Decentralized control of water treatment plant

In a Belgian nature reserve, a sustainable pumping solution protects the fish stock by means of gentle conveying technology, which is monitored and controlled by TURCK IO-Link solutions, including the ARGEE Field Logic Controller.

Quick read

To protect the fish stocks in the De Blankaart nature reserve, Van Hooste BVBA, a specialist in mechanization and water management solutions, developed a pump with precise control and a slow rotation mechanism that allows a safe passage for fish. The operating parameters are recorded and processed using an IO-Link solution from Turck Multiprox. The TBEN-L5-8IOL I/O block modules and the ARGEE programming platform monitor all sensor data in real time and ensure flexible adaptation.

As a partner for high-quality solutions in mechanization, water management and metal processing, the family-run Van Hooste BVBA, based in Steken, Belgium, has been firmly established for over 40 years. The specialist for water engineering systems offers a wide range of services, from detailed project planning and production to maintenance and development of custom-made products.

The regulation of water levels in nature conservation areas is a complex task, often involving significant risks to fish stocks. The European eel is particularly affected, with its population in sharp decline since the 1960s. Conventional pumping stations cause high loss rates due to their rotating pump blades – fish are often injured or killed. Van Hooste has therefore been commissioned by the Flemish Environment Agency Vlaamse Milieumaatschappij (VMM) to develop a gentle pump solution for the De Blankaart nature reserve in Diksmuide. The aim was to create a fish-friendly pump that ensures the conservation of fish stocks and at the same time effectively regulates the water level.

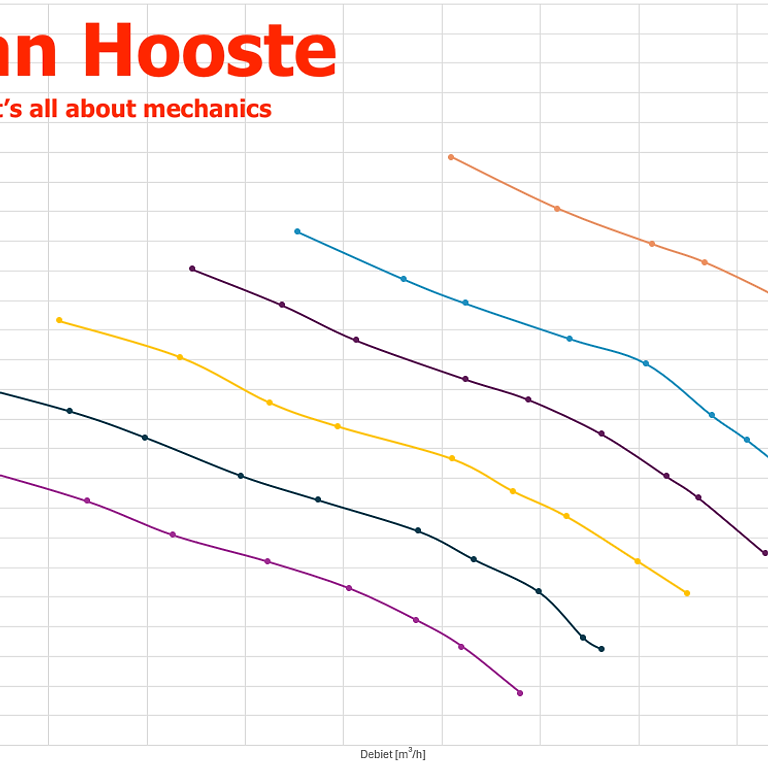

The challenge was to ensure that all relevant measured variables such as pressure, torque, speed and flow rate were accurately recorded in order to create a comprehensive pump characteristic curve. This characteristic curve forms the basis for optimum pump control. Brecht Van Damme, project engineer at Van Hooste, opted for an IO-Link solution from TURCK. The measured values are recorded in real time by pressure transmitters and encoders and processed in the IO-Link I/O module. Real-time monitoring and automated data evaluation enable the pump's operating performance to be continuously monitored and ensure that it operates reliably even under changed environmental conditions. The characteristic curve was successfully validated in several test runs and served as a central basis for the forthcoming implementation of the Factory Acceptance Test (FAT), which prepares the final acceptance by the Flemish Environmental Authority (VMM).

"The great added value of Turck Multiprox was the intensive cooperation and the complete takeover of the electrical part. They took care of the selection of suitable components as well as their programming. Together, we have achieved the goals we were aiming for without any problems."

