RFID Solution for Fail-Safe Material Logistics

KEB Automation is upgrading its driverless transport system with RFID technology to a fully automated and fail-safe material logistics solution

The Fast Read

In order to optimize its material logistics for assembly, the drive and automation technology specialist KEB Automation relies on RFID technology on the conveyor line and on automatic guided vehicles (AGV). The RFID solution from TURCK provides support for the automation of logistics processes and enables end-to-end transparency in materials flows for frequency converter production – without time-consuming manual work. What’s more, the solution makes a contribution to optimizing resource utilization and efficient use of warehouse capacities by means of automated pallet detection that ensures fast and reliable assignment to destinations.

Efficient material logistics involves far more than just managing production-related material flows. The primary goal is to optimize processes, to reduce costs and to ensure seamless processes. Transparency plays a crucial role when it comes to flexible and efficient management and control of transport operations. It demands a solution that links up all aspects of material logistics seamlessly. Achieving maximum productivity and efficiency and avoiding bottlenecks means ensuring there are information flows to accompany materials. This was the challenge facing KEB Automation within intralogistics at its electronics plant.

As a specialist in drive and control technology, KEB Automation develops, produces and distributes drives, as well as motors, transmissions, brakes, clutches and IIoT solutions worldwide. The company wanted to automate all non-value-creating warehousing processes at its production plant in Barntrup as far as possible. The catalyst for this was its purchase of a new factory hall at which it was able to plan all the details, right down to the production areas. From the very start, the goal was to replace the use of forklifts in the production area with automated guided vehicles.

“By using this RFID solution, we can intentionally allow a certain measure of chaos at this point in order to enable efficient work. As soon as a pallet leaves the area, which pallet it is and where it needs to be transported to is detected automatically.”

Phillip Hannesen | Digital Transformation Manager Produktion | KEB Automation

Warehouse management and pallet tracking using RFID technology

“The fully automatic identification and tracking of all pallets should be ensured using RFID labels on routes in the production area,” says Viktor Derksen, Head of Industrial Engineering at KEB, describing the main requirement of the application. The labels have a unique handling unit number (HU) that gives the load carriers their identity in SAP EWM. Printing the number as a barcode and plain text as well makes where, how and by whom a pallet is identified irrelevant. A movement order consequently always refers to an HU, and this across storage sites in different systems as well, carried out by the AGV or by conventional industrial vehicles. The exchange of information between the different systems and SAP is coordinated by means of middleware.

