Important requirements for the development of the Fluid+ family were smooth installation and simplified commissioning and operation. The user should be able to quickly find their way around the menu structure. In addition to a consistent user interface, the Fluid+ family offers particularly flexible mounting options, as the sensor head can be rotated 340 degrees freely and the display can be reversed for an overhead installation. The sensors automatically detect whether the controller or the fieldbus module expects PNP or NPN signals on the input side. If analog output signals are evaluated, the same applies to current or voltage. Plug-and-play becomes a lived practice.

The display of the Fluid+ sensors is larger and brighter than other devices, which enables easy visibility from any position when mounted accordingly. The touch-sensitive keypads of the innovative smartphone-like operating unit can also be operated with different glove types, without the need for force or cumbersome aids. A locking mechanism initially prevents possible operating errors. Operation is only enabled after swiping the display.

User-friendly navigation guides the user intuitively through the plain text menu, whose structure follows either the TURCK or the VDMA standard. Relevant settings can be made easily and conveniently by touching the respective operator panel. Advanced functions such as setting up password protection or changing the color of the display as a prompt for action when defined switching points are exceeded can also be configured in this way.

High system availability

When it comes to system availability, reliability is the key word. The capacitive touch pads also come into play here. The stainless steel housing, in combination with the one-piece cover, is an extremely robust design. The absence of mechanical operating elements and the resulting reduced number of sealing surfaces provides maximum protection against the ingress of moisture and dust into the device interior and ensures a high degree of wear-free operation. The sealing concept enables the IP66, IP67 and IP69K degrees of protection. Very good shock and vibration properties as well as a high pressure resistance ensure reliable operation and thus high system availability, even in the harshest environments.

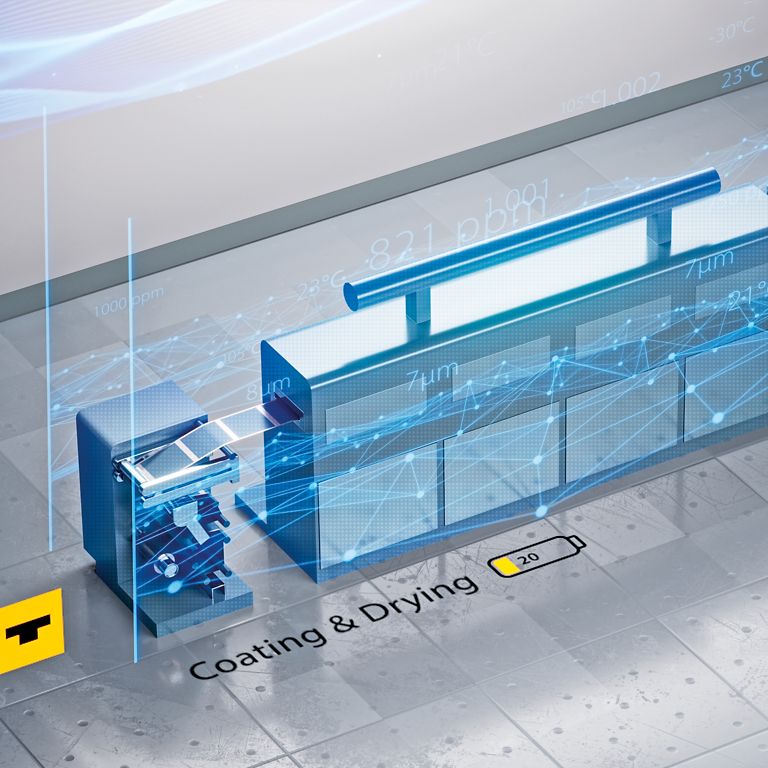

Communication concept for Industry 4.0

Consistency and transparency in the acquisition, transmission and processing of sensor data are key requirements of Industry 4.0. The devices in the Fluid+ family therefore support open standards such as IO-Link 1.1, via which they communicate bidirectionally with the control system. In addition to process values, the IO-Link interface provides the user with numerous types of condition monitoring data for smart IIoT applications. The sensors not only transmit digital process values, but also receive parameters such as switching points. To prevent machine failures, diagnostic data can be read and evaluated via IO-Link. This allows users to detect irregularities at an early stage and prevent possible damage.

Devices in the Fluid+ family offer various IO-Link process data profiles, enabling the sensor to be easily integrated into existing system landscapes by replacing existing devices on a 1:1 basis, even from third-party manufacturers. This eliminates the need for complex adjustments to the control system environment.

