Building blocks for intelligent material flow

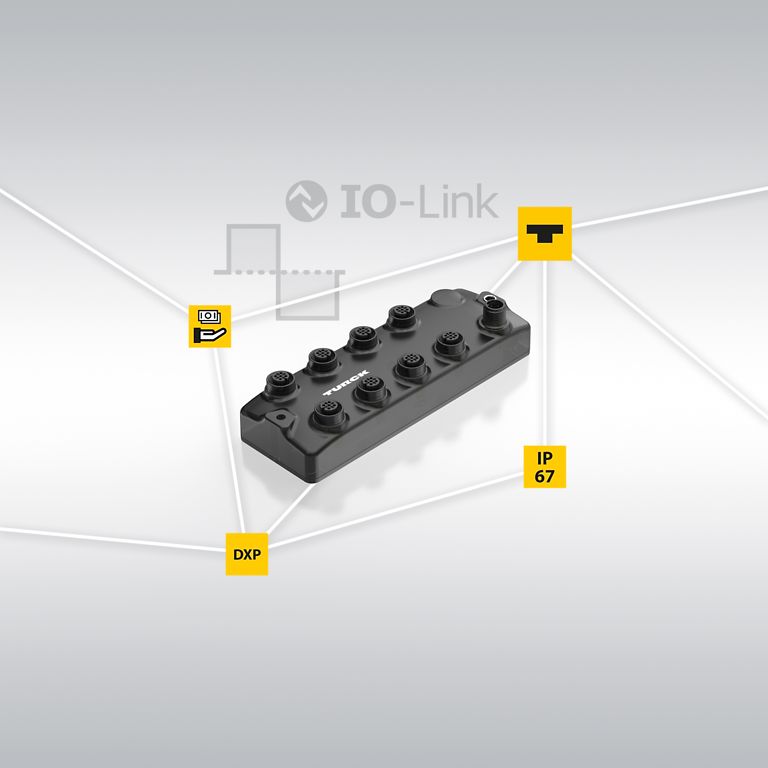

With IP67 solutions from TURCK, you can control intralogistics directly in the field — keeping your system ready for new developments