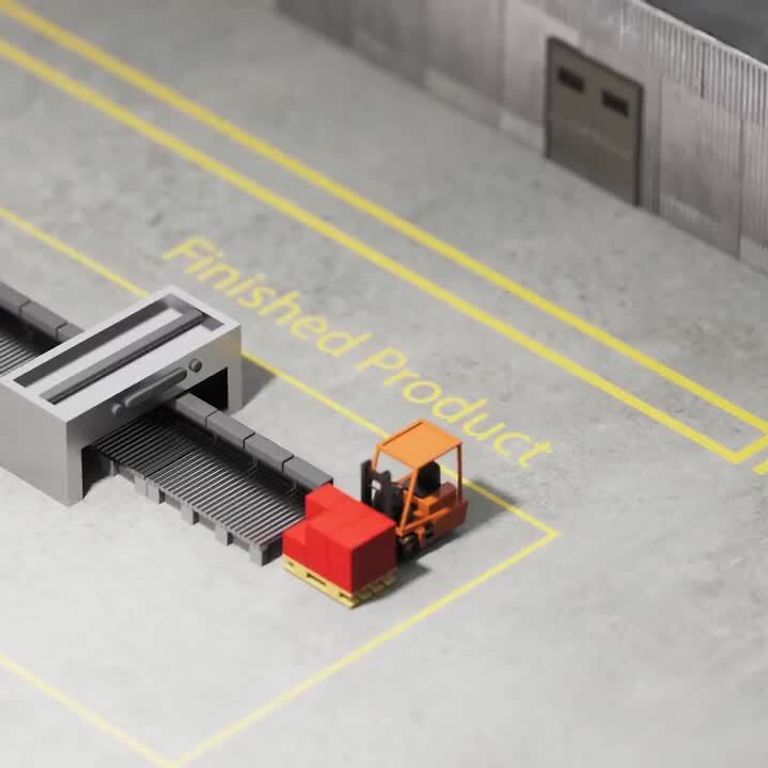

At the automated warehouse, the order-picked pallets are made available to the AGV by means of conveyor technology. Transport to all the factory halls for electronics is carried out from this starting point. Depending on the destination, the route covers several individual sections and temporary buffers. In the process, the individual movement orders are not only carried out by the AGV, but also by manual operation of industrial vehicles and stationary conveyor technology. Combined operation of these various intralogistics systems turns the precise tracking of pallets and the precise control of their movements into challenges that will be overcome by using RFID technology.

Optical ID solution unsuitable

The AGV requires consistent instructions and position information to determine its route. “When it’s a matter of one single pallet transport from one workplace to another, this is really straightforward,” explains Phillip Hannesen, Digital Transformation Manager Production at KEB in Barntrup. “It can become a problem in zones where several pallets are in temporary storage, and will be picked up later by another vehicle to be brought to another location. If the load carriers are mixed, then a consistent HU-to-bin assignment is no longer guaranteed, which is why the transport vehicle must have a way of identifying the loaded pallet at all times.”

To ensure reliable load identification, it is important that this can occur regardless of the alignment and positioning of the pallet. The TURCK UHF RFID system provides a solution for all application installation situations and achieves a read rate of almost 100 percent. The versatility and flexibility of the system becomes more evident when looking at the different usage cases at KEB.

“TURCK’s solution provides us with the transparency that we wanted without any time-consuming manual work. Detection of RFID tags is fully automatic, and completion or further processing of warehouse jobs from SAP Extended Warehouse Management therefore takes place at the same time.”

Viktor Derksen | Leiter Industrial Engineering | KEB Automatio

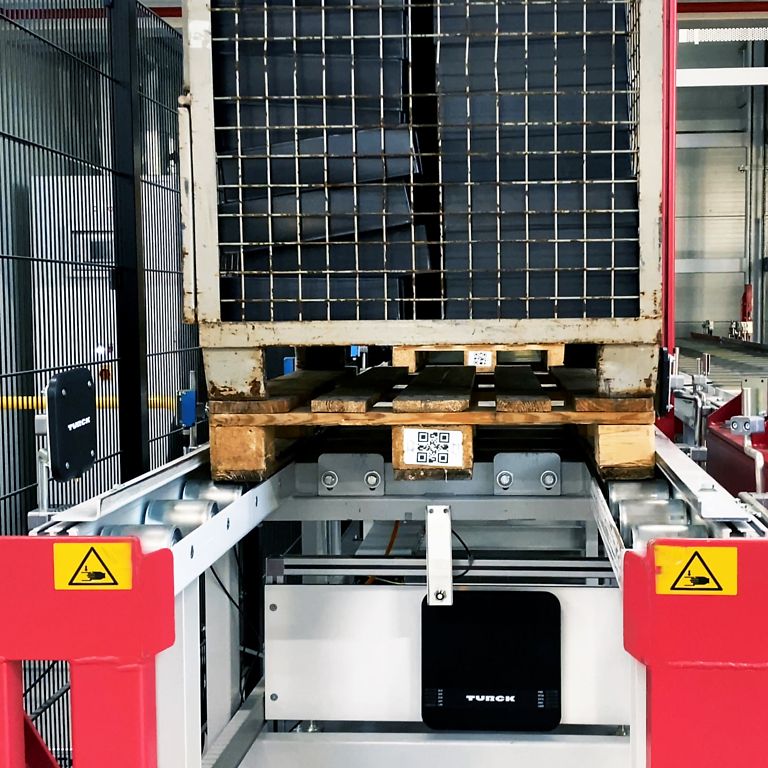

Pallet identification at the transfer station

The presence of the pallets at defined storage sites is checked at a transfer point for forklift trucks and AGVs. This involves use of the Q5X laser distance sensor from TURCK’s opto-partner Banner Engineering. Twenty Q5X sensors with a range of five meters are used to detect 20 pallets. The Q5X sensors secured at a height of three meters detect whether there are pallets at the transfer point for forward transport. Once the distance sensor has detected the presence of a pallet, a movement order is generated for the AGV. It picks up the pallet, moves through the RFID gate and then receives information about the HU from SAP EWM.