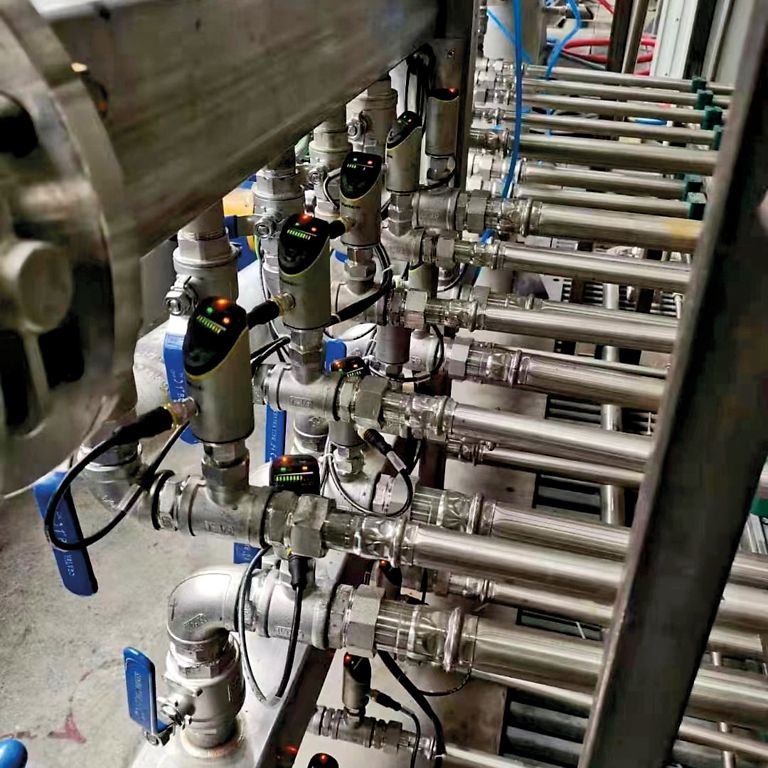

PS+ pressure sensors – maximum robustness

In 2019, the robust and user-friendly PS+ pressure sensors were the first products in the Fluid+ family. The pressure sensors enable reliable and reproducible measurement of process pressures in industrial applications. With a wide range of different pressure ranges and process connections, the system offers a versatile range of options that can be used for most applications. Typical applications are hydraulic applications, cooling circuits and lubricant applications.

PS+ pressure sensors are designed for pressure ranges up to 600 bar and are available with both proven ceramic measuring cells (PS310) and metal measuring cells (PS510). The measuring cells have a burst pressure that is at least four times the maximum nominal pressure. The minimum/maximum pressure accumulator forms a digital "drag indicator," which makes it possible to analyze processes even better. The pressure sensors of the PS+ series ensure hermetic tightness even in the event of an overload.

