Webinar: Digital conveyor technology: flexible, scalable, available!

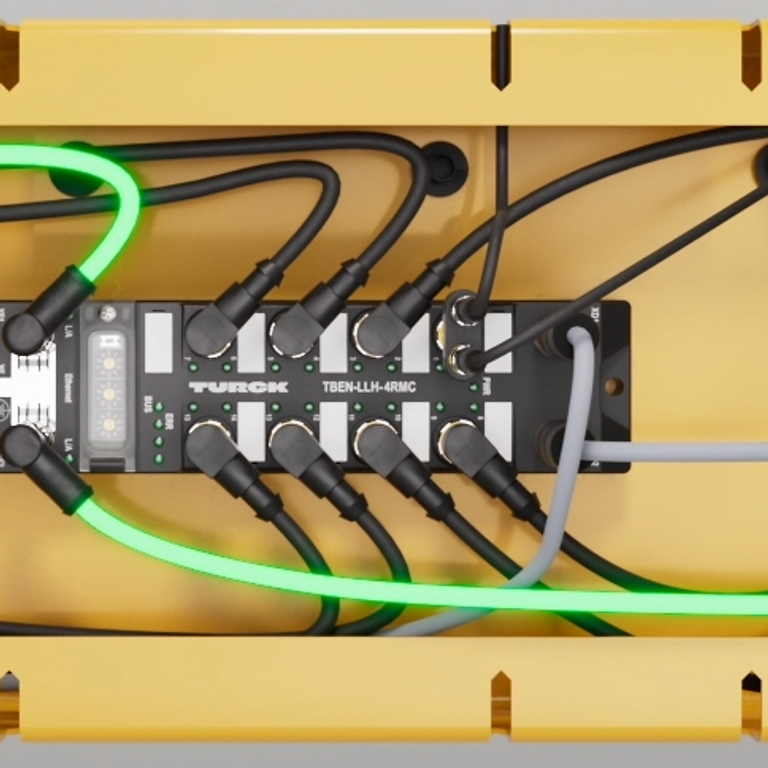

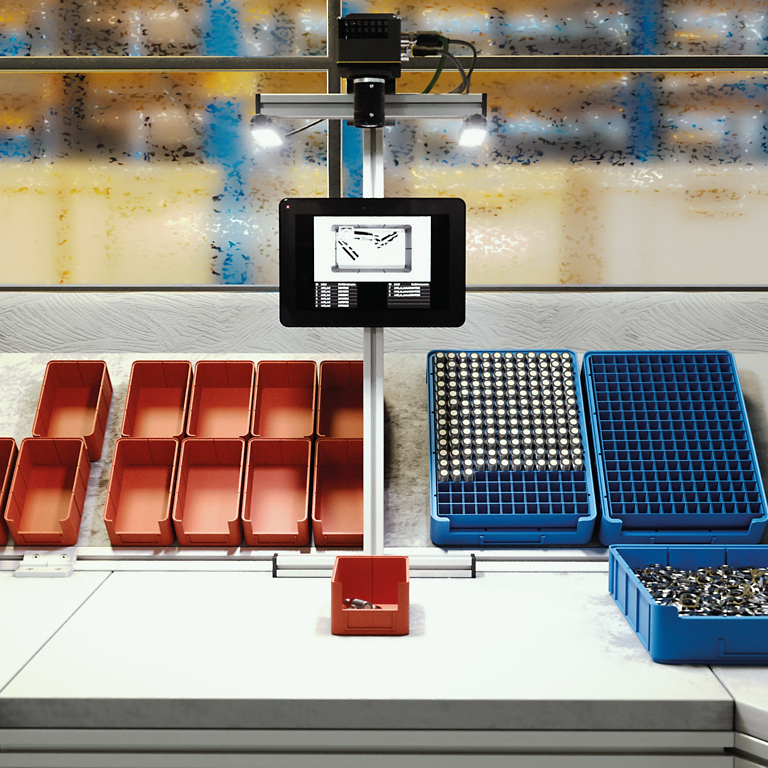

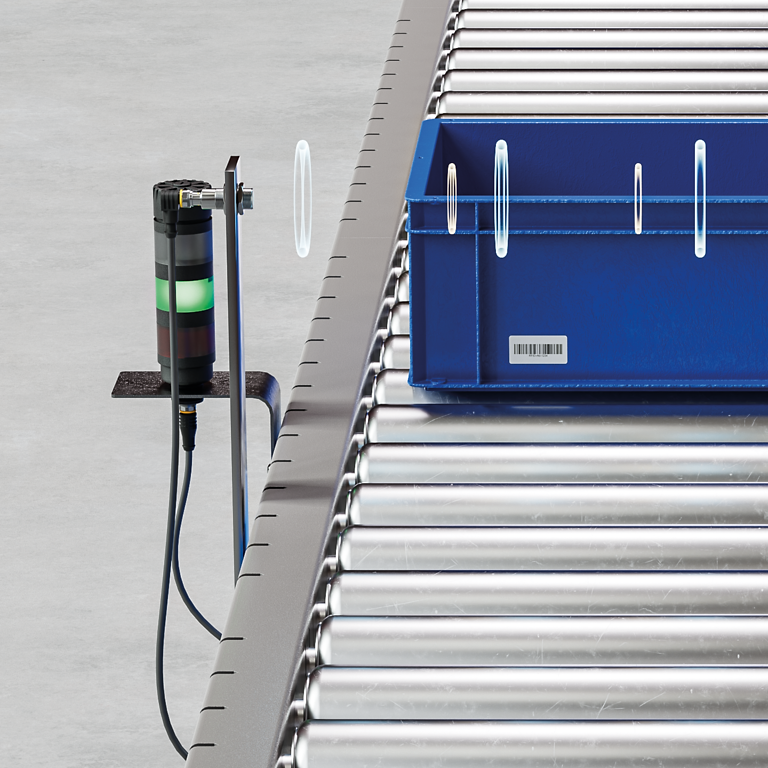

Rapidly changing customer requirements, more complex supply chains and increasing pressure to achieve efficiency are key challenges in intralogistics. Learn how modularization and digitalization of your conveyor technology can help you to overcome these hurdles in this English-language webinar recording. Discover how smart automation technology optimizes your processes, increases flexibility, improves scalability and maximizes availability.