Brecht Van Damme | Projektingenieur | Van Hooste

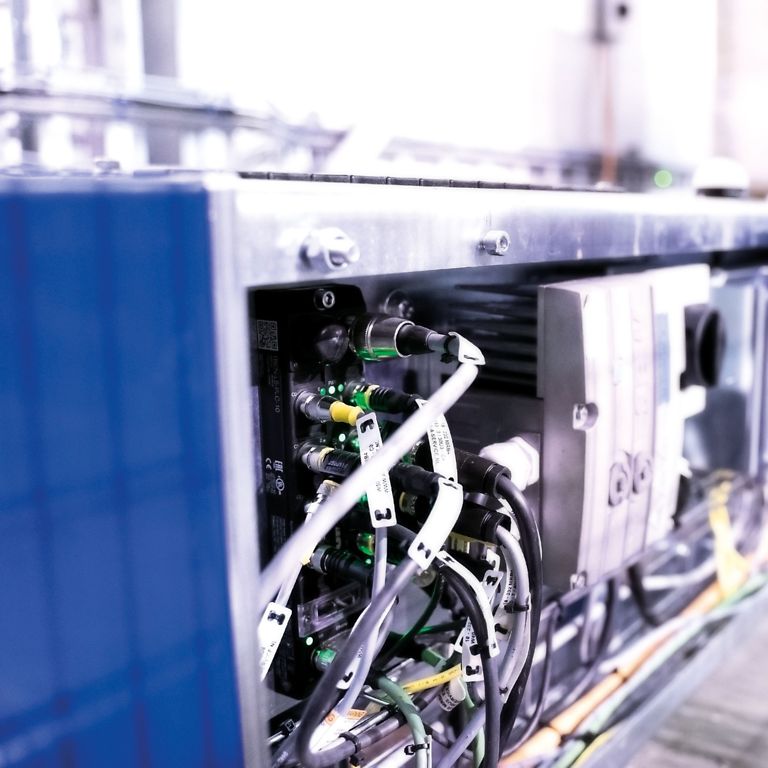

Recording of operating parameters with TURCK sensor technology

Van Hooste uses various sensors from TURCK: an IO-Link pressure transmitter from the PT series, whose measured values are then adjusted to the pump's flow rate. Temperature sensors of the TS700 series monitor the operating temperature of the pump to prevent overheating. In addition, an encoder acts as a speed sensor to ensure that the pump always operates within the specified speed range to ensure that the fish pass gently.

In addition to TURCK sensors, sensors from other manufacturers have also been integrated into the system. The S15C converters from Turck's partner Banner Engineering are used to ensure that their analog output signals (current and voltage signals) can also be integrated into the IO-Link communication system. These converters convert the analog signals into standardized IO-Link data so that they can be processed by the TURCK I/O modules.

Data processing with ARGEE FLC

The programmable I/O module TBEN-L5-8IOL processes the data with its integrated ARGEE control function. The measured parameters can be evaluated in real time using the ARGEE Field Logic Controller. The characteristic curve is automatically documented in an Excel file. This is essential for the performance of the Factory Acceptance Test (FAT), as Van Hooste must provide the VMM with proof that the pump meets all the required technical specifications.

Visibility and real-time monitoring

The application developed by TURCK displays the processed data in a user-friendly dashboard. The I/O module is integrated into the company's own network, allowing Van Hooste's team to easily access data in real time via a dashboard on mobile end devices. This allows deviations to be detected quickly and adjustments made if necessary. The solution from Van Hooste and Turck Multiprox has already shown in previous test bench tests that it meets both the strict requirements of the environmental authority and the high internal standards.

Optimized security and efficiency

Long-term documentation of operating parameters such as pressure, temperature and speed enables an assessment of operating efficiency over the entire life cycle of the plant and forms a sound basis for future optimizations. The pump solution has proven its efficiency and operational reliability in the test rig tests that have been carried out on a long-term basis: Initial measurement results show a significant reduction in fish mortality compared to conventional systems, which exceeds expectations with regard to the protection of local fish stocks. The successful test phase lays the foundation for the upcoming installation of the pump in the "De Blankaart" nature reserve, where it will shortly contribute to the protection and preservation of the fish population there. This makes the plant not only a showcase technological project, but also a sustainable model for comparable applications in water control and environmental engineering.

"The main strength of Van Hooste lies in the mechanical production of constructions and systems for water management," explains project engineer Brecht Van Damme. "The great added value of Turck Multiprox was the intensive cooperation and the complete takeover of the electrical part. They took care of the selection of suitable components as well as their programming. Together, we have achieved the goals we set out to achieve without any problems." The combination of mechanical precision and electronic control has resulted in a system that meets all technical and ecological requirements.

Customer | www.vanhooste.be

Hans De Craemer is a marketing manager | Turck Multiprox in Belgium