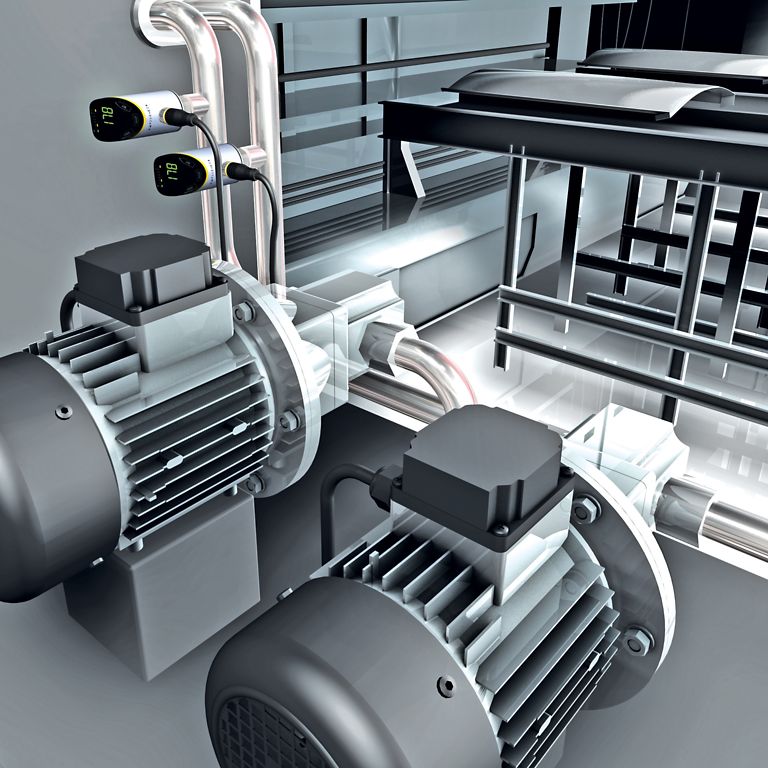

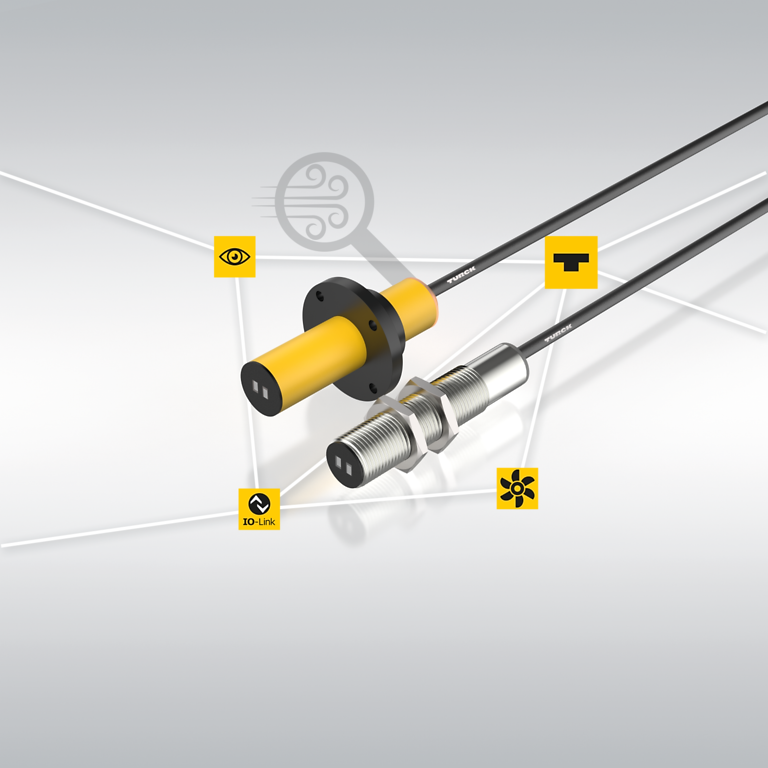

FS+ flow sensors – one sensor, two queries

The compact flow sensors of the FS+ series can be integrated quickly and conveniently in machines or plants. They monitor liquid media according to the calorimetric principle and therefore offer the possibility of measuring the medium temperature permanently in addition to the flow. This means that a single sensor can perform two tasks at once. Typical applications are cooling circuits in welding applications, dry running protection of pumps and cleaning processes. Reliable monitoring of flow and temperature and end-to-end communication via IO-Link ensure plant operation and reduce downtimes. With their wide range of mounting options and intuitive commissioning, the FS+ flow sensors also facilitate engineering.

In the FS100 product series, users can choose between devices with two output functions: either analog (4...20 mA) or with automatic PNP/NPN detection and communication via IO-Link 1.1. The switching behavior can be set between " Normally Open" (NO) and " Normally closed " (NC). All-round LED displays signal the status of the outputs, while a two-color LED bar on the user interface displays flow or temperature values as required.

The quick teach-in function offers significant advantages in addition to simplified mounting and automatic detection of PNP/NPN signals. It allows a switching point to be set directly on the device in just a few seconds. Delta flow monitoring ensures that the teach-in point is learned at the right time.

TS+ temperature sensors – maximum degrees of freedom

The sensors in the TS+ series guarantee reliable and reproducible measurement of process temperatures in industrial applications. The large number of different measuring ranges and process connections offers a wide range of variants that can be used to implement most applications without any problems. The TS+ sensors are available both as compact devices with an integrated temperature sensor (TS700) and as evaluation and display units (TS720) for the connection of resistance thermometers or thermocouples. The devices support and detect almost all industry-typical temperature sensors – such as resistance thermometers or thermocouples – fully automatically.

To simplify commissioning, the TS+ devices also offer automatic detection of the output type (PNP/NPN or current/voltage). The TS720 signal processors also detect the type of temperature sensor connected (TC or Pt-RTD), eliminating a common source of error. If the TS+ is to be integrated into existing plant systems or replace existing sensors, the selection of different IO-Link process data profiles enables rapid adaptation without complex changes in the control system.

Typical areas of application for TS+ sensors are in machine and plant engineering as well as in the process industry. Compact devices of the TS700 type work in a measuring range from -50 to +150 °C. Depending on the connected temperature sensor, evaluation and display units of the TS720 type can even measure values between -200 and 1800 °C.