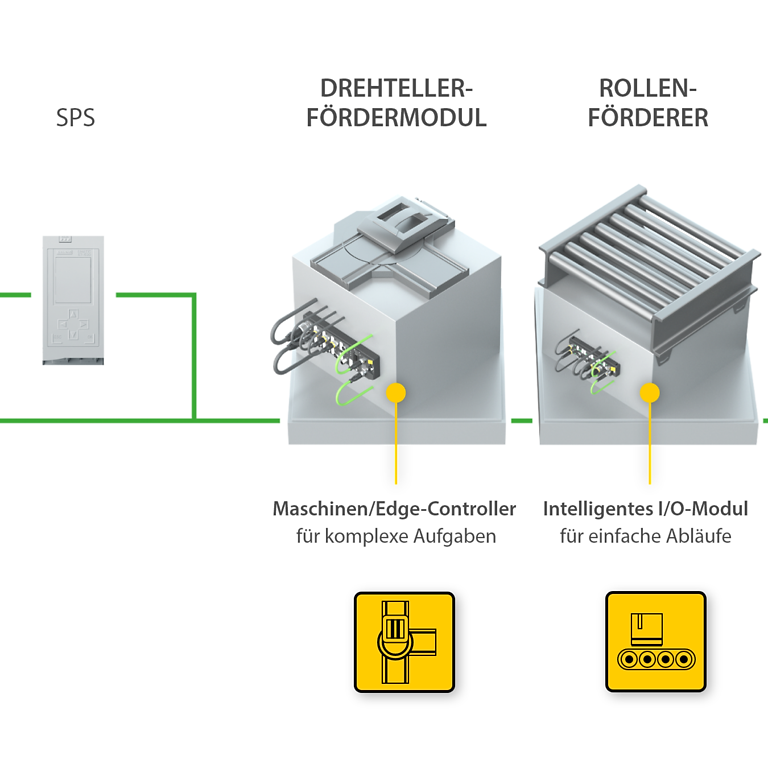

Modular intralogistics with decentralized automation solutions

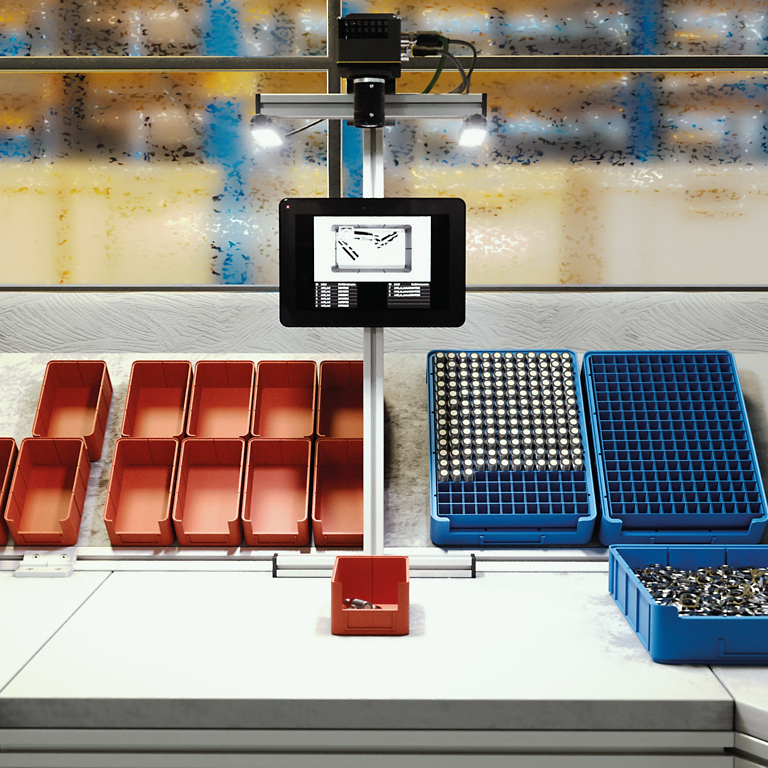

Digitalization, artificial intelligence and, last but not least, growing e-commerce are driving the pace of innovation in in-house logistics to new heights. Fully automated transport management systems guide material to its destination in an autonomous and efficient manner – whether in production, picking or goods issue. This is made possible by machine modules with decentralized control logic. They shift the necessary intelligence into the immediate vicinity of the conveyor line, thus significantly reducing the time-to-market of new plants, among other things.

Modular design principle instead of a rigid line

TURCK's compact IP67 Edge Controllers or block I/O modules control the processes of a logistics plant decentrally. If necessary, the autonomous modules can still communicate with a main control system or a control system via multiprotocol Ethernet, using PROFINET, EtherNet/IP, or Modbus TCP.

Machines/Edge Controllers – complex control tasks

Decentralized control instead of top-down management: in a smart conveyor system made up of self-propelled transport modules, TURCK's TBEN-L-PLC Codesys 3 controllers coordinate an entire subsystem – networked via Ethernet UDP, the modules operate with swarm intelligence. Due to its variety of interfaces, the compact PLC can be integrated as a master or slave in different networks. As an Edge Controller, it can pre-process data and forward it specifically to higher-level systems such as MES, ERP or a cloud – for example, this enables effective condition monitoring on mobile end devices.