Before a movement order is generated, a check is made of whether the destination might already be occupied. Before the Q5X sensors were in use, the AGV had to drive to the destination to find out. In this case, the AGV waited in front of the blocked storage site until an employee cleared it. Now, the vehicle receives information about whether the destination is occupied in advance, and only starts moving when it is free – this avoids empty runs and waiting times, and ultimately improves performance.

A sensor initiates standardized communication between control and AGV by sending a 24-volt signal to the control when it detects the transport system. The PLC, in turn, uses the TCP/IP network to send the information to the AGV.

Pallet identification at full speed

External antennas are secured to each side of a factory gate that are connected to the UHF RFID reader. The external antennas ensure reliable detection of the RFID labels on the pallets, regardless of the alignment of the respective pallet on the AGV. Upon approaching the gate, the AGV sends a signal to start detection to the Q300 through the network.

There is a warehouse job in SAP EWM for the HU that the Q300 detects, this being the order to transport the load carrier from A to B. As soon as the AGV has passed the gate, it sends a request to the middleware.

Efficient identification in the near field too

A bridge with stationary pallet conveyor technology that has also been equipped with RFID technology connects two factory buildings. In contrast to use at the factory door, where RFID labels must be detected from long distances, this use case presents the challenge of only reading RFID labels in close proximity, this being at distances of up to around 10 cm. This is achieved with near-field antennas, which are set up to the left and right of the pallet conveyor system. These near-field antennas only detect the RFID label of the pallet that is situated directly in front of them.

At the transfer lines, the conveyor system communicates with the AGVs to ensure a flawless transfer process. When the pallet is set down, the AGV sends a request to the middleware to identify the pallet using the Q300 reader’s near-field antennas. This information is sent back to the middleware, which determines the warehouse jobs for this pallet based on the data from the SAP EWM. Once the pallet has been set down at the transfer point, the conveyor system transports the pallet to the next factory building, where RFID is once again used to detect it.

Full transparency

The RFID solution gives KEB the decisive advantage of end-to-end transparency. Where a pallet is located can be viewed at any time – whether it is still on the conveyor system, has been picked up by the industrial vehicle, or has already arrived at its destination. There are a number of situations in which it is possible to automate the confirmation of EWM warehousing jobs by using RFID. Manual operation of mobile end devices supplements this. “TURCK’s solution provides us with the transparency we wanted without time-consuming manual work,” says Derksen. “Detection of RFID tags is fully automatic, and completion or further processing of warehouse jobs from SAP Extended Warehouse Management therefore takes place at the same time.”

Agile warehouse management allows controlled chaos

Another advantage of the RFID solution is that it allows mixed traffic in the factory building This means that both the AGVs and employees with a pallet truck or forklift truck can be loading or unloading in the staging area at the same time. There is no need for separate storage site management, as each pallet can be identified at each fork. “By using this RFID solution, we can intentionally allow a certain measure of chaos at this point in order to enable efficient work. As soon as a pallet leaves the area, which pallet it is and where it needs to be transported to is detected automatically,” explains Hannesen, who also underlines the great cooperation with TURCK: “The service provided by TURCK and the short communication paths make teamwork efficient; we are happy to rely on this trust-based and well established partnership."

Outlook

Due to the successful use of AGVs with the TURCK RFID technology, additional extensions are planned. Waste disposal has also been successfully integrated into the system: Containers in which used cardboard is collected are picked up by the AGVs. There are plans to have these containers transfered directly to a new waste compactor, which would fully automate disposal.

What’s more, the laser distance sensors will be equipped with IO-Link modules made by TURCK, which will be able to perform control functions of their own accord using the TURCK ARGEE logic software. These include, for example, the detection and evaluation of the sensor values. They will also manage communication required with middleware or AGVs in an autonomous and efficient way, which results in an extremely lean overall solution.

Customer | www.keb-automation.com

Phil Whorton is responsible for Customer-Specific System Solutions at the Application Service Center at TURCK