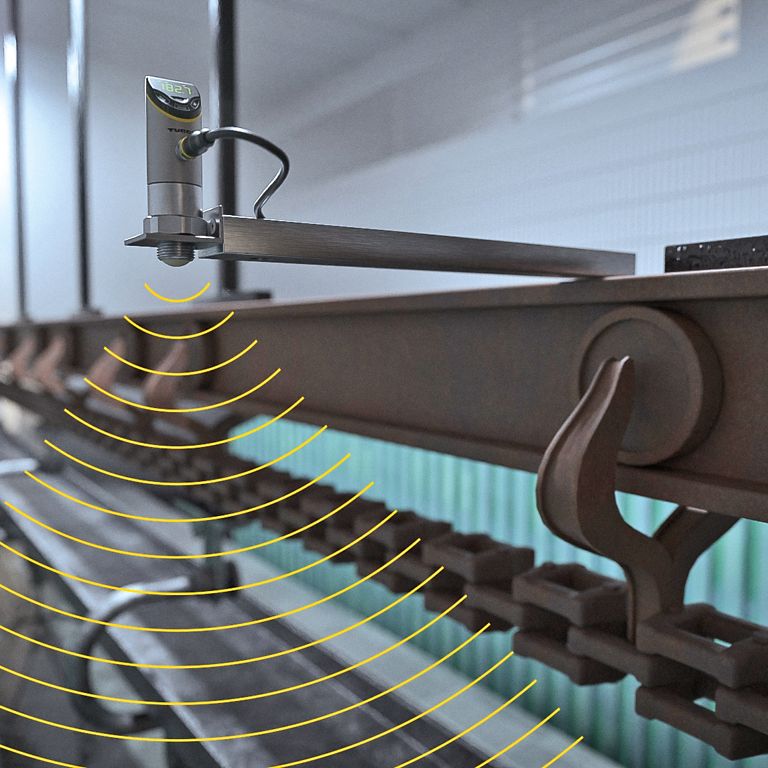

LS+ fill level sensors – efficient problem solvers

TURCK offers two different sensor technologies in the LS+ series to enable users to use the optimum measuring principle for different application scenarios: the LRS fill level sensors with radar technology for larger detection ranges and the LUS ultrasonic fill level sensors for smaller and medium-sized containers.

The IO-Link-capable radar sensors in the LRS series were developed for fill level measurement in tanks and silos in the range of 0.35 to 10 m. They solve problems where other sensor technologies reach their limits. The devices with degree of protection IP67 and IP69K are particularly recommended for fill level applications in factory automation in which optical or ultrasonic sensors are unsuitable due to their limited range or interference factors such as dust, wind or light incidence. The free-radiating LRS radar sensors also offer extensive analysis functions that were previously reserved for the high-end radar sensors most commonly used in the process industry.

The control unit of the LRS series with capacitive buttons and translucent front cap follows the concept of the Fluid+ family and enables the output of distance, fill level and volume values. LRS sensors are available with either two switching outputs or with one switching output and one analog output. Thanks to their additional IO-Link interface and intelligent, decentralized signal preprocessing, all variants also provide numerous types of additional information for processing in condition monitoring applications in the IIoT. In addition to the signal strength, this information includes temperature values, operating hours or switching cycles.

Users of the IO-Link master from TURCK can call up the radar monitor without additional software via the IODD configuration tool. The browser-based configuration tool displays the measurement curve of the sensor graphically and provides clear text access to all relevant parameters. For example, the interference signal of a stirrer or grid can be easily suppressed or the sensor can be perfectly aligned using real-time feedback to maximize the reliability of fill level detection. Typical areas of application for LRS sensors are in machine and plant engineering, in the automotive industry, as well as in the food and pharmaceutical industries.

The LUS ultrasonic fill level sensors are ideally suited for cost-effective fill level measurement in small and medium-sized tanks and can be operated at pressures of 0.5 to 5 bar at the process connection. They are available with standard process connections G ¾ and NPT ¾ for a range of 40 or 130 cm, either with two switching outputs or with one switching output and one analog output. Thanks to their IO-Link interface and decentralized signal preprocessing, all variants are also suitable as smart data suppliers for the IIoT. IO-Link can also be used to parameterize the sensors with existing container geometry data, so that it outputs absolute or percentage distance, fill level or volume values directly.

Due to the high degree of protection IP67 and IP69K, the devices can be used reliably even under adverse conditions. The continuous evaluation of the signal strength and the reset and thus protected transducer also ensure increased plant availability. In the event of overfilling, an air cushion prevents the medium from coming into contact with the transducer. The classic areas of application of the LRS sensors are in machine and plant engineering, the automotive industry and the food and pharmaceutical industries.

Summary

The modular and freely configurable mechanical concept of TURCK's Fluid+ family allows for a wide range of variants, compatibility and shorter delivery times, meaning that many sensor variants are available within a few days. The modular design gives all sensors in the Fluid+ family a uniform appearance and comparable handling. This makes it easier for users to expand and maintain their systems, as employees only need to be trained on a single operating concept. Flexible mounting options, intelligent system integration and the innovative control unit with smartphone feel guarantee fast and simple device commissioning. To ensure plant availability, IO-Link-enabled devices provide the user with a wealth of diagnostic data in addition to process values for smart IIoT applications. The sealing concepts and the materials used make TURCK's Fluid+ family extremely resistant to external influences.

All in all, users benefit from an "award-winning" product family that combines functionality, convenience, ease of use and innovation in a smart design.

Thorsten Evers is Business Development Manager for fluid sensors at TURCK