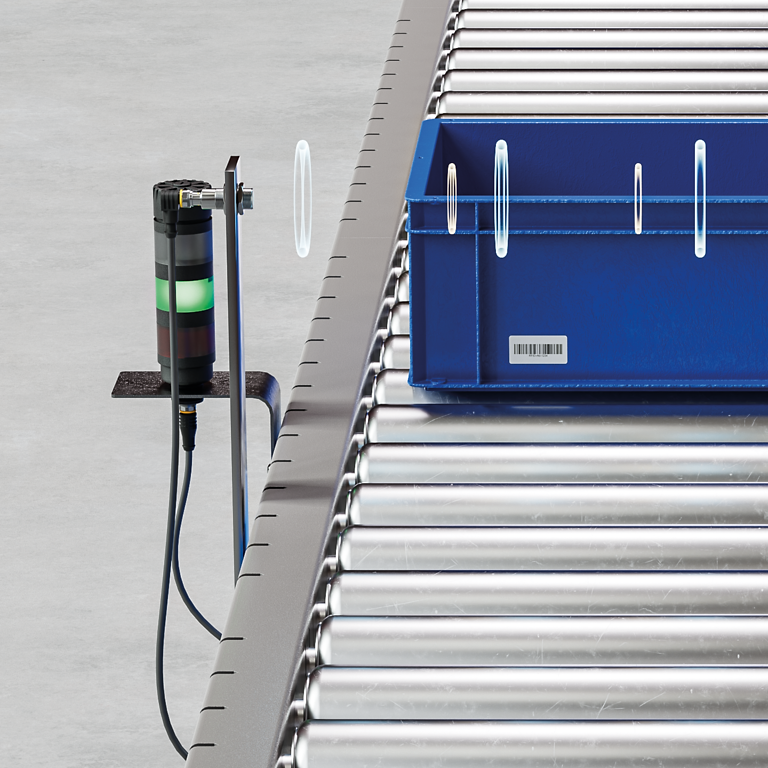

Intelligent I/O module – process sub-functions autonomously

Using the free ARGEE programming interface, users can use the full potential of TURCK's standard fieldbus modules to process small to medium-sized control tasks. On a roller conveyor, an I/O module then directs the interaction between a photoelectric sensor and the roller movement, for example. This prevents users from damaging transported material by collisions. If desired, data can flow directly into the MES without going through a higher-level PLC, for example via Modbus TCP.

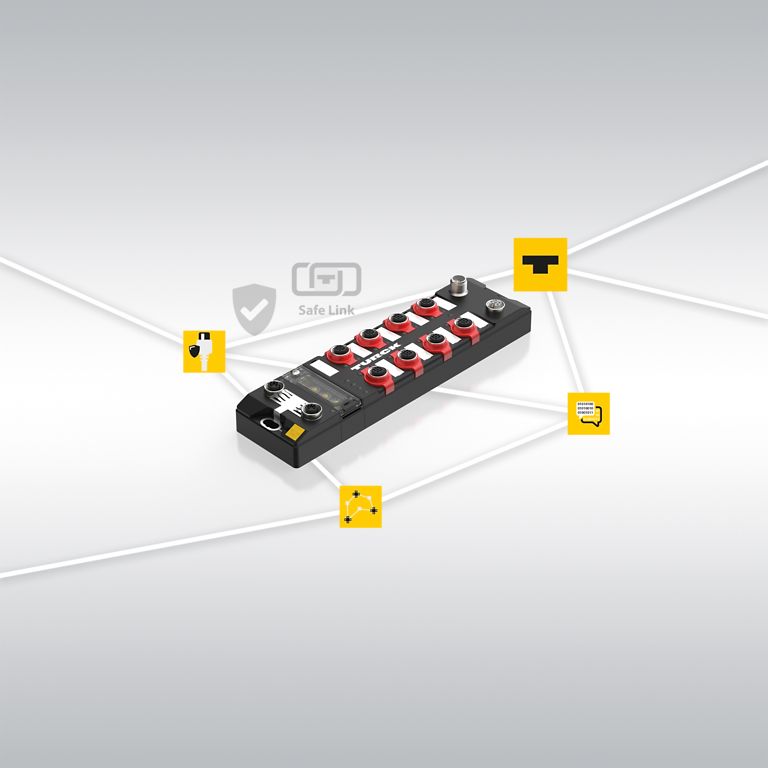

Safety hybrid module – independent safety control

Even safety functions can be controlled with safety I/O modules in the immediate vicinity of the danger zone. Decentralized signal processing allows shorter cycle times – for a potentially higher conveying speed. In addition, the safety functions in non-affected parts of the plant are retained if an unplanned event such as a cable break occurs. Users configure the safety functions of the safety I/O modules with the versatile TURCK Safety Configurator.

Take advantage of modular automation

Short time-to-market

- Rapid delivery thanks to modular design principle

- Test machine modules offline in advance

- Reuse existing modules

- Respond dynamically to new requirements

Fast commissioning

- Easy wiring thanks to IP67 components and quick connectors

- In-house wiring and module tests reduce installation time on site

- Flexible combination of machine modules

Lower costs

- Reduced hardware requirements when no switch cabinets or controls are used

- Reduced wiring costs thanks to IP67 I/O systems directly in the field

- Reduced labor costs during commissioning

- Reduced control capacity requirements and more data processed with fewer IP addresses

High performance

- Load relieved on the main control system thanks to outsourcing of functions

- Reduced data exchange with the central PLC allows shorter cycle times and faster processing

- More capacity for logic calculations through reduced network connections

More solutions for modular intralogistics

Form your own picture of successfully implemented intralogistics applications and see the advantages of modular system design for yourself.